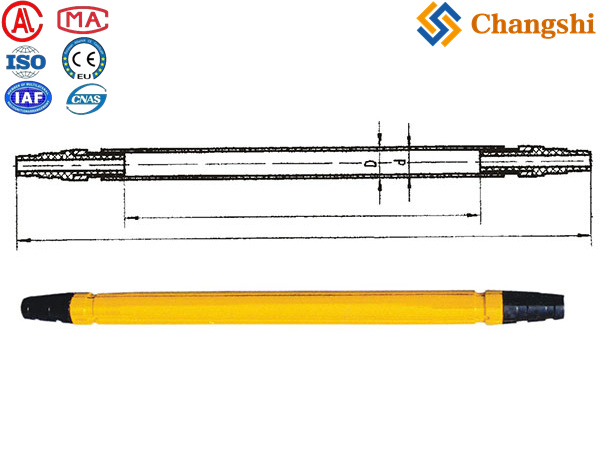

U-Shaped Anti-Bending Link for Power Line Stringing

Prevent bending and kinking during power line stringing with Ningbo Changshi's U-shaped bend-resistant connector. Ensures smooth, damage-free conductor installation.

- Transmission Line Wire Cable Conductor Tension Stringing Equipment

- Transmission Conductor Tension Stringing Equipment For Overhead Power Lines

- Tools For Power Lines,Substation,Electrical Construction & Maintenance

- Electric Power Transmission Distribution Line Construction Machine Tools

- Overhead Power Transmission Distribution Line Repair Hardware Fittings

- Underground Cable Laying Pulling Installation Equipment Machine Tools Accessories

- Information

- Video

U-Shaped Anti-Bending Link: Safeguarding Conductors During Power line stringing Operations

At Ningbo Changshi Electric Power Machinery Manufacturing Limited, we understand that the demanding process of overhead transmission line (OHTL) stringing requires meticulous attention to every detail, especially when it comes to preventing damage to expensive conductors and crucial pulling equipment. Unwanted bending, kinking, or severe angular stress on pilot wires, pulling ropes, or conductors can lead to significant setbacks, compromising material integrity and delaying project completion. Our U-Shaped Anti-Bending Link for Power line stringing is a meticulously engineered, specialized connector designed to directly counter these challenges. Characterized by its robust "U-shape," this link provides exceptional "bend resistance," ensuring that the pulling forces are distributed smoothly and that rotational stresses are effectively managed, preventing detrimental kinks and twists. It is a vital component for ensuring a continuous, controlled, and damage-free stringing process. As a prominent China manufacturer and exporter specializing in comprehensive one-stop supply for both overhead transmission line (OHTL) wire cable conductor tension stringing equipment and underground cable laying equipment, this U-shaped bend resistance connector exemplifies our unwavering commitment to providing innovative, durable, and highly effective equipment that ensures superior safety, efficiency, and the long-term performance of your critical power line construction projects.

The unique "U-shape" design of this connector plays a crucial role in its anti-bending and anti-kinking capabilities. This geometry typically allows for a broad distribution of load and often incorporates an integrated Swivel mechanism, ensuring that any torsional forces generated during the pull are absorbed, preventing their transfer to the conductor or other sensitive components. This rotational freedom, coupled with the inherent structural strength of the U-shape, maintains the linear integrity of the pulling system. Crafted from high-strength, corrosion-resistant materials, our U-Shaped Anti-Bending Link is built to withstand the rigorous tensile forces encountered during conductor stringing, guaranteeing reliable performance even in the most challenging environments. It serves as a critical interface point, commonly used between the pulling rope, Swivel, and conductor grip, or between various tensioning equipment components. By incorporating this specialized connector into your stringing setup, you significantly mitigate the risk of costly material damage, enhance worker safety, and achieve a more efficient and precise power line installation.

Product Features & Benefits:

-

Distinctive U-Shape Design: Engineered to provide superior anti-bending and anti-kinking properties, effectively managing angular stress and preventing damage to pulling ropes, pilot wires, and conductors during stringing.

-

Integrated Swivel Functionality (Common): Most models incorporate a robust swivel that allows for free rotation between connected components, absorbing torsional forces and preventing the accumulation of twist in the conductor or pulling line.

-

High Strength & Durability: Manufactured from robust, high-grade alloy steel or aluminum, precisely forged and treated to withstand immense tensile loads and resist wear in demanding outdoor construction environments.

-

Corrosion Resistance: Features protective finishes (e.g., hot-dip galvanization, advanced coatings) or is made from inherently corrosion-resistant materials for extended service life in diverse weather conditions.

-

Smooth & Controlled Pulling: Facilitates a linear and consistent pulling force, reducing friction and stress on both equipment and conductors, leading to a more efficient and safer stringing operation.

-

Optimized Load Distribution: The U-shape geometry helps in distributing pulling forces evenly, reducing localized stress points on the attached components.

-

Protects Conductors & Equipment: Directly prevents costly damage to conductors from kinking, spiraling, and other deformities that compromise structural and electrical integrity.

-

Enhanced Safety: Contributes to a safer worksite by mitigating sudden jerks or snags often caused by twisting lines, allowing for more predictable and controlled pulling operations.

-

Wide Range of Load Capacities: Available in various sizes and breaking strengths to accommodate different conductor types, pulling tensions, and project requirements.

Product Applications:

Our U-Shaped Anti-Bending Link is an essential component for various overhead transmission line (OHTL) construction and maintenance applications:

-

conductor stringing Operations: Used as a critical link between the pulling rope, swivel, and conductor grip to prevent twisting and bending during the installation of new power lines.

-

Pilot Wire and Pulling Rope Connections: Ensures that pilot wires and main pulling ropes remain free of twists as they are navigated through Stringing Blocks and Tensioners.

-

Tension Stringing Systems: Integrates into comprehensive tension stringing setups, connecting various equipment components (e.g., pulling machines, dynamometers, conductor carts) where angular stability and twist prevention are vital.

-

Complex Route Stringing: Particularly beneficial in stringing operations over uneven terrain or around obstacles where the pulling line may experience increased rotational forces.

-

underground Cable Pulling (Specific Applications): Can be employed in certain underground cable pulling scenarios, especially for larger diameter cables where maintaining cable integrity during twists is a concern.

-

Heavy-Duty Rigging: Suitable for general heavy-duty rigging applications where anti-bending and swivel capabilities are required under significant tensile loads.

Technical Data Sheet:

Note: Always select a U-shaped anti-bending link with a Working Load Limit (WLL) that significantly exceeds the maximum anticipated tension during your stringing operation. NEVER exceed the stated WLL. Thorough inspection for any signs of wear, fatigue, cracks, or corrosion is mandatory before each use. Any damaged or excessively worn connectors must be immediately removed from service. Ensure the swivel mechanism operates smoothly and freely under load. Please contact us for detailed datasheets for specific models and their exact load capacities and dimensions.

Why Choose Ningbo Changshi Electric Power Machinery Manufacturing Limited?

Choosing Ningbo Changshi means partnering with a trusted industry leader dedicated to providing high-performance, safe, and efficient equipment for your overhead transmission line projects. Here’s why our U-Shaped Anti-Bending Link is your ideal choice:

-

Superior Anti-Bending & Kink Prevention: Our unique U-shape design, combined with robust swivel functionality, effectively eliminates kinks and twists, safeguarding conductors and ensuring a smooth, controlled stringing operation.

-

Protects Critical Assets: By preventing harmful bending and torsional stress, our link extends the lifespan of expensive conductors and pulling ropes, significantly reducing material damage and replacement costs.

-

Enhances Operational Efficiency & Safety: Contributes to a more predictable and linear pulling process, minimizing snags, delays, and improving overall safety for crews during complex stringing tasks.

-

Comprehensive One-Stop Supply Chain Mastery: As a preeminent manufacturer and exporter, we offer an unparalleled array of cutting-edge equipment for both overhead transmission line and underground cable laying projects, streamlining your entire procurement process with a single, reliable source for all your specialized Stringing Accessories.

-

Global Trust & Proven Excellence: Our unwavering commitment to quality, innovation, and safety has earned us the trust of leading power utilities and electrical contractors worldwide, making us the preferred choice for reliable, high-performance OHTL stringing equipment.

Final Summary:

Our U-Shaped Anti-Bending Link is an indispensable, meticulously engineered accessory designed for seamless and damage-free overhead transmission line stringing operations. Its robust U-shape and integrated swivel effectively prevent bending and kinking of conductors and ropes under tension, ensuring a smooth, controlled, and efficient pulling process. Trust Ningbo Changshi Electric Power Machinery Manufacturing Limited to equip your teams with high-quality, dependable, and intelligently designed components that are fundamental to achieving superior efficiency, safety, and project success for all your power line construction needs.

Ensure ultimate protection against bending and kinking during power line stringing! Explore our U-Shaped Anti-Bending Links. Visit