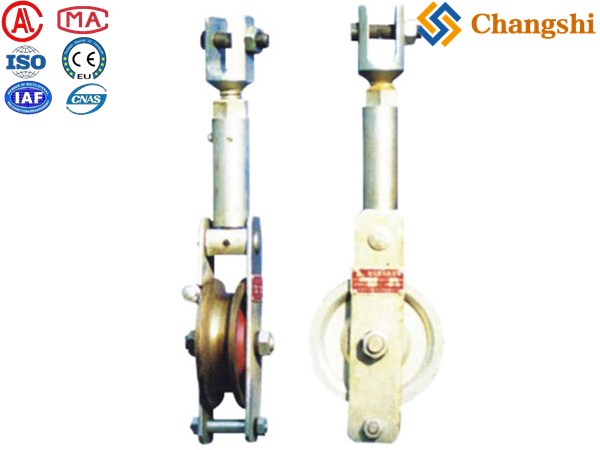

Ground Wire Stringing Blocks

Ground wire, also commonly referred to as shield wire or overhead ground wire (OHGW), is a crucial component of overhead power transmission lines. It's typically strung at the very top of transmission towers, above the phase conductors. Its primary purpose is to protect the phase conductors from lightning strikes by intercepting the lightning and safely directing the current to the ground.

While OPGW (Optical Ground Wire) is a type of ground wire that also contains fiber optics, a "ground wire" in the traditional sense refers to a purely metallic conductor, usually made of galvanized steel or aluminum-clad steel (ACS).

Ground Wire Stringing Blocks:

Stringing blocks for traditional ground wire share many characteristics with those used for phase conductors, but with some specific considerations:

Single Sheave Design: Ground wire is almost always a single conductor (not bundled), so single-sheave stringing blocks are used.

Sheave Material:

Aluminum Alloy: Very common for ground wire blocks. It's lightweight, strong, and offers good durability.

Urethane or Neoprene Lined Aluminum: While not always strictly necessary for a bare steel or ACS ground wire (as there's no delicate insulation or optical fiber to protect), these linings still reduce friction and prevent surface abrasion, extending the life of both the block and the ground wire. They are particularly beneficial if the ground wire is aluminum-clad steel, to prevent damage to the aluminum layer.

Nylon/MC Nylon: Less common for the primary ground wire, but might be used for lighter applications.

Sheave Diameter:

Generally Smaller than OPGW Blocks: Since traditional ground wire doesn't have internal optical fibers with strict bending radii, the sheaves don't need to be as excessively large as those for OPGW.

Still Large Enough for Bending Radius: However, they are still sized appropriately to minimize bending stress and friction for the specific ground wire diameter. Common diameters for ground wire blocks might range from 300mm (12 inches) to 800mm (31.5 inches), depending on the ground wire size and project specifications.

Robust Frame and Bearings: Ground wires are also strung under significant tension, so the blocks require strong frames (aluminum alloy or galvanized steel) and high-quality, sealed anti-friction bearings to handle the loads and ensure smooth operation.

Grounding Features (Optional but Important):

Some ground wire stringing blocks (and even phase conductor blocks, as seen in search results for "DDIN Grounded Stringing Blocks") can incorporate a grounding attachment or a grounding roller.

Purpose: This feature ensures that any induced voltage or static charge on the ground wire during stringing is safely dissipated to ground. It typically involves a direct electrical connection from the sheave (or a separate grounding roller in contact with the wire) to a ground stud on the block frame, which is then connected to a temporary ground rod or the tower's grounding system. This significantly enhances safety during stringing operations, especially near live lines.

Difference from OPGW Stringing Blocks:

While OPGW is a type of ground wire, its stringing block requirements are distinct from traditional, purely metallic ground wire:

Sheave Material: OPGW blocks strongly favor Nylon/MC Nylon or urethane/neoprene-lined aluminum to protect the delicate optical fibers. Traditional ground wire blocks can use plain aluminum without as much concern, though lining is still beneficial.

Sheave Diameter: OPGW blocks have an absolute requirement for very large diameters (e.g., minimum 660mm, often 800mm-1000mm+) to protect the fibers' bending radius. Traditional ground wire blocks, while still using adequate diameters, don't face this critical fiber bending constraint, so their diameters might be somewhat smaller for comparable metallic cable sizes.

Small Groove for Pilot Rope: Many OPGW blocks have a "double groove" or "small groove" feature for the pilot rope, which is less common (though not unheard of) in traditional ground wire blocks.