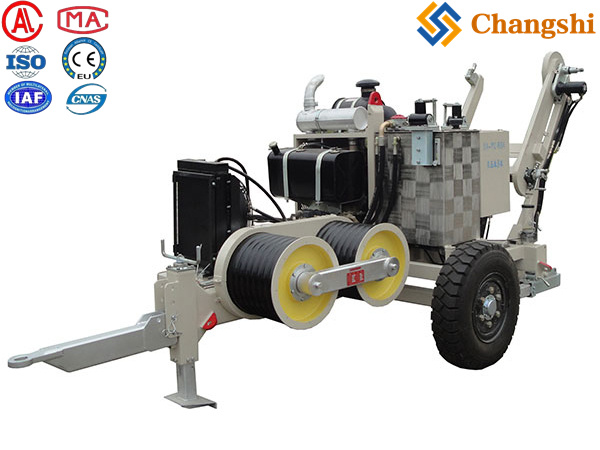

High-Capacity Pullers for EHV/UHV lines

High-capacity hydraulic pullers are essential for the safe and efficient stringing of conductors for Extra High Voltage (EHV) and Ultra High Voltage (UHV) transmission lines.

Specific Requirements for High-Capacity Pullers for EHV/UHV Lines:

The sheer scale and complexity of EHV (typically 110 kV and above, with 765 kV being a common EHV threshold) and UHV (often ±800 kV DC or 1000 kV AC) lines demand pullers with very specific capabilities:

-

Immense Pulling Force: EHV/UHV lines often involve large, heavy conductors, and sometimes multiple conductors bundled together. This requires pullers capable of generating pulling forces significantly higher than those for standard distribution lines, often in the range of 10 to 40 tons (100 to 400 KN) or even higher. For example, some pullers go up to 420 KN (42 tons).

-

Precision Control: Despite the high force, precise control over pulling speed and tension is paramount. Conductors, especially bundled ones, are expensive and delicate. Over-tensioning can damage the conductor, insulators, or even towers.

-

Automatic Tension/Pull Control Systems: These are crucial for maintaining constant tension and preventing overloads. They can automatically adjust speed and force.

-

Infinitely Variable Speed: Allows for smooth starts and stops and adaptation to varying terrain and conditions.

-

-

Durability and Reliability: EHV/UHV line construction often takes place in remote, challenging environments and under tight schedules. The equipment must be robust, reliable, and capable of continuous operation.

-

High-Quality Components: Use of top-tier hydraulic pumps, motors (e.g., Rexroth), and reducers (e.g., Italian RR) is standard.

-

Wear-Resistant Materials: Bullwheels are often made with high-resistance, interchangeable nylon sectors to prevent damage to the conductor.

-

-

Multi-Conductor Pulling Capability: Many EHV/UHV lines use bundled conductors (multiple parallel cables) to reduce corona discharge and increase capacity.

Pullers designed for these applications can string multiple conductors simultaneously. -

Advanced Monitoring and Safety Features:

-

Digital Interfaces: Provide real-time data on pulling force, speed, and distance.

-

Integrated Pull and Speed Recorders: For documentation and analysis.

-

Negative Self-Acting Hydraulic Brake: For immediate and secure stopping.

-

Hydraulic Oil Cooling System: To prevent overheating during prolonged operation.

-

Electronic Synchronization: For controlling multiple machines when complex stringing configurations are required.

-

Radio Remote Control: Enhances safety and operational flexibility.

-

-

Mobility and Adaptability: While often large, these machines still need to be transportable to various job sites, which might be in difficult terrain.

-

Trailer-mounted or truck-mounted designs.

-

Some specialized units might even be designed for breakdown and transport by helicopter for extremely remote locations.

-