Earthing Rods & Clamps

Earthing rods (often called ground rods in North America) and the clamps that connect conductors to them are foundational components of any effective grounding system. They provide the essential physical connection to the earth, creating a low-resistance path for electrical currents to dissipate safely.

Earthing Rods: The Earth Connection

Earthing rods are long, conductive electrodes driven into the ground to provide a stable, low-impedance electrical connection to the general mass of the earth. The effectiveness of an earthing rod depends heavily on its material, dimensions, and the resistivity of the surrounding soil.

Types and Materials of Earthing Rods:

Copper-Bonded Steel Earth Rods:

Description: These are the most common and widely used type. They consist of a high-tensile, low-carbon steel core with a molecularly bonded outer layer of high-purity electrolytic copper.

Advantages:

Strength: The steel core provides mechanical strength, allowing them to be driven deep into hard ground without bending or breaking.

Conductivity: The copper layer provides excellent electrical conductivity.

Corrosion Resistance: The copper coating offers good corrosion resistance in most soil conditions, significantly extending the rod's lifespan compared to bare steel.

Cost-Effective: They offer a good balance of performance and cost compared to solid copper.

Standards: Often manufactured to standards like UL 467 (Grounding and Bonding Equipment) and IEC 62561-2 (Lightning Protection System Components - Part 2: Requirements for conductors and earth electrodes). The copper bonding thickness (e.g., 254 microns or 375 microns minimum) is crucial for longevity and standard compliance.

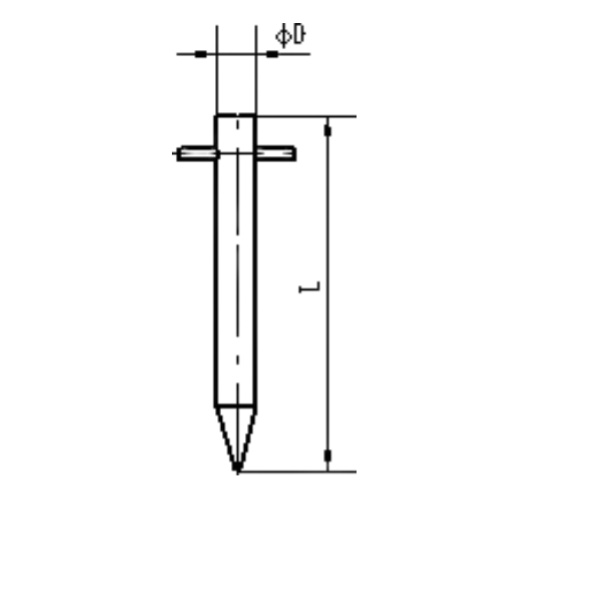

Variations: Available as pointed rods (for driving directly) or threaded rods (for coupling multiple rods together to achieve greater depth).

Solid Copper Earth Rods:

Description: Made entirely of pure, hard-drawn copper.

Advantages:

Excellent Conductivity: Highest electrical conductivity among common rod materials.

Superior Corrosion Resistance: Best resistance to corrosion, especially in highly corrosive or alkaline soils.

Disadvantages:

Higher Cost: Significantly more expensive than copper-bonded rods.

Lower Mechanical Strength: More prone to bending or damage if driven into very hard or rocky ground.

Applications: Often used in specialized applications where very low earth resistance is paramount, or in highly corrosive environments where the longevity of copper is critical despite the cost.

Galvanized Steel Earth Rods:

Description: Steel rods coated with a layer of zinc (hot-dip galvanized) for corrosion protection.

Advantages:

Cost-Effective: The most economical option.

Good Strength: Robust for driving.

Disadvantages:

Lower Conductivity: Zinc and steel are less conductive than copper.

Limited Corrosion Resistance: The zinc coating can degrade over time, especially in aggressive soils, leading to rust.

Applications: Suitable for less critical applications or where budget is a primary concern, and soil conditions are not overly aggressive.

Stainless Steel Earth Rods:

Description: Made from stainless steel (e.g., 304 or 316 grade).

Advantages:

Excellent Corrosion Resistance: Particularly good in highly acidic soils or environments with high salt content (e.g., coastal areas).

Disadvantages:

Lower Conductivity: Less conductive than copper or copper-bonded steel.

High Cost: Can be comparable to or even more expensive than solid copper rods.

Applications: Niche applications in very specific highly corrosive environments.

Dimensions: Earthing rods typically come in standard diameters (e.g., 1/2", 5/8", 3/4", 1") and lengths (e.g., 4ft, 8ft, 10ft, 12ft, 20ft). Multiple rods are often driven and coupled together to achieve deeper penetration and lower resistance.

Earthing Clamps: The Crucial Connection

Earthing clamps (also known as ground rod clamps or conductor-to-rod clamps) are mechanical connectors used to securely join an earthing conductor (e.g., bare copper wire, braided conductor) to an earthing rod. A good clamp ensures a low-resistance, high-current-capacity, and mechanically robust connection that can withstand environmental conditions and fault currents.

Types and Materials of Earthing Clamps:

"Acorn" or "Pipe" Clamps:

Description: A common type, often made of brass or bronze alloy. They typically feature a U-bolt or a single bolt design that tightens onto the rod, clamping the conductor against the rod. (Helix Steel Products search result shows a ground rod clamp with hexagonal head bolt).

Materials: Copper alloy (bronze or brass) for good conductivity and corrosion resistance. Some lower-cost options may use galvanized steel or zinc alloy.

Features: Designed for direct burial, suitable for connecting bare copper wire to ground rods. Available for various rod diameters and conductor sizes.

Applications: General purpose connection of grounding conductors to ground rods in residential, commercial, and light industrial settings.

U-Bolt Rod Clamps:

Description: Utilize a U-shaped bolt with nuts to tightly clamp the conductor against the rod.

Materials: High-grade copper alloy or stainless steel.

Applications: Often used in structural earthing systems to connect rebar or earth rods to flat or stranded conductors.

Split Bolt Connectors (for conductors to conductors):

While not strictly "ground rod clamps," split bolts are often used in grounding systems to make connections between multiple grounding conductors or to splice them. They provide a strong mechanical and electrical connection.

Key Considerations for Clamps:

Material Compatibility: The clamp material should be galvanically compatible with both the earthing rod and the conductor to prevent accelerated corrosion (e.g., copper clamp for copper/copper-bonded rod and copper conductor).

Corrosion Resistance: Crucial for buried applications. Look for clamps approved for direct burial in earth and concrete.

Mechanical Strength: Must provide a secure, long-lasting connection that won't loosen due to vibration, thermal expansion/contraction, or soil movement.

Current Carrying Capacity: Must be able to safely carry the maximum fault current expected without overheating or melting.

Ease of Installation: Simple, reliable installation is important for field work.

Standards: Clamps should meet relevant standards like UL 467 (for grounding and bonding equipment).

Exothermic Welding (Cadweld) for Permanent Connections:

While clamps provide a good mechanical connection, for critical, permanent grounding connections (especially in substations, power plants, and transmission towers), exothermic welding (like nVent ERICO Cadweld) is often preferred. This process creates a molecular bond between conductors and/or electrodes, offering:

Superior Conductivity: A permanent, fused connection with very low resistance.

Exceptional Durability: Highly resistant to corrosion, mechanical stress, and loosening over time.

High Fault Current Withstand: Can safely carry very high fault currents without degradation.