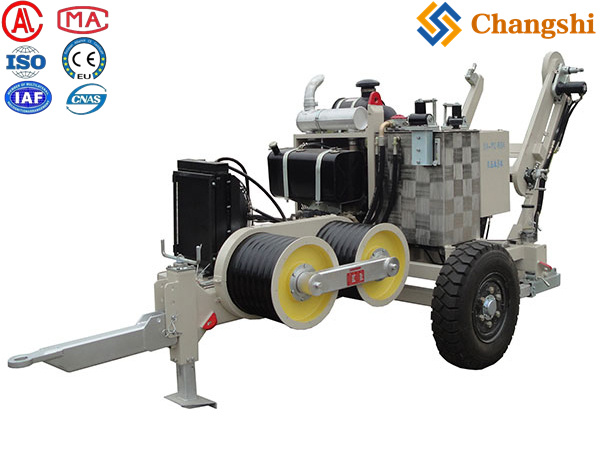

18 Ton Hydraulic Conductor Puller | Ultra Heavy-Duty OHTL

Power your largest projects with our ultra heavy-duty 18-ton hydraulic conductor puller. Engineered for mega-scale OHTL stringing & complex conductor installations. Global China exporter.

- Transmission Line Wire Cable Conductor Tension Stringing Equipment

- Transmission Conductor Tension Stringing Equipment For Overhead Power Lines

- Tools For Power Lines,Substation,Electrical Construction & Maintenance

- Electric Power Transmission Distribution Line Construction Machine Tools

- Overhead Power Transmission Distribution Line Repair Hardware Fittings

- Underground Cable Laying Pulling Installation Equipment Machine Tools Accessories

- Information

- Video

18 Ton Hydraulic OHTLstringingequipment.com/Hydraulic-Conductor-Pullers.html target='_blank'>Conductor Puller: Unrivaled Power for Mega-Scale OHTL Stringing

As a prominent China manufacturer and global exporter specializing in robust tools and equipment for power lines, substations, and electrical construction, [Your Company Name] proudly introduces our flagship, ultra heavy-duty 18 Ton Hydraulic Conductor Puller. This formidable machine is specifically engineered to meet the extreme demands of mega-scale overhead transmission line (OHTL) stringing operations, making it an indispensable asset for the most challenging and critical infrastructure projects worldwide.

Designed for unparalleled strength, precision, and continuous reliability, our 18 Ton Hydraulic Conductor Puller delivers an colossal pulling force, ensuring smooth, precise, and safe handling of the largest or multiple bundled conductors over exceptionally long spans and highly complex terrains. Its advanced hydraulic system provides meticulous control, crucial for protecting valuable wire and cables during installation and re-conductoring, thereby optimizing efficiency, minimizing risks, and ensuring the integrity of your most valuable assets on the job site.

Key Features & Benefits:

-

Unrivaled 18-Ton Pulling Capacity: Offers an astounding 180 kN (18 Ton) of continuous pulling force, making it the ultimate solution for the heaviest conductors, ultra-long distance pulls, and complex multi-bundled conductor stringing in grand-scale transmission projects.

-

Precision Hydraulic Powerhouse: Equipped with a state-of-the-art closed hydraulic circuit, featuring premium-grade global components (e.g., Rexroth, Sauer-Danfoss). This system allows for infinitely variable speed control and ultra-precise tension management, ensuring controlled pulling operations and preventing conductor damage even under extreme loads.

-

Engineered for Extreme Durability: Constructed with a heavily reinforced, anti-corrosion treated steel chassis, oversized components, and superior-grade materials throughout. This ensures exceptional resilience against continuous, high-intensity operations and the most severe environmental conditions, guaranteeing extended operational life and minimal structural fatigue.

-

Advanced Multi-Layered Safety System: Includes a robust automatic spring-applied, hydraulic-released brake system for instantaneous and secure braking. Comprehensive over-pulling protection, an integrated emergency stop system, and real-time diagnostic monitoring provide unparalleled safety for both personnel and multi-million-dollar conductor assets.

-

High-Output Industrial Engine: Powered by a high-performance, water-cooled industrial diesel engine (e.g., Cummins, Deutz, Caterpillar equivalent), meticulously optimized for consistent, maximum power delivery and fuel efficiency during the most demanding, prolonged pulling tasks.

-

Intuitive Operator Interface: Features an advanced, ergonomic control panel with clear, large instrumentation and digital displays for real-time monitoring of pulling force, speed, engine parameters, and diagnostic indicators, enhancing operator control and simplifying complex operations.

-

Global Project Proven: Manufactured under the strictest quality control protocols and engineered to exceed international quality and safety standards, this equipment is a proven, dependable solution for leading electrical contractors and utilities undertaking the world's most ambitious power infrastructure developments.

At Changshi, we offer comprehensive one-stop supply and services for both overhead transmission line wire cable conductor tension stringing equipment and underground cable laying equipment. Choose our 18 Ton Hydraulic Conductor Puller for an unmatched combination of power, precision, and reliability on your most critical and extensive power infrastructure endeavors.

Technical Data Sheet: 18 Ton Hydraulic Conductor Puller

Note: Specifications are indicative of an ultra heavy-duty model designed for the largest and most demanding applications. Exact values may vary significantly based on specific model configurations, customization, and continuous product improvements. For the most current and precise technical data, or to discuss custom solutions for your mega-scale projects, please contact our sales team directly.