Conductor Carts & Trolleys

Conductor carts and trolleys are specialized pieces of equipment used in power line construction and maintenance, particularly for overhead lines. They provide a safe and efficient way for workers to traverse long spans of conductors, often at height, to perform tasks such as installing spacers, dampers, or other accessories, or for detailed inspection.

What are Conductor Carts & Trolleys?

Unlike the stringing blocks/rollers that simply allow the conductor to pass through during initial installation, conductor carts and trolleys are designed to ride on the conductors themselves. They allow personnel and sometimes light equipment to be moved along the energized or de-energized lines.

Terminology Clarification:

"Conductor carts" and "conductor trolleys" are often used interchangeably.

"Overhead Line Bicycles" or "Inspection Bicycles" are also common terms, particularly for single-conductor versions, as they can resemble bicycles.

"Spacer trolleys" specifically refer to those used for installing spacers on bundled conductors.

Types and Uses:

Inspection Trolleys / Overhead Line Bicycles (Single Conductor):

Purpose: Primarily for inspection of single overhead conductors, identifying damage, corrosion, or assessing overall line condition. They can also be used for installing lightweight accessories.

Design: Typically a lightweight frame with wheels that ride on the conductor. Many resemble bicycles, with pedals for propulsion (hence "bicycles"). Some might be motorized (electric).

Features: Often designed for one person, with safety harnesses to secure the operator. They might have small platforms for tools.

Application: Useful for routine patrols and detailed visual inspections where vehicle access below the line is difficult or impossible.

Examples: Tesmec CRS/CRM series, Dongfang SFD1A/SFD3 series.

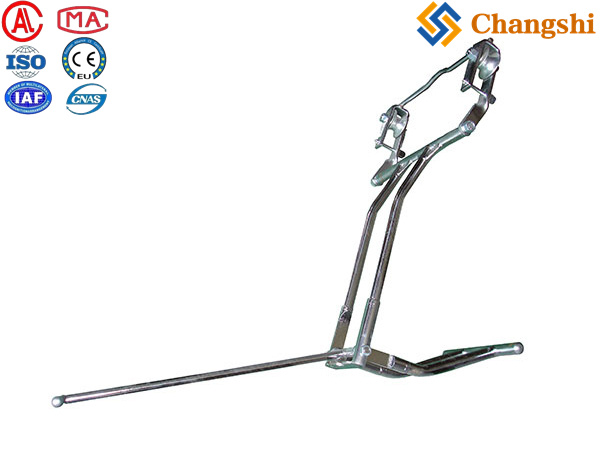

Spacer Trolleys / Conductor Carts (for Bundled Conductors):

Purpose: Crucial for the installation and maintenance of spacers on bundled conductors. Bundled conductors (2, 3, 4, or even 6 conductors per phase) require spacers at regular intervals to maintain their geometry and prevent clashing. These trolleys allow workers to ride the bundle and install/repair spacers. They can also be used for inspection of bundled lines.

Design: More robust than single-conductor versions, designed to accommodate multiple conductors simultaneously. They often have a platform for one or two workers and their tools. Some are purely manual, while others are motorized (electric or small internal combustion engine) for easier movement over long spans.

Features:

Wheels or rollers specifically designed to fit and ride on each conductor within the bundle.

Safety features like handrails, secure attachment points for harnesses, and braking systems.

Payload capacity for workers and tools.

Adjustable to different bundle configurations (e.g., 2-bundle, 3-bundle, 4-bundle, 6-bundle) and distances between sub-conductors.

Application: Essential for high-voltage transmission lines which commonly use bundled conductors.

Examples: Tesmec CRB/CRT series, Dongfang SFS/FCS series (for 2, 3, 4, or 6 bundle conductors).

Specialized Maintenance/Repair Carts:

Purpose: Some larger, more robust carts might be designed for specific heavy maintenance tasks, carrying more tools or specialized equipment.

Features: May have power take-offs, integrated winches, or larger platforms.

Key Considerations and Features:

Safety: Paramount. All carts/trolleys must have robust braking systems, secure attachment points for fall protection harnesses, and clear operating procedures.

Conductor Type & Diameter: The wheels/rollers must be compatible with the conductor material (e.g., ACSR, AAAC) and its diameter to prevent damage.

Bundle Configuration: For bundled conductor carts, the ability to adjust to the specific number of conductors and their spacing is vital.

Propulsion: Manual (pedals, hand-crank) for shorter distances or lighter work; motorized (electric, gasoline engine) for longer spans, heavier loads, or efficiency.

Material: Often aluminum alloy for lightweight strength and corrosion resistance.

Weight & Portability: Easy to transport and install on the line.

Ergonomics & Comfort: Especially for long hours of use.

Standards: Should meet relevant industry safety and performance standards.