Digital Dynamometers for Line Tension

Digital dynamometers, often referred to as electronic load cells or digital force gauges, are highly accurate and versatile tools used for measuring tension in power lines, guy wires, pulling ropes, and various other rigging applications. In the context of line tension, they are preferred over traditional hydraulic dynamometers due to their precision, data logging capabilities, and advanced features.

Key Characteristics of Digital Dynamometers for Line Tension:

High Accuracy and Precision:

Utilize sophisticated strain gauge technology to convert mechanical force into a highly accurate electrical signal.

Typically offer accuracy of

pm0.1 to

pm0.5 of full scale, making them suitable for critical tensioning applications.

Digital Display:

Clear, easy-to-read LCD or LED displays, often backlit for use in low-light conditions.

Can display readings in various units (kN, kg, lbs, tons, daN).

Advanced Features:

Peak Hold: Captures and displays the maximum force applied during an operation.

Tare Function: Allows the operator to zero out the weight of rigging components.

Overload Alarms: Audible and/or visual alarms trigger if a preset load limit is exceeded, enhancing safety.

Units Conversion: Easily switch between different measurement units.

Battery Life Indicator: Essential for field use.

Rugged Enclosures: Designed with robust, weather-resistant (often IP rated) casings to withstand harsh outdoor conditions and industrial environments.

Data Logging and Connectivity:

This is a major advantage over hydraulic dynamometers.

Internal Memory: Many models can store a large number of tension readings.

Connectivity: Often equipped with USB, Bluetooth, or Wi-Fi connectivity for:

Data Transfer: Downloading logged data to a computer or mobile device for analysis, reporting, and record-keeping.

Real-time Monitoring: Transmitting live tension data to a remote display, a control room, or a tablet/smartphone app. This is crucial for precise stringing operations where constant feedback is needed.

Integration: Can be integrated into larger stringing machine control systems or SCADA (Supervisory Control and Data Acquisition) systems.

Types/Form Factors:

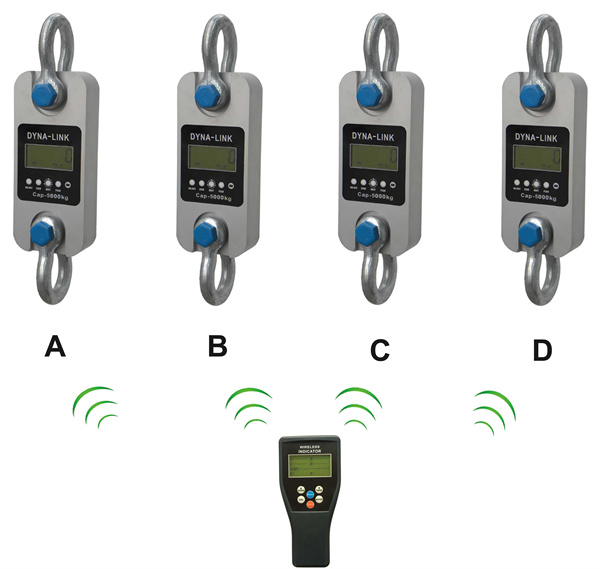

Inline (Shackle/Link-Type) Dynamometers: The most common for line tension. They are designed to be inserted directly in series with the pulling line, shackle, or conductor. Examples include "Loadlink Plus" or "Radiolink Plus" from Crosby|Straightpoint.

Running Line Tensiometers (RLT): Multi-sheave systems that continuously measure tension as a wire or rope passes through them. Often used with a remote digital display and capable of measuring speed and length as well. These are for dynamic measurements during continuous pulling.

Applications in Power Line Work:

Conductor Stringing: Directly measuring and monitoring pulling tension during the installation of new overhead conductors to ensure sag and tension specifications are met.

Sag and Tensioning: Precisely adjusting the tension of conductors after stringing to achieve the specified sag.

Guy Wire Tensioning: Measuring tension in guy wires for poles and towers to ensure structural stability.

Proof-Testing: Verifying the strength of rigging equipment, slings, and anchors.

Overhead Ground Wire (OHGW) / OPGW Installation: Monitoring tension during the stringing of ground wires that protect power lines from lightning.

Underground Cable Pulling: Monitoring tension to prevent damage to expensive underground cables as they are pulled through conduits.

Maintenance & Inspection: Periodically checking tension on existing lines to identify issues or verify parameters.