Swivels & Connectors for Pulling Ropes

Swivels and connectors are relatively small but incredibly important components in power line stringing operations. They act as critical links between different parts of the pulling assembly (e.g., pulling rope, conductor pulling grip, pilot line, measuring devices) and play a vital role in ensuring safety, preventing damage to the conductor, and maintaining efficiency during the pull.

Swivels:

A swivel is a rotating device designed to prevent the build-up of torsional (twisting) forces in the pulling rope and conductor during a stringing operation. When a conductor is pulled from a large reel, it can inherently have some twist, or twisting forces can be generated due to friction, uneven tension, or the pulling path. If these twists are not relieved, they can:

Damage the pulling rope.

Damage the conductor itself (causing kinks or internal stress).

Lead to uneven sag.

Cause the pulling grip to unwind.

Key Features of Swivels:

Bearings: High-quality swivels use sealed thrust bearings (for tensile load) and radial bearings to allow smooth rotation even under heavy load.

Material: Typically made from high-tensile galvanized steel or stainless steel for strength and corrosion resistance.

Connection Ends: Common configurations include:

Clevis to Clevis: Two U-shaped ends with pins, allowing connection to other clevis-ended components.

Eye to Eye: Two closed loops.

Clevis to Eye: One clevis end and one eye end.

Bull-nose style: A streamlined, tapered end for smoother passage through stringing blocks, often matched with a compatible grip.

Rated Capacity (WLL/MBL): Swivels are rated by their Working Load Limit (WLL) or Minimum Breaking Load (MBL). It's crucial to select a swivel with a capacity that meets or exceeds the maximum pulling force of the tensioner/puller.

Breakaway Swivels (Mechanical Fuses): Some specialized swivels are designed with "shear pins" that break at a pre-set load. This acts as a mechanical fuse to protect expensive conductors or equipment from overload damage during a pull. They are typically used in underground pulling or for specific overhead applications where overload protection is paramount.

Applications in Stringing:

Placed between the conductor pulling grip (sock) and the pulling rope.

Used in complex pulling setups to isolate torque.

Connectors (for Pulling Ropes):

Connectors are used to securely link different sections of the pulling assembly, especially when connecting different types of ropes or a rope to a swivel/grip.

Common Types of Connectors for Pulling Ropes:

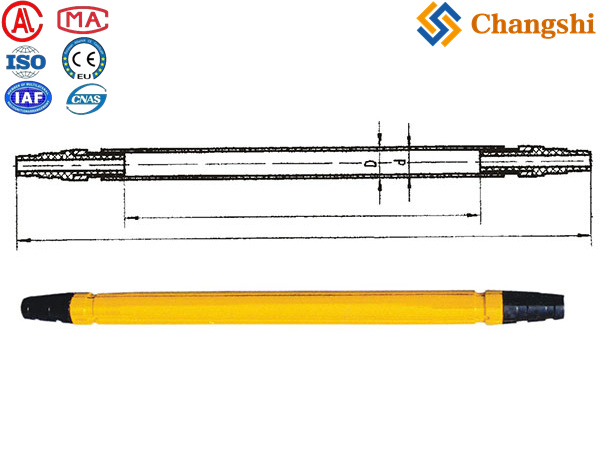

Rope to Swivel Connectors:

Purpose: Specifically designed to create a strong, low-profile connection between a pulling rope and a swivel (or directly to a pulling grip with an eye end).

Design: Often features a clevis or similar attachment point for the swivel/grip on one end, and a robust mechanism for securing the rope on the other (e.g., a roller system to prevent fraying, or a wedge-type grip).

Materials: High-strength steel.

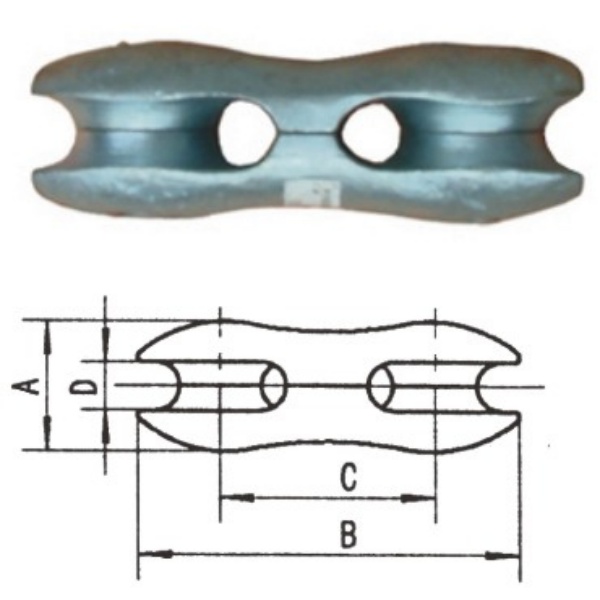

Rope to Rope Connectors:

Purpose: Used to join two pulling ropes together, for example, when extending a pull or transitioning between different rope types.

Design: Features two ends designed to grip and secure ropes, often with internal rollers or smooth channels to prevent rope damage.

Materials: High-strength steel.

"Can-Link" Connectors (Specialized):

Purpose: As described by DCD Design, these are used to connect two items with lug or wire loop fittings. A common use is to connect a wire mesh grip (which might have a small loop) to the pulling wire.

Design: Often made from high-strength stainless steel with hardened clevis pins, providing a compact and strong link.

Key Considerations for Connectors:

Strength Rating: Must match or exceed the breaking strength of the ropes they are joining.

Rope Compatibility: Designed for specific rope diameters and materials (e.g., synthetic ropes, wire rope).

Smoothness/Low Profile: Designed to pass smoothly through stringing blocks and conduits without snagging.

Ease of Use: Must allow for quick and secure attachment and detachment in the field.

Durability: Built to withstand the harsh conditions of power line work.