OPGW (Optical Ground Wire) & ADSS (All-Dielectric Self-Supporting) Stringing Blocks

OPGW (Optical Ground Wire) and ADSS (All-Dielectric Self-Supporting) cables are specialized fiber optic cables used in power transmission and distribution networks. Their unique construction and the extreme sensitivity of optical fibers demand equally specialized stringing blocks to ensure their integrity during installation.

Why OPGW & ADSS Require Specialized Stringing Blocks:

Both OPGW and ADSS cables are designed to carry high-speed data (fiber optics) while also serving a structural role (ground wire for OPGW, self-supporting for ADSS). The core challenge during installation is to prevent any damage to the delicate optical fibers, which can be easily compromised by excessive bending, crushing, or abrasion.

Here's why their stringing blocks are unique:

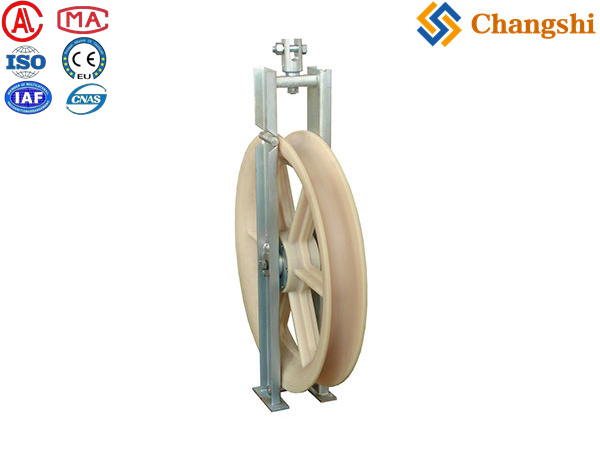

Large Sheave Diameter: This is paramount. Optical fibers have very strict bending radius limits. Bending them beyond this limit can cause micro-bends or macro-bends, leading to signal loss (attenuation) or even fiber breakage. Therefore, OPGW and ADSS stringing blocks feature very large diameter sheaves to ensure the cable experiences a gentle curve. Common diameters range from:

500mm (20 inches) to 800mm (31.5 inches) for most standard OPGW/ADSS.

Up to 1000mm (39 inches) or even larger for particularly sensitive or large-diameter OPGW/ADSS cables.

Specialized Sheave Materials/Linings:

MC Nylon / Polymer Composites: These are the most common materials. They are inherently non-conductive (important for ADSS, which is dielectric, and OPGW when working near live lines) and provide a smooth, low-friction, and non-abrasive surface that is gentle on the cable's jacket and internal fibers.

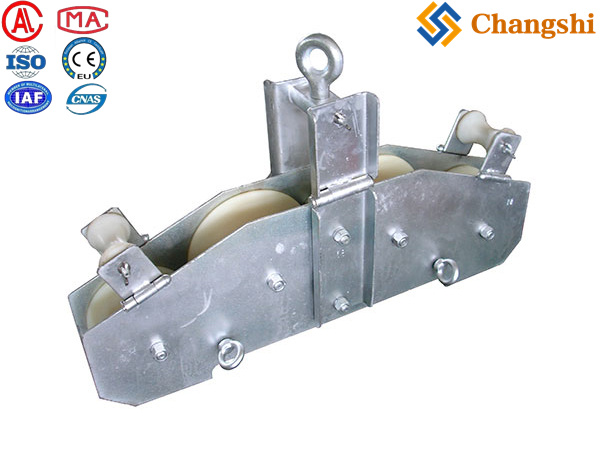

Urethane or Neoprene Lined Aluminum: Aluminum sheaves with a thick, soft lining of polyurethane or neoprene are also widely used. The lining cushions the cable and prevents damage.

No Steel Sheaves: Steel sheaves are generally avoided as they can be too abrasive and potentially damage the delicate jacket or the cable itself.

Specific Groove Profile: The sheave groove is precisely shaped to cradle the OPGW or ADSS cable, ensuring it sits securely and is evenly supported, preventing localized stress points.

High-Quality, Sealed Bearings: Critical for smooth, frictionless rotation, which is vital for maintaining constant tension and preventing jerking motions that could stress the fibers.

Robust, Lightweight Frame: While protecting the cable, the blocks also need to be durable enough to withstand the stringing loads and often lightweight for ease of installation (especially for helicopter deployment). Frames are typically made from aluminum alloy.

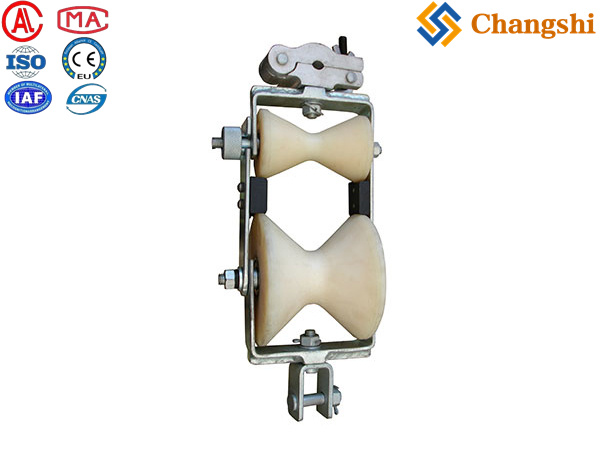

"Small Groove" or "Double Groove" (for OPGW): Some OPGW blocks have a unique design that includes a smaller, secondary groove or channel at the bottom of the main groove. This is for the pilot rope. This allows the pilot rope to be strung first using the same block, and then the OPGW can be pulled in without removing the pilot rope from the groove. This feature is particularly useful for reducing setup time.

OPGW vs. ADSS Considerations:

OPGW: Often pulled at higher tensions as it functions as a ground wire. The blocks must be robust but still protect the fibers. The primary concern is protecting the outer strands and fibers from crushing or bending damage.

ADSS: Being all-dielectric, its outer jacket is crucial for insulation. The blocks must be even gentler to avoid any nicks or cuts in the jacket that could compromise its dielectric integrity. Low tension stringing is generally preferred for ADSS.