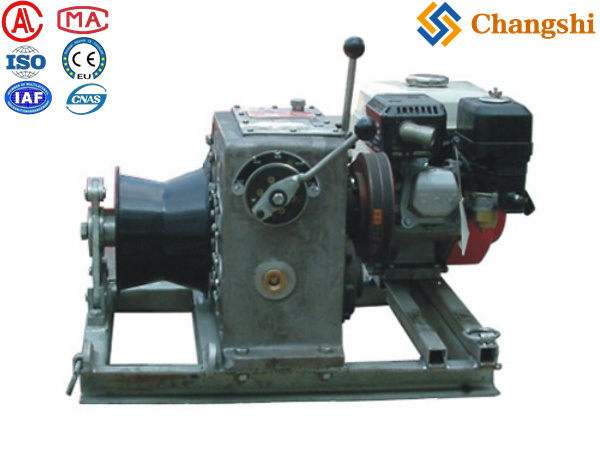

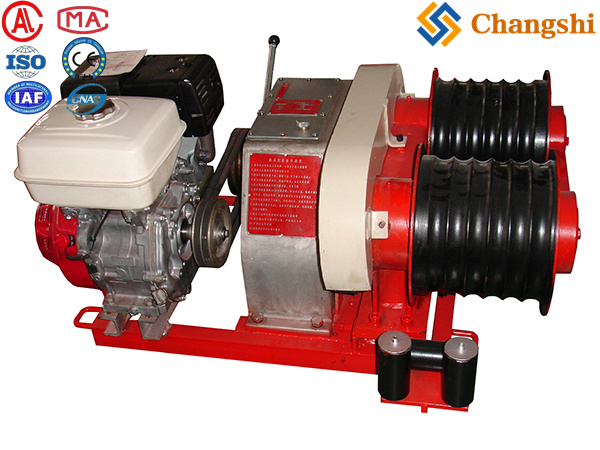

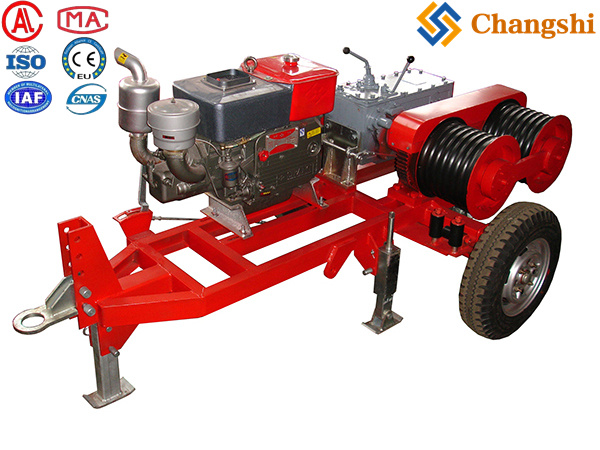

Diesel Powered Pullers

Diesel-powered pullers are the workhorses of the power transmission and distribution industry. The vast majority of high-capacity hydraulic pullers, puller-tensioners, and multi-drum pullers used for overhead line stringing and underground cable installation are powered by diesel engines.

Why Diesel Power?

The choice of diesel engines as the primary power source for these heavy machines is driven by several critical factors:

High Power and Torque: Diesel engines are renowned for their high torque output and robust power generation, which is essential for driving the powerful hydraulic pumps required to generate immense pulling forces (from several tons to over 40 tons). They can sustain high loads over long periods, crucial for long-distance cable pulls.

Fuel Efficiency (for their power output): Compared to gasoline engines of equivalent power, modern diesel engines are generally more fuel-efficient, leading to lower operating costs over the lifespan of the machine, especially given the continuous operation during stringing projects.

Durability and Reliability: Diesel engines are built for heavy-duty, continuous operation in demanding environments (construction sites, remote locations, varying weather conditions). They are known for their longevity and reliability, which is vital for minimizing downtime on critical infrastructure projects.

On-Site Fuel Availability: Diesel fuel is readily available at most construction sites and can be easily transported to remote locations, unlike the infrastructure required for electric power or specialized fuels.

Autonomous Operation: Diesel power provides complete autonomy, allowing the puller to operate independently of any external power grid. This is particularly important for transmission line projects that often span vast, undeveloped, or remote areas without access to electrical power.

Proven Technology: Diesel engines have been the standard for heavy construction and industrial machinery for decades, meaning there is a mature ecosystem for maintenance, spare parts, and skilled technicians.

Key Components Driven by Diesel:

In a diesel-powered hydraulic puller, the diesel engine is directly coupled to:

Hydraulic Pump: This is the heart of the system, converting the engine's mechanical power into hydraulic pressure, which then drives the bullwheels, drums, or other pulling mechanisms.

Ancillary Systems: The engine also powers generators for the machine's electrical systems (lights, controls, sensors), cooling fans for the hydraulic oil and engine, and other auxiliary functions.

Disadvantages of Diesel-Powered Pullers:

Despite their advantages, diesel-powered pullers also have drawbacks:

Emissions: Diesel engines produce exhaust emissions (NOx, PM, CO2), contributing to air pollution and greenhouse gas emissions. This is a growing concern, leading to stricter regulations and the development of alternative power sources.

Noise and Vibration: Diesel engines are inherently noisy and can produce significant vibrations, which can be challenging for operators and nearby communities.

Maintenance: While durable, they require regular maintenance (oil changes, filter replacements, fuel system checks) and can be more complex to maintain than electric systems.

Fuel Storage and Handling: Diesel fuel needs proper storage and handling to prevent spills and contamination.

Initial Cost: The engines themselves, especially those meeting modern emission standards, can add to the initial cost of the machine.

Hydraulic System Concerns: The hydraulic system itself, regardless of power source, can be prone to leaks and requires specialized fluid, and its efficiency can decrease due to heat loss.

Transitioning to Alternatives:

With increasing environmental concerns and technological advancements, there's a growing trend towards:

Electric/Battery-Electric Pullers ("Green Machines"): These offer zero emissions at the point of use, quieter operation, and potentially lower long-term running costs (if electricity is cheaper than diesel). However, they require access to charging infrastructure or onboard generators, which can limit their autonomy in remote locations. TSE International, for example, is a leader in this transition with their "Green Machine" series.

Hybrid Pullers: Combining a smaller diesel engine with an electric motor and battery bank, offering a balance of autonomy and reduced emissions/noise during certain operational modes.

However, for the foreseeable future, diesel-powered hydraulic pullers will remain the dominant choice for high-capacity, heavy-duty applications in transmission line and large cable installation due to their unmatched power, autonomy, and robustness.