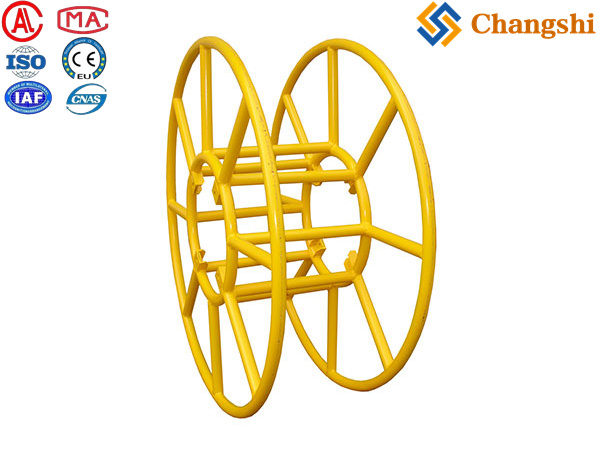

Collapsible & Portable Reel Stands

Collapsible and portable reel stands are crucial for situations where power line stringing or cable laying needs to be done in remote, difficult-to-access locations, or where equipment needs to be transported frequently. Their design prioritizes lightweight construction, ease of assembly/disassembly, and compact storage.

Unlike the heavy-duty, often vehicle-mounted or permanently installed reel stands, these portable versions focus on maneuverability and field deployment by smaller crews or in confined spaces.

Key Characteristics of Collapsible & Portable Reel Stands:

Lightweight Materials:

Primarily constructed from high-strength aluminum alloys. This significantly reduces the overall weight, making them easier to carry by hand or transport in smaller vehicles.

For lighter-duty applications, some might use robust tubular steel, but aluminum is preferred for true portability when weight capacity is still needed.

Collapsible/Foldable Design:

This is the defining feature. The stands are designed with hinges, quick-release pins, or telescoping legs that allow them to fold flat or break down into smaller, manageable components.

This minimizes their footprint for storage in utility trucks, vans, or even ATV/UTV trailers, and makes them easier to carry to remote job sites.

Ease of Assembly/Disassembly:

Designed for quick and tool-free (or minimal tool) setup and breakdown in the field. This saves valuable time on the job.

Capacity Range:

While "heavy-duty" hydraulic stands can handle 10-20 tons, portable stands typically support lighter to medium-sized cable reels. Common capacities range from:

Light-Duty: 200 lbs to 1,000 lbs (for smaller communication cables, fiber optic, or lighter distribution wires).

Medium-Duty: 1,000 lbs to 5,000 lbs (for larger distribution cables, some overhead ground wires, or smaller transmission conductors).

They are still designed to accommodate a range of reel diameters and widths, often specified in their product details.

Lifting Mechanism:

Manual Screw Jacks: Common for medium-duty portable stands, offering controlled lifting with a crank.

Pin & Hole Adjustment: For very light-duty "reel bucks" or caddies, the spindle height might be adjusted by inserting pins into pre-drilled holes.

Simplified Hydraulic Jacks: Some heavier-end portable models might incorporate smaller, integrated hydraulic jacks for easier lifting of reels up to a few tons.

Basic Braking (if any):

For lighter models, braking might be minimal or non-existent (relying on hand-tensioning).

For medium-duty models, a simple mechanical disc brake (often friction-based with a hand-operated lever) is common to prevent over-spinning. Full hydraulic braking systems are generally reserved for the fixed, heavier-duty stands.

Common Types & Applications:

Cable Caddies / Reel Bucks: These are the simplest, often low-profile, and very portable frames that support a reel for payout. Often foldable or collapsible. (e.g., Jameson Portable Reel Buck, Lemco Collapsible Cable Caddy mentioned in search results). Ideal for smaller spools of wire (Romex, multi-conductor control cables, fiber optic).

Foldable Tripod Stands: Some designs resemble tripod stands, offering stability and portability for lighter reels.

Modular Reel Stands: Designed with interchangeable components that can be quickly assembled or disassembled, making them highly customizable and easy to transport.

Field Repair/Maintenance: Often used for quick cable deployment or retrieval during maintenance or repair work where a full stringing setup isn't practical.

Underground Cable Laying: For smaller lengths of cable or pilot ropes in trenches where space is limited.