Gin Poles & Derrick Cranes for Tower/Pole Work

Gin poles and derrick cranes are specialized lifting devices used in power utility work, particularly for the erection, maintenance, and dismantling of transmission and distribution line structures (towers and poles). While they both serve a similar purpose of lifting heavy loads, they differ significantly in their design, mobility, and application.

Gin Poles: The Incremental Lifter

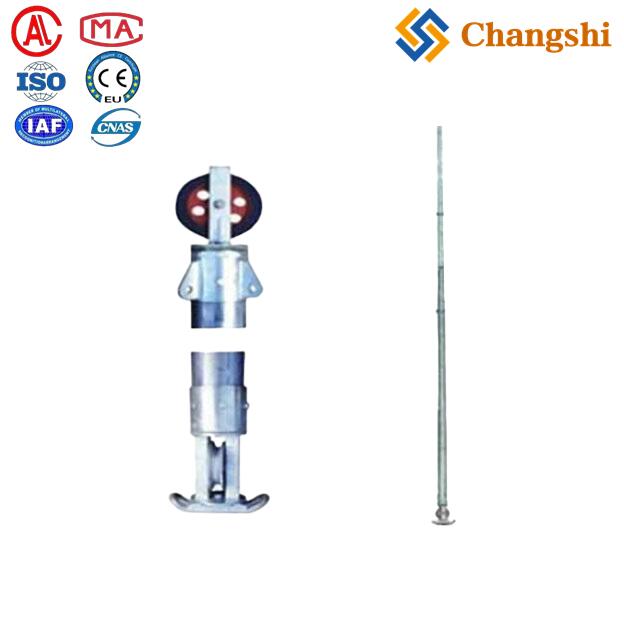

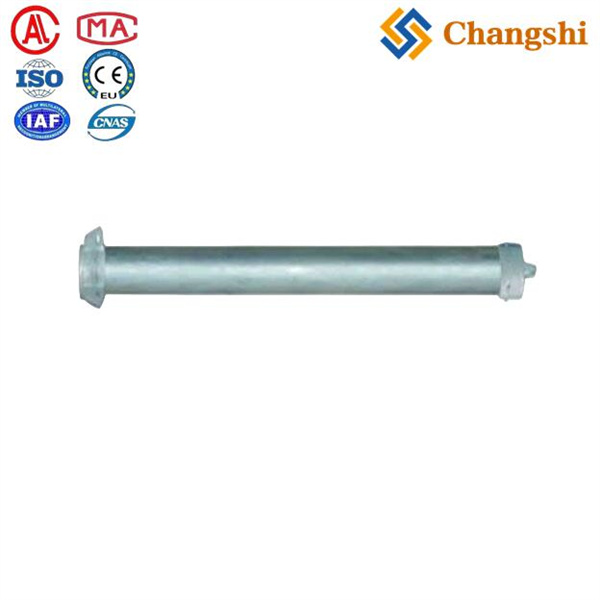

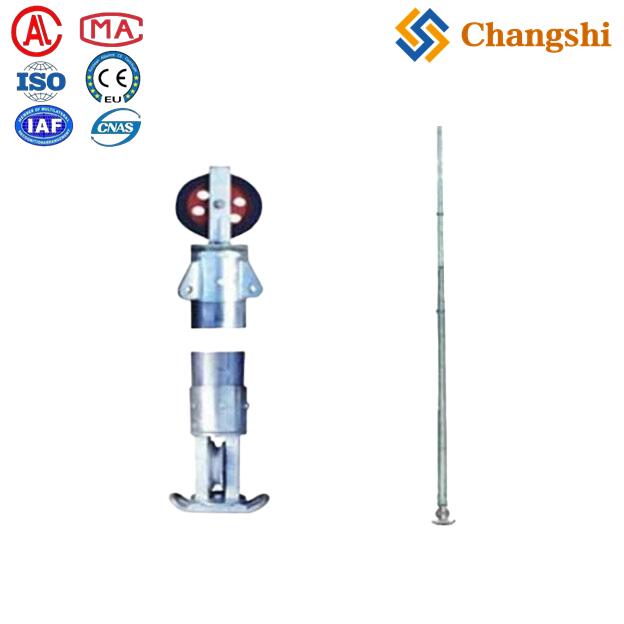

A gin pole is a simple, temporary, and highly versatile lifting device consisting primarily of a single, long, self-supporting mast or boom, often made of lightweight aluminum alloy (lattice or tubular design) or steel. It is supported by guy wires (stay ropes) and uses a block-and-tackle system or winch at its upper end to lift loads. Its bottom end is usually hinged or braced.

How Gin Poles are Used in Power Utility:

Tower Erection (Jumping the Pole): This is a primary use. For very tall transmission towers, it's often not feasible to use conventional cranes. A gin pole is erected on the ground to lift the first section of the tower. Once that section is bolted into place, the gin pole is "jumped" (lifted and re-attached) to the top of the newly erected section to lift the next section. This process is repeated until the entire tower is assembled. This makes them ideal for remote or difficult-to-access terrain where large cranes cannot operate.

Pole Setting: Especially for taller or heavier utility poles where a digger derrick's reach might be insufficient, or for areas inaccessible to trucks.

Lifting Heavy Components: Used to lift and position heavy components like large insulators, transformer banks, or specialized equipment onto poles or towers.

Antenna and Line Installation: Critical for installing antennas, microwave dishes, and overhead lines onto existing towers.

Cost-Effectiveness & Maneuverability: They are more cost-effective than large cranes for specific applications and are highly maneuverable in tight or remote spaces.

Power-Independent: Many gin pole operations rely on manual winches or separate winching systems, meaning they don't require their own onboard power source, making them suitable for remote locations.

Key Features of Gin Poles:

Materials: High-strength aluminum alloy (lightweight for transport and manual handling) or steel.

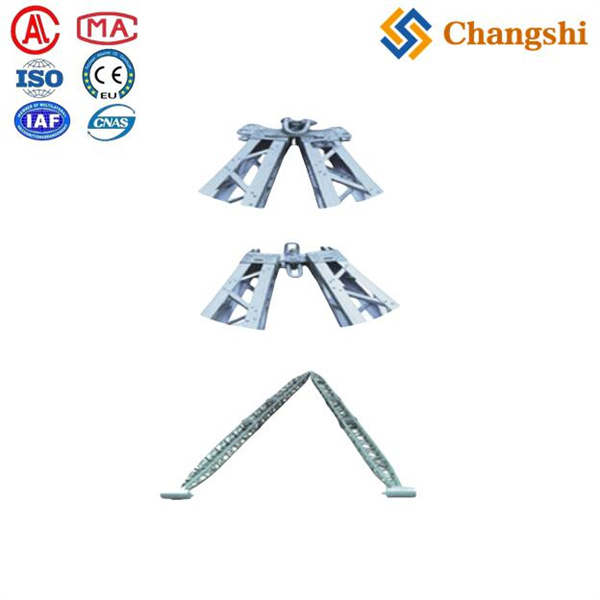

Designs:

A-shape lattice-like: Provides good stability.

Tubular A-shape: Simpler design for moderate loads.

Tubular tripod: For freestanding stability.

Inner-suspended: Designed to be lifted up inside a tower structure.

Tower-mounted small tubular: Smaller versions mounted directly onto towers.

Rating: Rated by allowable vertical load (kN) and maximum length (m).

Accessories: Roosterheads (sheave assemblies for load lines), heel blocks (at the base), guy wires, tag lines, and winches.

Derrick Cranes (Specifically Digger Derricks for Utility Work):

While the term "derrick crane" can refer to various fixed lifting machines (like those seen on ships or large construction sites, as described by BQ Cranes or Gohigher Construction), in the context of power utility and pole/tower work, the most common type of "derrick" is the digger derrick.

A digger derrick is a multi-purpose piece of heavy equipment typically mounted on a truck chassis. It combines the functions of:

A Digger/Auger: For drilling precise holes for utility poles.

A Derrick/Crane: A powerful hydraulic boom for lifting and positioning heavy objects.

A Winch: For hoisting and lowering loads.

How Digger Derricks are Used in Power Utility:

Pole Setting and Removal: This is their primary and most common application. The auger drills the hole, and then the boom lifts and accurately sets the pole into the hole. They are equally adept at safely removing old or damaged poles.

Transformer and Equipment Setting: Lifting and positioning heavy transformers, reclosers, switches, and other line equipment onto poles.

Material Handling: Moving and positioning coils of wire, crossarms, and other construction materials at the job site.

Light Tower Erection: Can be used for smaller tower sections where their reach is sufficient.

Versatility: Their ability to combine digging, lifting, and winching significantly improves efficiency and reduces the need for multiple pieces of equipment on a job site.

Mobility: Being truck-mounted, they offer excellent mobility between job sites.

Key Features of Digger Derricks:

Boom: Multi-section hydraulic boom, often with an insulated upper section for working near energized lines (though strict minimum approach distances still apply).

Auger: Integrated drilling auger, interchangeable for various hole sizes and soil conditions.

Winch: Powerful hydraulic winch for lifting.

Outriggers: Hydraulic outriggers for stability during lifting and digging operations.

Controls: Joystick controls for precise manipulation.

Ratings: Rated by lifting capacity (at various reaches), digging depth, and torque.

Distinction and Overlap:

Gin poles are simpler, often manual or winch-assisted, and best for incremental lifting of tall structures (like section-by-section tower erection) in remote or height-constrained environments where large cranes aren't feasible. They are temporarily affixed to the structure being built.

Digger derricks are vehicle-mounted, highly mobile, and integrate digging and lifting for pole installation and general heavy lifting on distribution and smaller transmission projects. They are a self-contained unit.

There's a subtle overlap in the "derrick" term, as some fixed derricks (like stiffleg derricks) could theoretically be used for specialized utility construction, but the "digger derrick" is the workhorse of the utility industry.