Conductor Stringing Equipment

Conductor stringing equipment consists of specialized tools and machinery used to install and tension overhead conductors (wires) on power transmission and distribution lines. These tools ensure the conductor is pulled, guided, and tensioned safely and efficiently to maintain proper sag and alignment, preventing damage during installation.

-

: These are the core machines that apply controlled tension and pulling force to conductors. For example, heavy-duty hydraulic tensioners with capacities up to 24 tons (240 kN) and pullers with up to 25 tons pulling force are used for multi-conductor stringing operations, including bundled conductors. Features often include closed hydraulic circuits with infinitely variable tension control, automatic brakes for safety, wear-resistant bullwheel linings (e.g., MC nylon), and hydraulic cooling systems.

-

: These guide conductors and pulling lines over towers and obstacles, reducing friction and preventing conductor damage. High-quality stringing blocks use ball bearings for efficient sheave rotation, minimizing pulling losses (around 2% per block). They come in various configurations, such as single, double, triple, and multi-sheave blocks, made from materials like cast nylon or aluminum alloy for durability and smooth operation.

-

: Strong, low-elongation ropes or steel pilot wires are used to pull conductors through stringing blocks. Proper selection of pulling lines is critical to avoid oscillations or tension fluctuations during stringing.

-

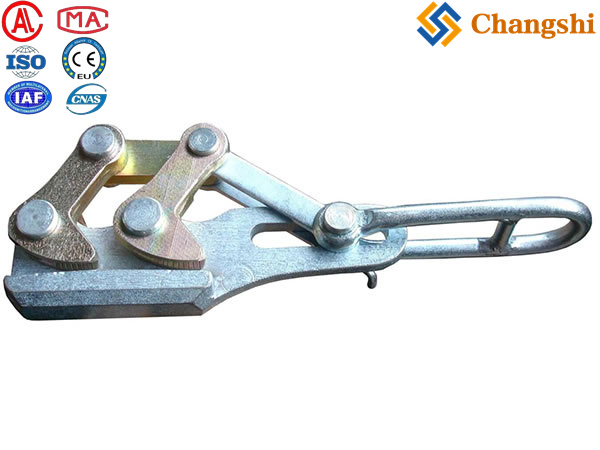

: These clamps securely hold conductors or earth wires during stringing operations, available in automatic or manual types and designed for various conductor sizes and types.

-

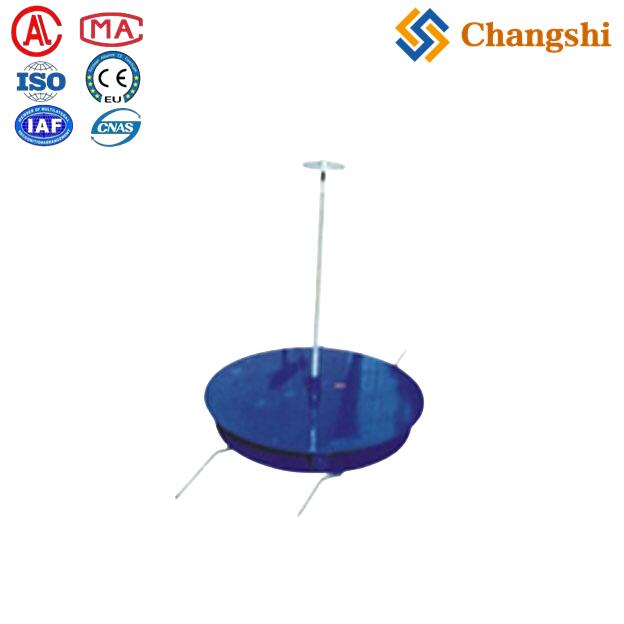

: Reel stands with hydraulic or mechanical brakes control conductor payout from reels, while winches assist in pulling conductors over long distances or difficult terrain.

-

: These prevent conductor twisting and birdcaging during pulling, ensuring conductor integrity.

-

Equipment is designed for a wide range of conductor diameters (up to 40 mm or more) and stringing speeds (up to 5 km/h).

-

Hydraulic tensi