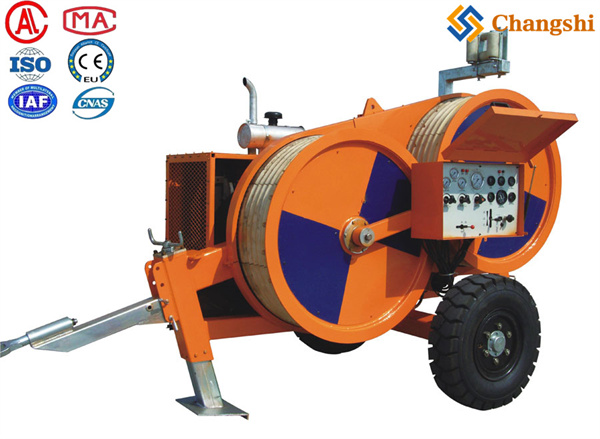

Puller-Tensioner Combination Units

Puller-tensioner combination units are incredibly versatile and efficient machines used in the construction and maintenance of overhead power transmission lines, distribution lines, and telecommunication cables (including fiber optics).

Why Combination Units Are Essential:

The ability to switch between pulling and tensioning offers significant advantages:

-

Versatility and Efficiency:

-

Reconductoring: This is a primary application. An old conductor needs to be pulled out while a new one is simultaneously tensioned in.

A single machine can handle both tasks, reducing the number of machines required on a job site, simplifying logistics, and saving time and cost. -

New Line Stringing: While dedicated pullers and tensioners are often used for very long and heavy new EHV/UHV lines, combination units can still be valuable for shorter sections, complex terrains, or smaller capacity new lines.

-

Pilot Rope Installation: They can pull in pilot ropes.

-

Groundwire and OPGW Stringing: Effective for installing optical ground wire (OPGW) or other ground wires.

-

-

Space and Cost Savings: Having one machine for two functions reduces the overall equipment footprint on a job site and lowers capital investment for contractors and utility companies.

-

Simplified Operation: Modern combination units often feature integrated control systems, allowing operators to easily switch modes and precisely manage both tension and pulling force from a single console.

How They Work (Dual Functionality):

The core hydraulic system is designed to provide force in two directions or modes:

-

Pulling Mode: The bullwheels or drums are driven to wind the pulling rope (or old conductor onto a scrap reel), generating the necessary pulling force.

The hydraulic system allows for variable speed and precise control of the pulling tension, often with an overpull protection system that automatically slows or stops if the tension limit is exceeded. -

Tensioning Mode: The machine applies a controlled braking force to the conductor as it's paid out from the reel. This keeps the conductor elevated and prevents it from touching the ground, protecting it from damage and minimizing safety hazards. Modern units often have automatic tensioning systems (ATS) that maintain a pre-set tension level, even with variations in line speed or terrain.

Key Features of Puller-Tensioner Combination Units:

-

Bullwheel Design: Most combination units feature bullwheels (often with multi-grooves and replaceable wear-resistant linings like MC nylon or elastomer segments) rather than just drums.

Bullwheels provide a continuous, high-friction grip on the conductor or rope without damaging it, and allow for efficient pulling and tensioning over long distances. V-groove bullwheels are common for accommodating splicing sleeves. -

Self-Loading Reel Winders: Many advanced units come with integrated, self-loading reel winders.

This is a significant advantage as it allows for the loading and unloading of conductor or pulling rope reels without needing an external crane, further increasing efficiency on site. -

Hydraulic System: Fully hydrostatic drive systems with closed-loop controls are standard.

These provide: -

Infinitely variable speed and line pull/tension control.

-

Overpull/overtension protection.

-

Hydraulic oil cooling systems for sustained operation.

-

Negative self-acting hydraulic brakes for immediate and secure stopping in both modes.

-

-

Operator Interface: Centralized control consoles, often with digital displays, provide real-time data (pulling force, tension, speed, distance) and allow for precise control. Radio remote controls are also common for enhanced safety and flexibility.

-

Mobility: Typically mounted on tandem-axle trailers with hydraulic jacks for stability during operation.

-

Engine: Powered by robust diesel engines (e.g., Cummins, Hatz) appropriate for the machine's pulling/tensioning capacity.

Applications:

-

Reconductoring Operations: The most common and ideal application, as described above. This is where their dual functionality truly shines.

-

New Conductor Stringing (especially for distribution and medium-voltage lines): Can be used for stringing new conductors where a dedicated tensioner and puller might be overkill or less logistically convenient.

-

OPGW and ADSS Cable Installation: Tensioning and pulling these delicate fiber optic cables safely.

-

Underground Cable Pulling: Some models are adapted with specialized drums and levelwind systems for pulling cables through conduits and ducts.

-

Pilot Rope Installation: Used to pull in the initial pilot ropes that will then be used to pull the heavier conductors.