Wire Stringing Equipment

Wire stringing equipment refers to the specialized tools and machines used for pulling, tensioning, installing, and aligning conductors (wires) in overhead transmission and distribution lines. These tools are essential for safely and efficiently stringing electrical wires and cables such as ACSR, OPGW, AAC, and other conductors on power and telecommunication lines.

-

: These machines provide controlled pulling and tensioning forces to string conductors over long distances. They often feature hydraulic systems with variable tension control and automatic safety brakes to prevent conductor damage. For example, hydraulic cable tensioners with capacities around 30 kN (3 tons) are common and include features like wearproof bullwheels and infinitely variable tension control.

-

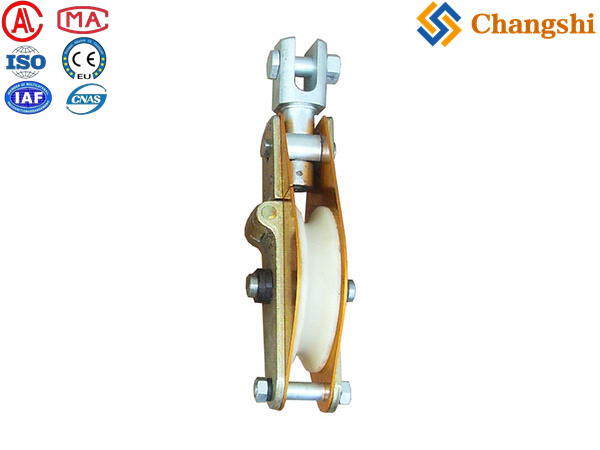

: Pulleys and blocks used to guide the wire through the towers and reduce friction during pulling, protecting the conductor from damage.

-

: Devices that securely grip the conductor and allow it to rotate freely during pulling to avoid twisting and damage.

-

: Reel stands, motorized winches, and cable-laying machines that facilitate the controlled unwinding and tensioning of cable reels.

-

: Support structures and rollers that assist in lifting and guiding conductors during stringing operations.

-

: Used for fine adjustments of conductor tension and alignment.

-

Wire stringing equipment is designed for overhead line construction and maintenance, including high-voltage transmission lines, power distribution lines, and telecommunication cables.

-

Modern machines incorporate digital controls and safety features such as automatic overload protection, hydraulic released brakes, and real-time tension monitoring to enhance safety and efficiency.

-

Equipment can handle various conductor types and sizes, including bundled subconductors pulled simultaneously with equal tension.

-

Some advanced systems include helicopter-assisted stringing machines that improve safety and efficiency in difficult terrain.