30 Ton Hydraulic Conductor Puller | Extreme Scale OHTL Stringing

Experience unparalleled power with Ningbo Changshi's 30-ton hydraulic conductor puller. Engineered for extreme-scale OHTL projects & global heavy-duty applications. Your trusted China manufacturer.

- Transmission Line Wire Cable Conductor Tension Stringing Equipment

- Transmission Conductor Tension Stringing Equipment For Overhead Power Lines

- Tools For Power Lines,Substation,Electrical Construction & Maintenance

- Electric Power Transmission Distribution Line Construction Machine Tools

- Overhead Power Transmission Distribution Line Repair Hardware Fittings

- Underground Cable Laying Pulling Installation Equipment Machine Tools Accessories

- Information

- Video

30 Ton Hydraulic OHTLstringingequipment.com/Hydraulic-Conductor-Pullers.html target='_blank'>Conductor Puller: Unmatched Force for Global Ultra-High Voltage OHTL Projects

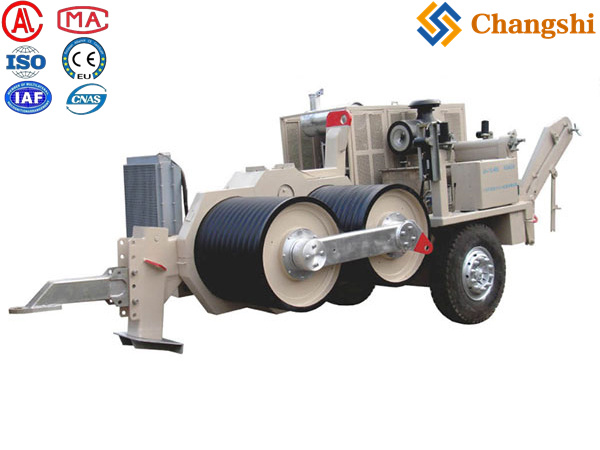

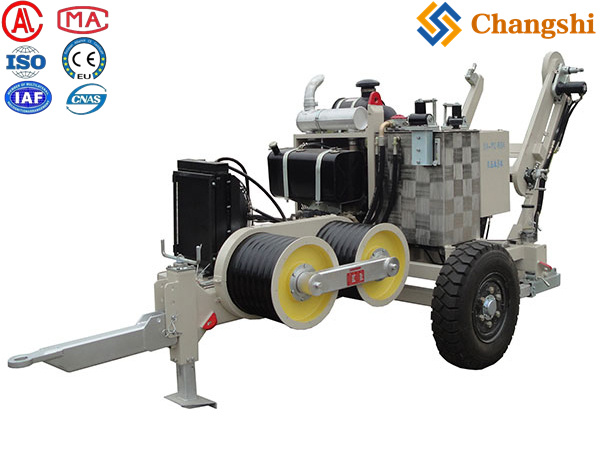

On behalf of Ningbo Changshi Electric Power Machinery Manufacturing Limited, a prominent China manufacturer and global exporter, we are thrilled to introduce our pinnacle achievement in conductor stringing technology: the 30 Ton Hydraulic Conductor Puller. This monumental machine is meticulously engineered to address the most formidable demands of extreme-scale overhead transmission line (OHTL) stringing operations. It stands as the definitive solution for the largest, most complex, and strategically critical power infrastructure developments across the globe.

Product Features & Benefits:

The Ningbo Changshi 30 Ton Hydraulic Conductor Puller is designed for unparalleled strength, surgical precision, and relentless reliability. It ensures the seamless, precise, and unequivocally safe handling of the heaviest, largest-diameter, or multiple bundled conductors over exceptionally long spans and through the most challenging, remote terrains, safeguarding your invaluable assets.

-

Ultimate 30-Ton Pulling Capacity: Offers an astonishing 300 kN (30 Ton) of continuous pulling force, setting a new industry benchmark. This makes it the definitive solution for the heaviest conductors, record-breaking ultra-long distance pulls, and the most complex multi-bundled conductor stringing configurations in grand-scale, UHV (Ultra-High Voltage) transmission projects.

-

Next-Generation Hydraulic Precision: Equipped with a state-of-the-art, high-pressure closed hydraulic circuit, featuring premium-grade, globally recognized components (e.g., top-tier Rexroth, Sauer-Danfoss). This sophisticated system allows for infinitely variable speed control and ultra-precise, digitally monitored tension management, ensuring absolute control and eliminating any risk of conductor damage under the most extreme loads.

-

Engineered for Extreme Durability & Longevity: Constructed with an exceptionally reinforced, anti-corrosion treated heavy-duty steel chassis, oversized structural components, and superior-grade materials throughout. This machine is built for extreme resilience against continuous, high-intensity operations and the most severe environmental conditions, guaranteeing unparalleled operational life and maximum structural integrity.

-

Advanced Multi-Tiered Safety System: Incorporates a robust automatic spring-applied, hydraulic-released brake system for instantaneous and fail-safe braking. A comprehensive over-pulling protection system, an integrated multi-point emergency stop system, and sophisticated real-time diagnostic monitoring provide the highest possible level of safety for both highly skilled personnel and multi-million-dollar conductor assets.

-

Maximum Output Industrial Powerhouse: Driven by an exceptionally high-performance, water-cooled industrial diesel engine (e.g., top-tier Cummins, Deutz, Caterpillar equivalent), meticulously optimized for consistent, maximum power delivery, superior torque, and optimal fuel efficiency even during the most demanding, prolonged pulling tasks.

-

Intuitive & Comprehensive Operator Interface: Features an advanced, ergonomic control panel with large, crystal-clear digital instrumentation and integrated diagnostic displays for real-time monitoring of pulling force, speed, engine parameters, and critical system indicators. This empowers operators with unparalleled control and simplifies even the most complex operations.

Product Applications:

Our 30 Ton Hydraulic Conductor Puller is specifically designed and highly recommended for:

-

Ultra-High Voltage (UHV) transmission line Construction: The ultimate solution for handling the massive conductors and complex bundles required for 500kV, 750kV, 1000kV, and future higher voltage lines.

-

Complex Multi-Bundled Conductor Stringing: Efficiently and safely pulling intricate bundles of 6, 8, or more conductors simultaneously over challenging distances.

-

Extreme Long-Span Crossings: Ideal for critical pulling operations over vast distances such as major river crossings, deep valleys, high mountain passes, and dense urban environments where intermediate tension points are minimal.

-

Super Heavy-Duty Re-conductoring Projects: Replacing existing large-diameter conductors with new, heavier, or larger capacity ones in the most demanding and sensitive environments.

-

Global Large-Scale Infrastructure Projects: Providing robust and reliable performance for national grid expansions, international interconnections, and remote large-scale power infrastructure development.

Why Choose Ningbo Changshi Electric Power Machinery Manufacturing Limited or Partner With Us?

At Ningbo Changshi, we offer comprehensive one-stop supply and services for both overhead transmission line wire cable conductor tension stringing equipment and underground cable laying equipment. Our steadfast commitment to global excellence is reflected in:

-

Leading Chinese Manufacturer: We leverage advanced manufacturing techniques, state-of-the-art facilities, and a relentless pursuit of innovation to produce equipment that sets industry benchmarks for quality, reliability, and performance.

-

Unrivaled Expertise & Global Reach: With decades of experience, we understand the nuances of power line projects worldwide. We export our equipment and tools globally, backed by a dedicated team that provides expert technical support and comprehensive after-sales service across continents.

-

Innovation Driven by Demand: We continuously invest in research and development, incorporating the latest technological advancements to deliver highly efficient, safe, and durable solutions that address the evolving needs of the global power industry.

-

Tailored Solutions & Partnership Approach: We work collaboratively with our international clients, understanding their unique project requirements. We offer customized solutions and provide expert guidance from initial consultation and equipment selection through to successful project completion.

-

Comprehensive Product Portfolio: Streamline your procurement process by sourcing all your OHTL stringing equipment, overhead tools & accessories, and underground cable laying equipment & tools from a single, trusted, and prominent partner.

Technical Data Sheet: 30 Ton Hydraulic Conductor Puller

Note: Specifications are indicative of an extreme heavy-duty model designed for the largest and most demanding applications. Exact values may vary significantly based on specific model configurations, customization requirements, and continuous product improvements. For the most current and precise technical data, or to discuss custom solutions for your mega-scale projects, please contact our sales team directly.

At Ningbo Changshi Electric Power Machinery Manufacturing Limited, we are committed to being your reliable partner in constructing and maintaining the world's power infrastructure. Our 30 Ton Hydraulic Conductor Puller is a testament to our dedication to innovation, quality, and extreme performance.

Elevate your most ambitious power line projects to an unprecedented level of efficiency, precision, and safety. Contact Ningbo Changshi today to discuss how our 30 Ton Hydraulic Conductor Puller can provide the ultimate solution for your extreme-scale overhead transmission line stringing challenges. Request a custom quote or schedule a detailed technical consultation with our experts!