Hydraulic Compression Tools for Splicing Wire & Cable

Hydraulic compression tools are indispensable for creating robust, durable, and electrically secure splices and terminations in wire and cable, particularly for medium and high-voltage power applications. They utilize hydraulic pressure to exert immense force, ensuring a permanent, high-quality connection.

How Hydraulic Compression Tools Work:

The fundamental principle is based on hydraulics:

Fluid Pressure: A small amount of force applied to a piston in a master cylinder (often via a hand pump, foot pump, or battery-powered pump) is amplified through hydraulic fluid.

Force Transfer: This pressurized fluid is then transferred to a larger piston in the tool's crimping head.

Die Compression: The large piston moves, forcing a set of precisely machined dies to close around the connector (e.g., a splice sleeve, terminal lug) and the conductor.

Deformation: The dies compress the metallic connector, deforming it (and the conductor strands inside it) into a solid, homogeneous mass. This creates a strong mechanical bond and a low-resistance electrical connection.

Release: A release valve or mechanism allows the hydraulic pressure to be relieved, and the dies open, allowing the crimped connection to be removed.

Advantages of Hydraulic Compression Tools:

High Force Output: Can exert much greater force than manual mechanical crimpers, making them suitable for larger conductors and heavier-duty applications.

Consistent Crimp Quality: Provides uniform and repeatable crimps, critical for ensuring reliable electrical connections and preventing hot spots.

Reduced User Effort: Requires significantly less physical effort from the operator compared to mechanical tools, especially for large conductors, reducing fatigue and improving productivity.

Precision and Control: Offers better control over the crimping process.

Versatility: With interchangeable dies, a single tool can be used for a wide range of conductor sizes and connector types.

Types of Dies Used:

The dies are crucial for the quality of the crimp and must perfectly match the connector and conductor size. They typically come in different shapes:

Hexagonal Dies: Most common for power cables (lugs, splices, tap connectors). They form a hexagonal crimp around the connector, creating a strong, secure, and electrically sound connection by compressing the conductor strands into a solid, homogeneous mass within the connector.

Round Dies: Used for certain types of compression fittings, often for wire rope or specific types of electrical connections where a full circumferential compression is desired.

"W" Type Dies, "U" Type Dies, "H" Tap Dies, "C" Tap Dies: These are specific industry-standard die types, often color-coded by manufacturers (like Burndy's Color-Keyed® system or Nicopress's indexing system) to ensure the correct die is used for a specific conductor and connector combination. The color or number on the die corresponds to the color/number on the connector itself.

Custom Dies: For highly specialized connectors or applications.

Dies are made from hardened steel to withstand the immense compression forces.

Applications:

Splicing Conductors: Joining two sections of overhead or underground cable with compression splice sleeves.

Terminating Conductors: Attaching terminal lugs (connectors) to the ends of cables for connection to equipment, busbars, or transformers.

Tapping Conductors: Creating branch connections from a main conductor using tap connectors (e.g., H-taps, C-taps).

Grounding Connections: Crimping connectors for grounding applications.

Installing Dead-End Fittings: Compression-type dead-end clamps are often installed with hydraulic tools.

Types of Hydraulic Compression Tools:

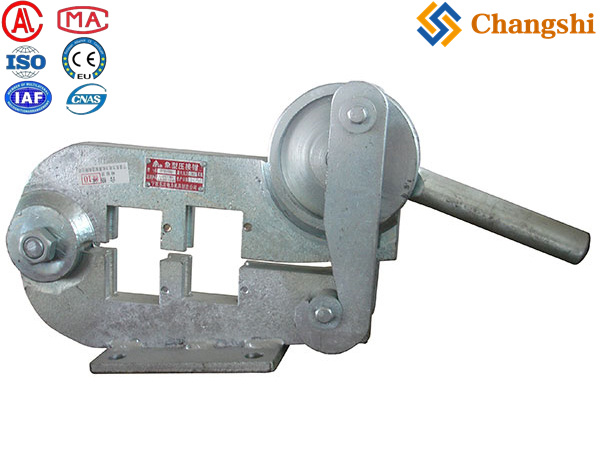

Hand-Operated Hydraulic Tools: Integrated pump and crimping head. Portable and suitable for field use for smaller to medium-sized conductors (e.g., up to 400-500 kcmil).

Remote Head Hydraulic Tools: The crimping head is separate from the hydraulic pump. The head is lighter and more maneuverable for tight spaces, while the pump (manual or powered) remains on the ground or a work platform. Ideal for larger conductors or in constrained environments.

Battery-Powered Hydraulic Tools: Incorporate a battery-driven pump directly into the tool, offering the convenience of a hand tool with the power of hydraulics. Increasingly popular for speed and portability.

Foot-Operated Hydraulic Pumps: Free up the user's hands for positioning the work.

Large Tonnage Hydraulic Presses: For very large conductors or specialized applications, these are workshop-based units capable of extremely high forces.