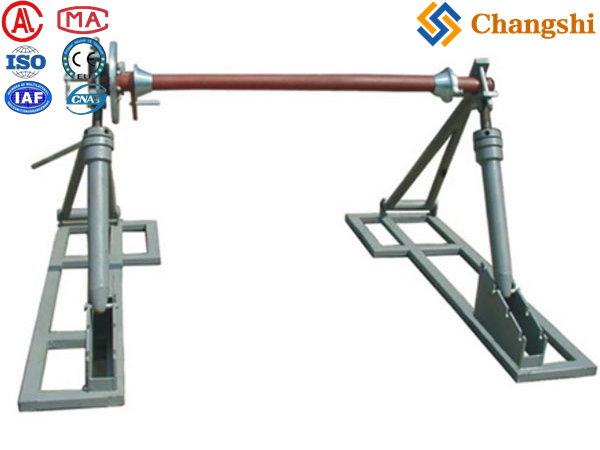

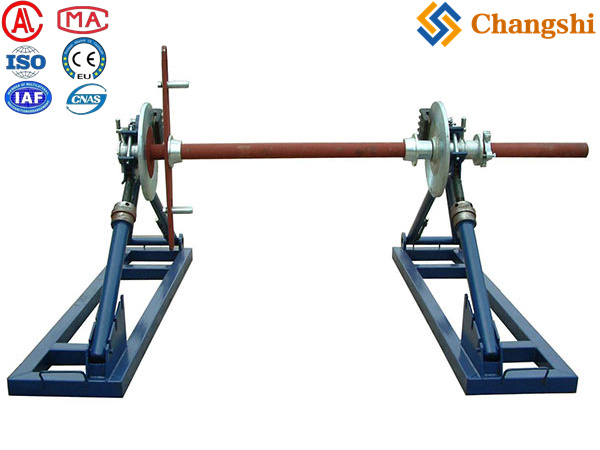

Heavy-Duty Hydraulic Braking Reel Stands

Heavy-duty hydraulic braking reel stands are specialized equipment designed to handle the largest and heaviest reels of conductor or cable used in high-voltage transmission line stringing. Their "heavy-duty" and "hydraulic braking" features are crucial for managing the significant forces and ensuring precise control during the payout of massive cables.

What Makes Them "Heavy-Duty" and "Hydraulic Braking"?

1. Heavy-Duty:

Capacity: They are built to support enormous weights, typically ranging from 5 tons to 20 tons or even more per pair. This accommodates the massive reels used for large-diameter conductors (e.g., ACSR, bundled conductors) or long lengths of underground cable.

Construction: The frames are constructed from exceptionally thick and robust welded steel, often with reinforced sections, gussets, and wide, stable bases. They are designed to withstand not only the static weight but also dynamic stresses during payout and braking, and often rough handling on job sites.

Spindle/Arbor Bar: The central spindle, which passes through the reel, is a solid, large-diameter steel shaft, precisely machined and heat-treated to prevent bending or failure under extreme loads.

Durability: Finished with durable coatings (e.g., heavy-duty paint, galvanization) for corrosion resistance in harsh outdoor environments.

2. Hydraulic Braking:

Precise Tension Control: This is the defining feature. Unlike simpler mechanical brakes (which rely on friction pads and hand levers), hydraulic braking systems offer significantly more precise, consistent, and powerful control over the back-tension applied to the conductor.

Hydraulic Calipers and Discs: The braking mechanism typically involves large disc brakes (similar to vehicle brakes) with hydraulic calipers. These calipers are actuated by hydraulic pressure, clamping down on the brake disc to create resistance.

Hydraulic Pump: The hydraulic pressure is generated by a manual hand pump (for smaller/medium units or fine adjustment) or, for the heaviest-duty units, an external hydraulic power unit (HPU) which provides continuous, powerful, and often automated control.

Accumulator Systems: Some advanced systems include a hydraulic accumulator. This acts as a reservoir of hydraulic pressure, ensuring a smooth and consistent brake pressure application even with slight fluctuations in the pulling force or reel rotation, preventing jerky movements.

Fail-Safe Mechanisms: High-quality hydraulic braking systems often have fail-safe features that automatically apply the brake in case of hydraulic pressure loss or power failure, preventing uncontrolled payout.

Remote Control (Optional): When connected to an HPU or integrated with a tensioner, the hydraulic braking can often be controlled remotely from the tensioner's control panel, allowing the operator to fine-tune back-tension precisely.

Advantages for Power Line Stringing:

Optimal Tension Management: Essential for maintaining the correct back-tension during stringing, which directly impacts the quality of the sag and prevents over-spinning, bird-caging, or damage to expensive conductors.

Safety: Precise control significantly reduces the risk of accidents caused by runaway reels or sudden uncontrolled payout.

Efficiency: Smooth and controlled unwinding minimizes delays, tangles, and re-work.

Conductor Protection: Consistent tension and controlled payout reduce stress on the conductor, preserving its integrity and lifespan.

Larger Capacity: Allows the use of larger, heavier reels, reducing the number of splices required and minimizing setup time.