Running Boards for Multi-Conductor Stringing

Running boards, also sometimes called running sheaves, pulling heads, or running heads, are specialized devices used in the multi-conductor stringing process, particularly for bundled conductors (2, 3, 4, or more sub-conductors per phase). They are a critical link between the pulling rope (often a single anti-twist steel wire rope or a high-strength synthetic rope) and the multiple individual sub-conductors of a bundle.

What are Running Boards and How Do They Work?

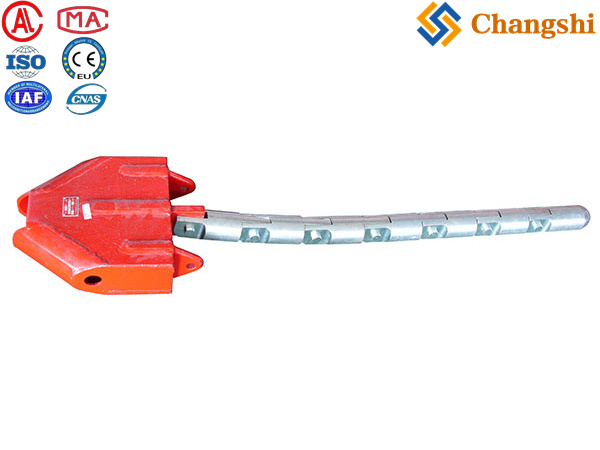

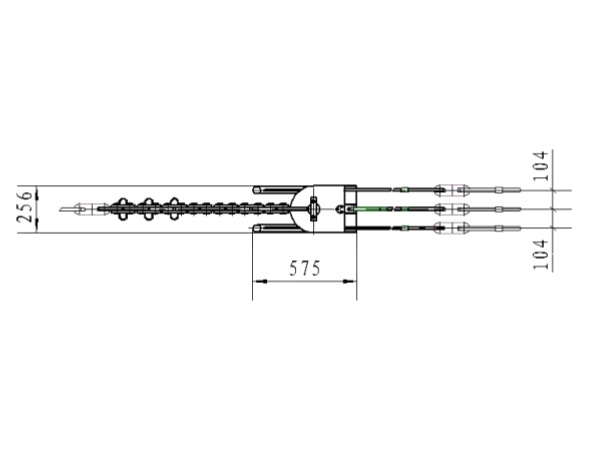

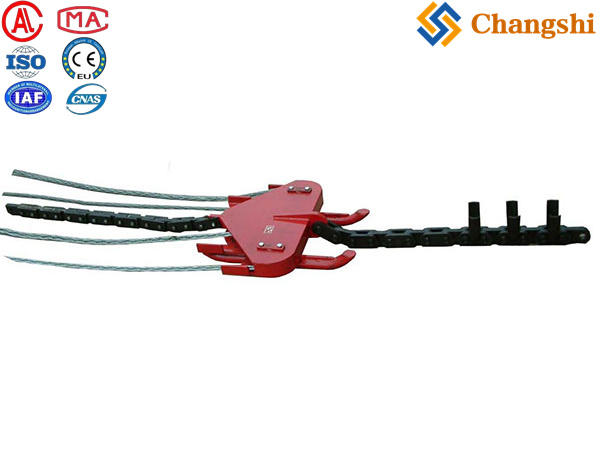

A running board is essentially a sturdy frame equipped with multiple, individually rotating sheaves or rollers. Each sheave is designed to guide one sub-conductor of the bundle.

Here's how they function:

Connecting the Pulling Rope to the Bundle:

The single pulling rope (which has passed through all the bundle stringing blocks) is attached to the central pulling eye of the running board.

Each individual sub-conductor of the bundle is then attached to one of the sheaves on the running board, typically using a dedicated conductor grip (like a mesh grip/cable sock or an automatic self-gripping clamp designed for multi-conductor attachment). This connection is made at the tensioner side of the stringing operation.

Maintaining Spacing and Preventing Twisting:

As the pulling rope pulls the running board, each sub-conductor, being attached to its own independent sheave on the board, can rotate and move slightly relative to the other sub-conductors.

This design prevents the individual sub-conductors from twisting around each other or becoming tangled as they are pulled. It helps maintain the designed geometric configuration of the bundle.

Smooth Passage Through Bundle Blocks:

The running board is designed to smoothly pass through the grooves of the multi-sheave bundle blocks on the towers. The individual sheaves on the running board align with the corresponding sheaves in the bundle blocks, ensuring a continuous and low-friction pull.

Many running boards feature a "flexible pendulum tail" or a counterweight/gator tail at the rear. This tail helps to keep the running board properly aligned and balanced as it enters and exits the stringing blocks, preventing it from flipping or snagging, especially during high-speed pulling or in challenging terrain.

Equalizing Tension (in some types):

There are generally two types of running boards:

Fixing Type: Each conductor attachment point is rigidly fixed to the frame.

Balance Type (or Balancing Head): Some running boards incorporate a "balance pulley structure" (as described by Dongfang/E-grid Power). This design uses a system of small pulleys or linkages within the running board itself to help equalize the tension on each individual sub-conductor as it's being pulled, ensuring that all conductors are stressed evenly. This is particularly useful when conductors are pulled from the same bull wheels of the tensioner.

Key Characteristics:

Number of Sheaves: Corresponds to the number of sub-conductors in the bundle (e.g., 2 sheaves for a 2-bundle, 3-4 sheaves for a 3-bundle, 4-5 sheaves for a 4-bundle, etc.).

High Strength: Constructed from robust materials (e.g., high-strength steel or aluminum alloy) to withstand the massive pulling forces involved in multi-conductor stringing (Working Loads often range from 80 KN to over 320 KN).

Durable Sheaves/Rollers: Made from hardened steel, aluminum, or sometimes with urethane or nylon liners to reduce friction and wear.

Large Diameter Sheaves (on the running board itself): While smaller than the tower-mounted stringing blocks, the sheaves on the running board are still sized to minimize bending stress on the individual conductors as they enter the board.

Weight: Designed to be as light as possible while maintaining strength, as they are part of the moving load.

Importance in Multi-Conductor Stringing:

Prevents Conductor Damage: By ensuring proper spacing and preventing twisting, running boards protect the individual sub-conductors from damage during the pull.

Efficient Stringing: Enables the simultaneous pulling of all sub-conductors of a bundle in a single operation, significantly speeding up installation.

Maintains Bundle Configuration: Helps ensure that the conductors retain their correct spatial relationship throughout the stringing process, which is critical for their final electrical performance.

Smooth Operation: Facilitates the smooth passage of the entire conductor bundle through the tower-mounted stringing blocks.