Anti-Twist Line Stringing Swivel for Cable Pulling

Prevent twisting and kinking during overhead or underground cable pulling with Ningbo Changshi's robust anti-twist line stringing swivel. Essential for smooth, damage-free installations.

- Transmission Line Wire Cable Conductor Tension Stringing Equipment

- Transmission Conductor Tension Stringing Equipment For Overhead Power Lines

- Tools For Power Lines,Substation,Electrical Construction & Maintenance

- Electric Power Transmission Distribution Line Construction Machine Tools

- Overhead Power Transmission Distribution Line Repair Hardware Fittings

- Underground Cable Laying Pulling Installation Equipment Machine Tools Accessories

- Information

- Video

Anti-Twist line stringing Swivel: Ensuring Smooth & Damage-Free Cable Pulling Operations

At Ningbo Changshi Electric Power Machinery Manufacturing Limited, we understand that successful and efficient overhead transmission line (OHTL) and underground cable laying operations critically depend on preventing torsional stresses that can lead to costly damage and operational delays. The twisting and kinking of conductors, pilot wires, and pulling ropes are common challenges that can compromise cable integrity and slow down projects. Our Anti-Twist line stringing Swivel is an indispensable, precision-engineered component specifically designed to mitigate these issues. Its core function is to allow free rotation between the pulling rope and the cable or conductor, effectively absorbing and neutralizing torsional forces generated during the stringing process. This ensures a smooth, continuous pull, protecting valuable assets and significantly enhancing both efficiency and safety on the job site. As a prominent China manufacturer and exporter specializing in comprehensive one-stop supply for both overhead transmission line (OHTL) wire cable conductor tension stringing equipment and underground cable laying equipment, this line stringing swivel exemplifies our unwavering commitment to providing innovative, durable, and highly effective equipment that ensures superior safety, efficiency, and the long-term performance of your power infrastructure projects.

The Line Stringing Swivel is a seemingly simple yet profoundly important device in cable pulling mechanics. Its primary role is to act as a crucial interface, allowing the conductor, pilot wire, or rope to rotate freely around its axis relative to the pulling line. This rotational freedom prevents the accumulation of twist, which can otherwise cause the conductor to spiral, damage its outer layers, or even lead to severe kinking, especially when pulling long lengths or navigating bends. Manufactured from high-strength, durable materials like forged alloy steel, and incorporating robust ball bearings or thrust bearings, our swivels are built to operate smoothly even under immense tensile loads. They are widely used in a variety of stringing applications, from pulling large overhead transmission conductors across spans to guiding heavy power cables through underground conduits. By integrating our reliable anti-twist line stringing swivel into your setup, you ensure a significantly cleaner pull, extend the life of your conductors and pulling equipment, and reduce the overall risk and complexity of your cable installation projects.

Product Features & Benefits:

-

Exceptional Anti-Twist Functionality: Features a robust internal bearing system (e.g., sealed ball bearings or thrust bearings) that allows for 360-degree free rotation under load, effectively preventing torsional forces from building up and causing twists or kinks in conductors and ropes.

-

High Strength & Durability: Manufactured from high-grade, forged alloy steel, meticulously heat-treated for maximum strength and wear resistance, ensuring reliable performance under extreme tension.

-

Corrosion Resistance: Protected with durable finishes (e.g., hot-dip galvanization, zinc plating, or powder coating) to withstand harsh outdoor environments and prolong service life.

-

Smooth Operation Under Load: Engineered to maintain smooth rotational performance even when subjected to high pulling tensions, reducing friction and stress on the entire stringing system.

-

Reduces Conductor & Rope Damage: Protects valuable conductors from spiraling, kinking, and structural damage caused by uncontrolled twisting, extending their lifespan and ensuring optimal electrical performance.

-

Versatile Connection Points: Equipped with robust eyes or shackles at both ends for easy and secure attachment to pulling grips, pilot wires, pulling ropes, dynamometers, and other stringing equipment.

-

Enhanced Safety: Prevents sudden jerks or unpredictable movements of the pulling line that can occur due to twist accumulation, contributing to a safer working environment for line crews.

-

Increases Efficiency: Facilitates a smoother, faster, and more controlled pulling operation, reducing delays and improving overall project productivity.

-

Wide Range of Capacities: Available in various sizes and Working Load Limits (WLL) to suit different conductor diameters, pulling tensions, and project scales.

Product Applications:

Our Anti-Twist Line Stringing Swivel is an indispensable tool across a broad spectrum of power line construction and maintenance applications:

-

Overhead Transmission Line Stringing: Essential for pulling large conductors (ACSR, AAC, AAAC) over long spans, connecting pulling ropes to Conductor Grips to prevent twisting.

-

underground cable Laying: Used in conduit pulls and open trench installations for medium and high voltage power cables to ensure the cable remains untwisted as it's pulled.

-

Pilot Wire Installation: Connects the pilot wire to the pulling rope, allowing the pilot wire to follow the path without kinking, especially through multiple bends or rollers.

-

Tension Stringing Operations: Integrates into complex tension stringing setups, where it's crucial to manage torsional forces between the Tensioner, pulling machine, and conductor.

-

Heavy Industrial Cable Pulls: For installing large power cables in industrial facilities, factories, and utility tunnels where maintaining cable integrity is critical.

-

Optical Fiber cable stringing: Can be used for stringing sensitive optical fiber cables where preventing twist and torsion is paramount to avoid fiber damage.

-

General Rigging & Pulling: Applicable in any heavy pulling or towing scenario where rotational forces need to be absorbed to protect ropes, chains, or cables.

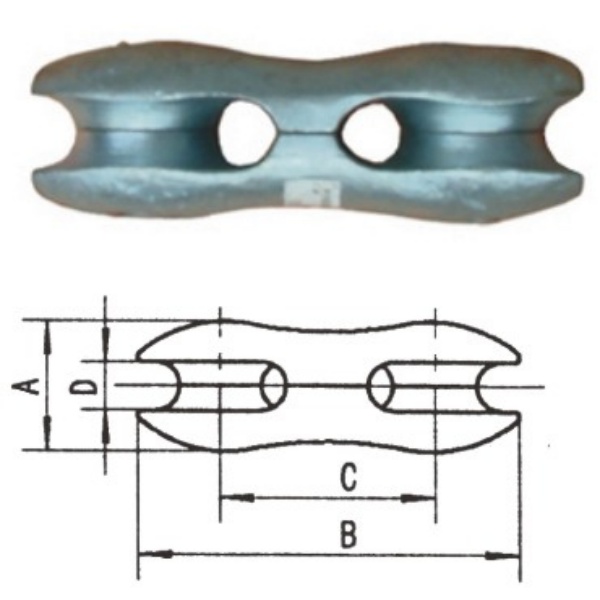

Technical Data Sheet:

Note: Always select a line stringing swivel with a Working Load Limit (WLL) that significantly exceeds the maximum anticipated tension during your cable pulling operation. NEVER exceed the stated WLL. Regular inspection for any signs of wear, deformation, cracks, or corrosion, particularly on the eyes and bearing housing, is mandatory before each use. Any damaged or excessively worn swivels must be immediately removed from service. Ensure the swivel mechanism rotates smoothly and freely. Please contact us for detailed datasheets for specific models and their exact load capacities and dimensions.

Why Choose Ningbo Changshi Electric Power Machinery Manufacturing Limited?

Choosing Ningbo Changshi means partnering with a trusted industry leader dedicated to providing high-performance, safe, and efficient equipment for your power line and cable laying projects. Here’s why our Anti-Twist Line Stringing Swivel is your ideal choice:

-

Unmatched Anti-Twist Performance: Our swivels feature robust bearing systems that allow for genuine 360-degree rotation under load, completely eliminating torsional stresses that can damage conductors and ropes.

-

Protects Your Valuable Assets: By preventing kinks, spiraling, and structural damage, our swivels extend the lifespan of expensive conductors and pulling ropes, significantly reducing material waste and project costs.

-

Enhances Operational Efficiency & Safety: Facilitates a smoother, faster, and more predictable pulling process, minimizing snags, delays, and vastly improving safety for crews during complex stringing and laying tasks.

-

Comprehensive One-Stop Supply Chain Mastery: As a preeminent manufacturer and exporter, we offer an unparalleled array of cutting-edge equipment for both overhead transmission line and underground cable laying projects, streamlining your entire procurement process with a single, reliable source for all your specialized Stringing Accessories.

-

Global Trust & Proven Excellence: Our unwavering commitment to quality, innovation, and safety has earned us the trust of leading power utilities and electrical contractors worldwide, making us the preferred choice for reliable, high-performance stringing equipment.

Final Summary:

Our Anti-Twist Line Stringing Swivel is an indispensable, meticulously engineered component designed for seamless and damage-free cable pulling operations in both overhead and underground applications. Its superior anti-twist functionality effectively neutralizes torsional forces, ensuring conductors and ropes remain free from kinks and damage, leading to smoother, more efficient, and safer installations. Trust Ningbo Changshi Electric Power Machinery Manufacturing Limited to equip your teams with high-quality, dependable, and intelligently designed components that are fundamental to achieving superior efficiency, safety, and project success for all your power line construction needs.

Ensure smooth, kink-free cable pulling on every project! Explore our Anti-Twist Line Stringing Swivels. Visit