Cable Cutters & Crimpers

Cable cutters and crimpers are fundamental tools for any power utility worker, from linemen and electricians to technicians in substations and underground vaults. They are used for preparing and terminating cables and conductors of various sizes and materials.

Cable Cutters:

Cable cutters are designed to make clean, efficient cuts through conductors. The type of cutter used depends heavily on the conductor's material, diameter, and whether it contains steel reinforcement.

Types of Cable Cutters for Power Lines:

Manual Hand Cable Cutters:

Description: Resemble heavy-duty pliers or shears with sharp, hardened blades. They operate on leverage.

Application: Suitable for smaller copper and aluminum cables (e.g., up to 70mm² or around 2/0 AWG), especially in residential, light commercial, and distribution applications where occasional cuts are needed.

Advantages: Lightweight, portable, inexpensive.

Disadvantages: Requires significant hand force for larger cables, can cause hand fatigue.

Examples: Greenlee, Klein Tools, Knipex. (Li Yao Industrial and Camsco Electric in Taiwan likely manufacture/distribute these).

Ratcheting Cable Cutters:

Description: Feature a ratchet mechanism that multiplies the force applied by the user. The blades cut in incremental steps as the handles are repeatedly squeezed. Many models have telescopic handles for increased leverage.

Application: Ideal for thicker copper and aluminum cables (e.g., up to 500mm² or 1000 kcmil) that are too large for manual cutters but don't require hydraulic power. They are very common for industrial and utility work on distribution lines. Some specialized ratchet cutters can handle ACSR (aluminum conductor steel-reinforced) or guy wire.

Advantages: More powerful than manual cutters, less physical effort, compact.

Disadvantages: Slower than hydraulic cutters, can still be strenuous for very frequent use or very large cables.

Examples: Greenlee, Klein Tools, Izumi, Knipex.

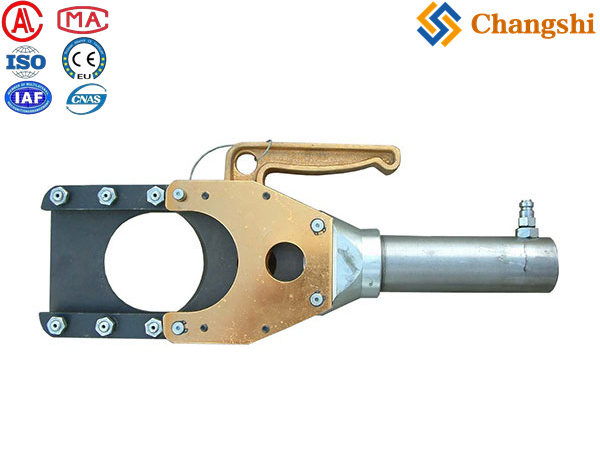

Hydraulic Cable Cutters:

Description: These tools use hydraulic pressure to generate immense cutting force, making them capable of slicing through very large or tough conductors, including armored cables, steel wire rope, and steel-reinforced conductors (ACSR). They come in various configurations:

Manual Hydraulic Cutters: Self-contained units where the operator pumps a handle to build hydraulic pressure for the cut.

Battery-Powered Hydraulic Cutters: Integrate a small electric motor and hydraulic pump, powered by a rechargeable battery (e.g., 18V/21V Li-ion). Operated with a button.

Remote Head Hydraulic Cutters: A separate cutting head connected by hoses to an external hydraulic pump (manual, electric, or engine-driven). These provide the highest cutting forces.

Application: Essential for high-voltage transmission lines, underground cables, large distribution feeders, and any application involving steel-reinforced or armored cables.

Advantages: Extremely powerful, minimal operator effort, clean cuts, suitable for high-volume or heavy-duty cutting.

Disadvantages: Higher cost, battery management for powered versions, less portable for remote-head systems.

Examples: Cembre, Burndy, Greenlee, Klauke, Izumi, Milwaukee Tool, Holmatro, Tesmec. (Camsco Electric, Elecmit Electrical, and potential direct imports from Chinese manufacturers like Dongfang are sources in Taiwan).

Key Considerations for Cable Cutters:

Cable Material & Diameter: Crucial for selecting the right cutter. Always check the tool's maximum cutting capacity and compatibility with copper, aluminum, or steel.

Cutting Action: Guillotine, scissor, or shear action.

Insulation: Ensure blades are suitable for cutting insulated cables without damaging the insulation (or for removing it as a separate step).

Safety Features: Pinch guards, blade guards, locking mechanisms.

Crimpers (Compression Tools):

Crimpers are used to create secure, low-resistance electrical connections by deforming a connector (lug, splice, ferrule) onto a conductor. This process is critical for both mechanical strength and electrical integrity.

Types of Crimpers for Power Lines:

Manual Hand Crimpers:

Description: Operated by hand, using leverage or a simple mechanism to apply force.

Application: Primarily for smaller wire gauges and terminals, like those found in control panels, internal wiring, and lighter distribution connections. Some heavier-duty manual crimpers can handle battery lugs.

Advantages: Portable, inexpensive, simple to use.

Disadvantages: Limited force, not suitable for larger power conductors or heavy-duty splices.

Examples: Klein Tools, Greenlee, various manufacturers specializing in electrical wiring accessories. (HCI's RJ45 crimper is a good example of a "manual hand crimper" but for data cables, not power lines. Li Yao Industrial and Camsco Electric in Taiwan offer general hand crimping tools).

Ratcheting Crimpers:

Description: Incorporate a ratchet mechanism that ensures a full crimp cycle before the jaws release, guaranteeing consistent and reliable connections.

Application: Popular for electricians working with insulated and non-insulated terminals, splices, and ferrules on a range of wire gauges, typically up to 8 AWG or sometimes larger.

Advantages: Consistent crimps, reduced operator fatigue compared to non-ratcheting manual crimpers, interchangeable dies for versatility.

Disadvantages: Still manual effort, limited by human strength for very large conductors.

Examples: Ideal Industries, Greenlee, Klein Tools, Sargent.

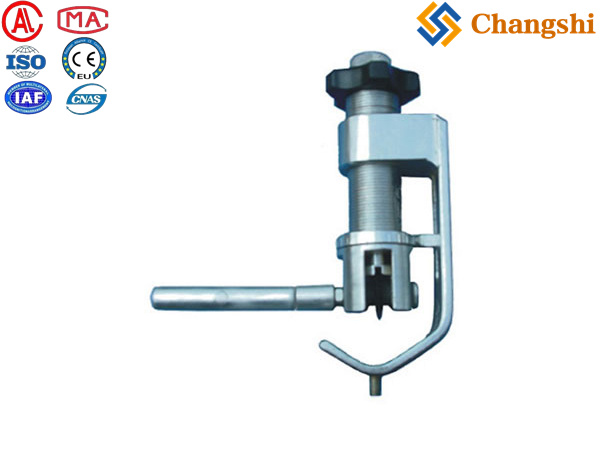

Hydraulic Crimpers (Compression Tools):

Description: As extensively discussed in the previous response, these are the workhorses for power line applications. They use hydraulic pressure to apply massive force.

Types:

Manual Hydraulic Crimpers: Self-contained, hand-pumped for medium conductors.

Battery-Powered Hydraulic Crimpers: Motorized, battery-operated for medium to large conductors (up to 630mm² or 1000 kcmil, sometimes higher). These are very popular due to their portability and power.

Remote Head Hydraulic Crimpers with External Pumps: Provide the highest forces for very large transmission conductors and specialized applications.

Application: Essential for jointing (splicing) overhead conductors, applying dead-end connectors, and connecting large cables in substations or underground.

Advantages: High force, consistent crimps, low operator effort (especially powered versions), critical for reliable high-current connections.

Disadvantages: Higher cost, requires specific dies for each connector/conductor combination.

Examples: Cembre, Burndy, Greenlee, Klauke, Huskie Tools, Izumi, Milwaukee Tool, Tesmec, Dongfang. (Marlow Crimping Tools and Elecmit Electrical are key Taiwanese manufacturers/suppliers).

Key Considerations for Crimpers:

Conductor and Connector Type/Size: Crucial for selecting the correct tool and die set. Incorrect dies lead to unreliable and unsafe connections.

Crimping Force/Capacity: Must match the requirements of the connectors.

Die System: Ensure easy die interchangeability and availability of a full range of dies.

Ergonomics & Weight: Especially important for handheld and battery-powered tools used frequently.

Calibration & Maintenance: Hydraulic crimpers, especially, need regular calibration and maintenance to ensure they deliver the specified force.