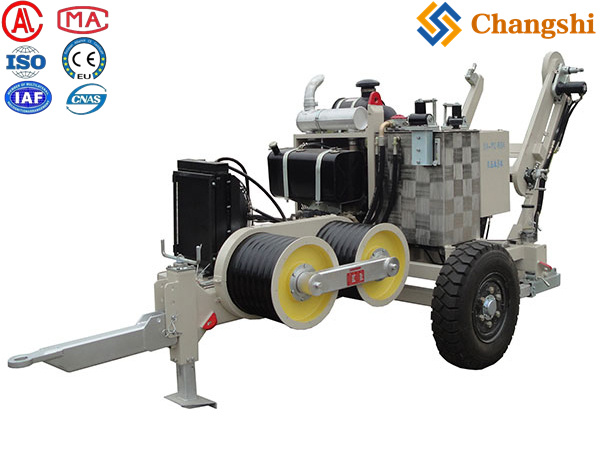

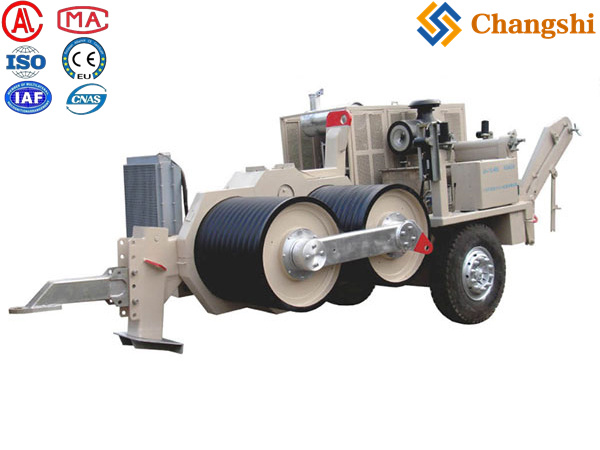

Multi-Drum Pullers for Heavy Cables

Multi-drum pullers are specialized heavy-duty machines primarily used for underground cable installation, particularly for large, heavy power cables, typically in the medium to extra-high voltage range (MV, HV, EHV, UHV). While bullwheel pullers are dominant in overhead line stringing, drums are often preferred for underground applications due to the need to coil the cable neatly back onto a drum as it's pulled.

How Multi-Drum Pullers Work for Heavy Cables:

Instead of bullwheels, multi-drum pullers feature multiple separate pulling drums that are powered by a hydraulic system. Here's a breakdown:

Multiple Drums: The key feature is the presence of several (e.g., two, three, or four) large-capacity steel pulling drums. Each drum can operate independently or be engaged/disengaged for single or multi-drum pulling.

Cable Management: The heavy cable is spooled onto one or more of these drums as it's pulled through conduits, ducts, or trenches.

Hydraulic Power & Control: Similar to bullwheel pullers, a robust hydraulic system driven by a powerful diesel engine provides the pulling force. Each drum typically has its own mechanical clutch and hydraulic brake, allowing for precise and independent control of each cable being pulled.

Levelwind Systems: Crucial for multi-drum pullers, these systems (often operator-controlled post-style or automatic) ensure that the cable is wound evenly and neatly onto the drums, preventing tangling and damage.

Monitoring and Safety: Equipped with advanced features:

Line Pull/Tension Monitoring: Real-time display and recording of the pulling force on each drum.

Speed Control: Infinitely variable speed control for delicate and heavy pulls.

Overload Protection: Automatic systems to prevent exceeding the cable's maximum pulling tension.

Braking Systems: Powerful braking systems (e.g., hydraulically controlled disc brakes or band-style drum brakes) on each drum to maintain tension and stop safely.

Operator Cabins: For very large machines, climate-controlled operator cabins might be included for comfort and safety during long operations.

Key Advantages and Applications for Heavy Cables:

Underground Installation: Their primary application. They are ideal for pulling large-diameter, heavy power cables through long stretches of underground conduit systems in urban or industrial areas.

Multiple Cable Runs: The ability to pull multiple cables simultaneously (e.g., three phases of an underground circuit) or sequentially without reconfiguring the entire setup significantly increases efficiency.

High Pulling Capacity: Designed to handle the immense pulling forces required for very heavy cables, especially when friction is high in ducts or over long distances. Capacities can range from a few tons up to tens of tons per drum.

Controlled Laying: Drums allow for precise control of the cable as it's spooled, minimizing bending radius violations and preventing damage.

Recovery and Storage: The drums also serve for neat recovery and storage of the pulled cable, or the pulling rope itself.

Distinctions from Bullwheel Pullers:

Pulling Mechanism: Multi-drum pullers spool the cable directly onto a rotating drum, whereas bullwheel pullers use friction around large, grooved wheels to move the conductor without necessarily spooling it.

Application Focus: Multi-drum pullers are predominantly for underground heavy cable pulling, while bullwheel pullers are largely for overhead conductor stringing.

Cable Type: Drum pullers are excellent for uncoiling and recoiling rigid, heavy cables that need to be laid in specific lengths or are destined for underground ducts.