Hydraulic Conductor Pullers

Hydraulic conductor pullers are specialized heavy machinery used primarily in the construction and maintenance of overhead and underground power transmission lines, as well as for telecommunication and fiber optic cable installations. They are designed to pull pilot ropes and conductors (electrical cables) with controlled, high-force tension.

Here's a breakdown of how they work, their applications, and other relevant information:

How Hydraulic Conductor Pullers Work

The core principle behind hydraulic conductor pullers is the use of hydraulic pressure to generate immense pulling force with precise control.

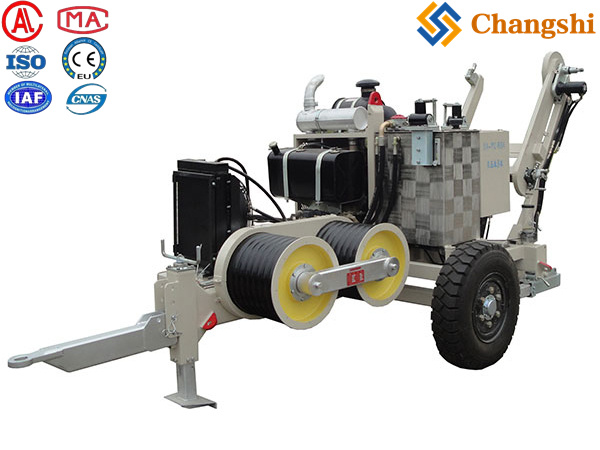

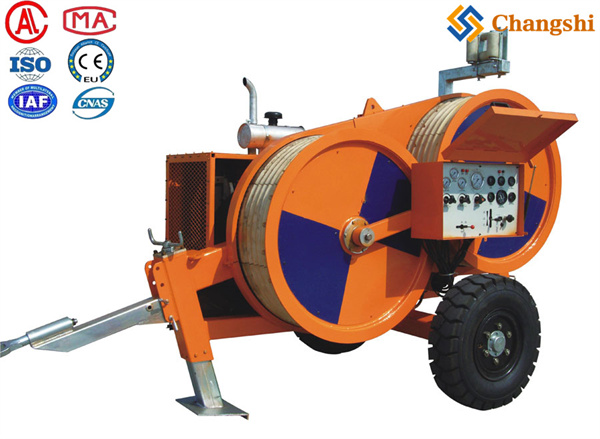

Hydraulic System: They feature a closed hydraulic circuit, typically powered by a diesel engine. This system includes an oil pressure cylinder, a pump, and bullwheels or capstans.

Force Generation: The pump creates oil pressure, which is then transmitted through fluid into the cylinder. This pressure extends the cylinder, producing a strong and controlled pulling force.

Bullwheels/Capstans: The pulling rope or conductor is wrapped around grooved bullwheels or capstans. These are typically made of wear-resistant materials like MC nylon lining segments or heat-treated steel, ensuring a high coefficient of friction without damaging the conductor.

Controlled Pulling: Advanced hydraulic systems allow for infinitely variable pull/tension control and speed control. Many modern pullers are equipped with digital interfaces, pressure gauges, and pull control devices that enable operators to monitor and preset the maximum pulling force. This is crucial for safety and to prevent damage to the conductor or related infrastructure. If the pre-set tension is reached, the machine can automatically slow down or stop the pulling operation.

Reel Winders: Many hydraulic pullers also have integrated reel winders for pilot ropes, which ensure proper counter-pull and safe operations.

Common Applications

Hydraulic conductor pullers are essential for:

Overhead Power Line Construction: Pulling pilot wire ropes for stringing operations, installing new power lines, and replacing existing ones. They are used for high-voltage transmission lines, medium-voltage distribution lines, and fiber optic lines (OPGW - Optical Ground Wire).

Underground Cable Installation: Laying power cables, fiber optic cables, and other telecommunication cables in ducts and trenches, especially in urban areas with extensive underground infrastructure.

Reconductoring Projects: Replacing old conductors with new ones on existing power lines, often requiring precise control to maintain tension.

Various Cable Types: Capable of handling a wide range of conductor diameters and types, including single, bundled, and even HTLS (High-Temperature Low-Sag) conductors.

Key Features and Advantages

High Pulling Capacity: They can generate significant pulling forces, ranging from a few kilonewtons (kN) to hundreds of kilonewtons, suitable for heavy-duty applications.

Precision Control: Hydraulic systems offer smooth, infinitely variable control over pulling force and speed, preventing conductor damage.

Safety Features: Equipped with overload protection, automatic stop mechanisms, tension limit and pull pre-setting systems, and pressure relief valves to ensure operator safety and protect equipment and conductors.

Versatility: Many models can function as both pullers and tensioners (puller-tensioners), offering dual functionality. They can also be adapted for different component sizes and shapes by changing jaws or arms.

Mobility: Available in various configurations, including trailer-mounted and truck-mounted units, for easy transport to job sites. Some are even designed for modular assembly in difficult-to-access areas or for helicopter transport.