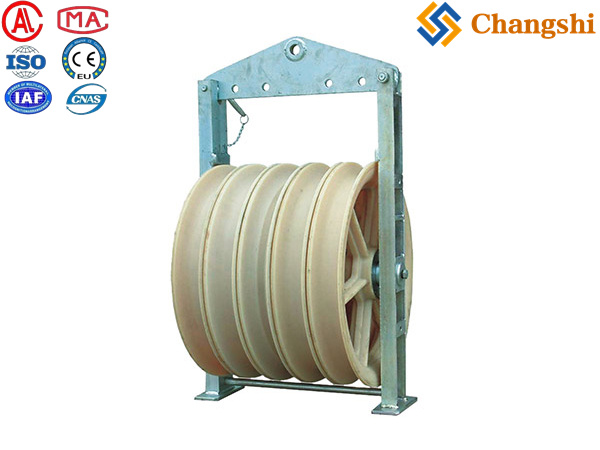

Large Diameter Conductor Stringing Blocks

Large diameter conductor stringing blocks are absolutely essential for the safe, efficient, and damage-free installation of modern high-voltage (HV), extra-high voltage (EHV), and ultra-high voltage (UHV) transmission lines. The "large diameter" aspect is a critical design consideration, directly impacting the integrity of the conductor.

Why Large Diameter is Crucial:

The primary reason for using large diameter sheaves in stringing blocks is to minimize the bending stress (and thus, bending fatigue and damage) on the conductor as it passes over the sheave.

Here's a breakdown of the importance:

Reduced Bending Stress on Conductors:

Conductor Fatigue: When a conductor bends around a sheave, its outer strands are stretched and compressed. The tighter the bend (i.e., the smaller the sheave diameter), the greater this stress. Repeated bending over small diameters can lead to metal fatigue in the strands, especially in the outer layers, causing them to crack or break prematurely.

Internal Damage: For complex conductors like ACSR (Aluminum Conductor Steel Reinforced), ACSS (Aluminum Conductor Steel Supported), or HTLS (High-Temperature Low-Sag) conductors, excessive bending can cause internal damage to strands or even the core, which isn't visible externally but compromises the conductor's strength and longevity.

Surface Damage: A larger radius of curvature reduces the contact pressure between the conductor and the sheave groove, minimizing abrasion and nicks on the conductor's surface.

Accommodation of Large Conductors:

EHV/UHV lines use very large diameter conductors, often bundled. Small sheaves simply cannot accommodate these physical dimensions without forcing severe bending. Large diameter blocks are physically necessary to cradle these massive conductors properly.

Smooth Passage of Splices and Connectors:

During stringing, compression splices, mid-span joints, or pulling rope connectors need to pass through the blocks. Larger sheave grooves and throat openings (often found on large diameter blocks) allow these bulkier sections to pass through more smoothly, reducing the risk of snagging or shock loading.

Lower Friction:

While high-quality bearings are the primary factor in reducing friction, a larger sheave diameter generally leads to less angular displacement per unit of linear travel, which can contribute to smoother running and slightly lower frictional losses, though the effect is less pronounced than bearing quality.

Accommodation of Sensitive Conductors:

For delicate conductors like OPGW (Optical Ground Wire) or ADSS (All-Dielectric Self-Supporting) fiber optic cables, which have optical fibers within, minimizing bending stress is absolutely critical to prevent signal loss or fiber breakage. Large diameter, often urethane-lined, sheaves are mandatory for these.

Typical Large Sheave Diameters:

"Large diameter" is relative to the conductor size. For EHV/UHV conductors, sheaves can range from:

500mm (20 inches) to 660mm (26 inches): Often considered large for single-conductor distribution or smaller transmission lines.

800mm (31.5 inches) to 1160mm (45.7 inches): Standard for single large-diameter transmission conductors (e.g., ACSR LGJ630, LGJ720, ACSR1250) or OPGW.

Up to 1500mm (59 inches), 1800mm (71 inches), or even 2400mm (94 inches) / 108 inches (2740 mm): For extremely large conductors, special HTLS conductors, or very high-tension bundle stringing.

Materials and Features for Large Diameter Blocks:

Sheave Material: Often high-strength aluminum alloy (polished or unpolished), frequently with urethane or neoprene lining to provide a protective, low-friction surface. MC Nylon or high-strength composite materials are also used.

Frame Material: Robust, often galvanized steel or heavy-duty aluminum alloy to handle the substantial loads.

Bearings: High-capacity, sealed, tapered roller bearings or large ball bearings are essential for smooth operation under heavy loads.

Load Capacity: These blocks have very high Working Load Limits (WLLs), often ranging from 30 kN to over 120 kN (3 to 12 metric tons), with significantly higher breaking loads.

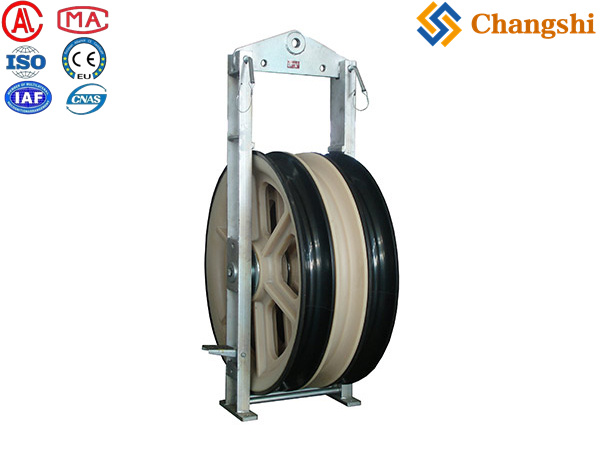

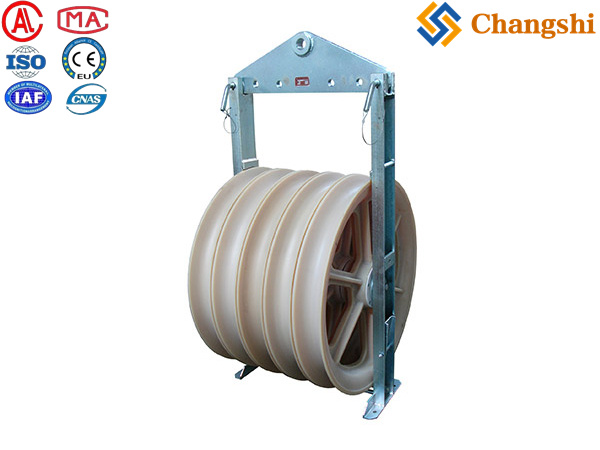

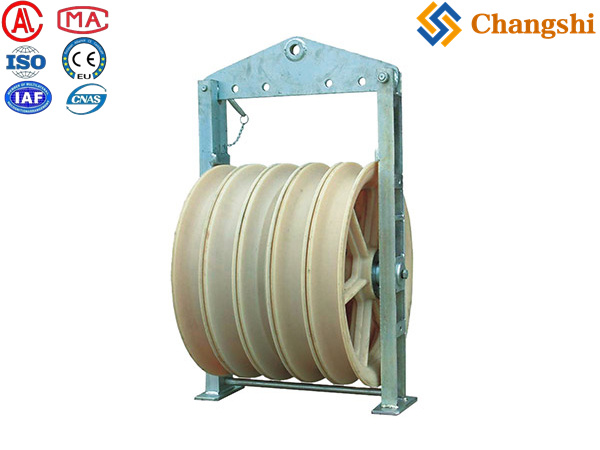

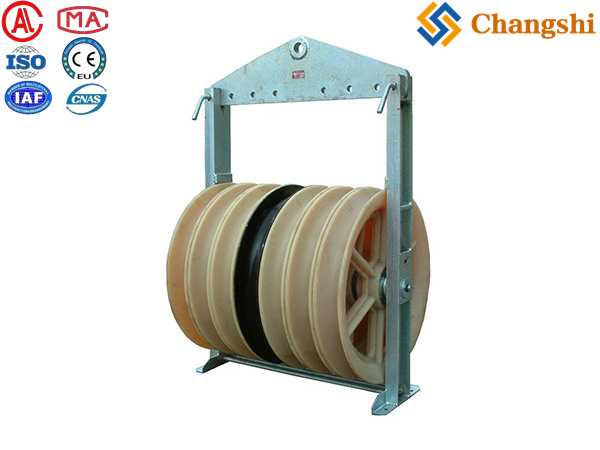

Bundle Configurations: Large diameter blocks are also available in multi-sheave configurations (e.g., 2, 3, or 4 sheaves) for bundled conductor stringing, where each sheave in the bundle block is of a large diameter.