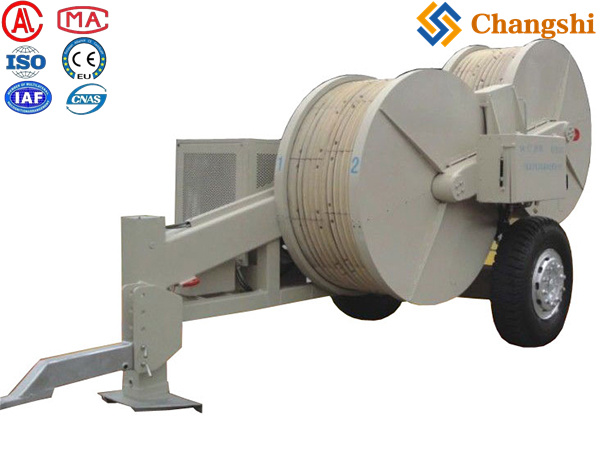

Tension Stringing Equipment

Tension stringing equipment is specialized machinery and tools used to pull, tension, and install conductors on overhead power transmission lines, ensuring proper sag, alignment, and safe handling during construction.

-

: Predominantly used for transmission lines, these tensioners have large bullwheels lined with materials that protect the conductor surface. They provide smooth, controlled tension to avoid conductor damage or birdcaging. There are two main types:

-

Multigroove tensioners with two bullwheels having multiple grooves each.

-

V-groove tensioners with one or more bullwheels having a single V-groove, though these require caution with multilayer conductors due to higher risk of damage.

-

-

: Usually employed for distribution lines with lower tension requirements (less than 5 kN). These tensioners brake the conductor reel to maintain tension during stringing.

-

: Machines that can both pull the pulling rope and tension the conductor. They often feature larger bullwheels than pullers alone and grooves lined with protective materials to prevent conductor surface damage. They can have independently controlled bullwheels for each conductor, facilitating simultaneous tensioning of multiple subconductors in bundle conductors.

-

: Used to guide conductors and ropes over towers and obstacles, reducing friction and enabling smooth conductor movement.

-

: Grips securely hold conductors during pulling, while swivels eliminate torque forces on conductors during stringing.

-

The tensioning system must provide constant tension at all stringing speeds and maintain tension even when the pull is stopped to avoid jerking or bouncing, which can cause conductor damage or equipment overload.

-

Bullwheel grooves must be lined with materials that prevent conductor surface damage and allow proper seating of the conductor wires, especially important for multi-layered conductors to avoid slippage or birdcaging.

-

For bundle conductors, tensioners with independently controlled bullwheels are preferred to regulate tension on each subconductor accurately.