Autonomous Traction Machine for OPGW Stringing & Conductor Replacement

Revolutionize OPGW stringing and old conductor replacement with Ningbo Changshi's autonomous traction machine. Experience unmatched mobility, efficiency, and safety for overhead power line upgrades.

- Transmission Line Wire Cable Conductor Tension Stringing Equipment

- Transmission Conductor Tension Stringing Equipment For Overhead Power Lines

- Tools For Power Lines,Substation,Electrical Construction & Maintenance

- Electric Power Transmission Distribution Line Construction Machine Tools

- Overhead Power Transmission Distribution Line Repair Hardware Fittings

- Underground Cable Laying Pulling Installation Equipment Machine Tools Accessories

- Information

- Video

Autonomous Traction Machine: Revolutionizing OPGW Stringing & Conductor Replacement

At Ningbo Changshi Electric Power Machinery Manufacturing Limited, we understand that modern overhead transmission line projects are increasingly complex, demanding equipment that offers not only powerful pulling and tensioning capabilities but also enhanced mobility and efficiency on challenging job sites. The installation of new OPGW (Optical Ground Wire) and the critical task of replacing aging conductors often require machinery that can adapt to diverse terrains and operational needs. Our Autonomous Traction Machine for OPGW Stringing & Conductor Replacement is a groundbreaking solution meticulously engineered to provide superior performance as a "self-moving traction machine" designed "to spread OPGW and replace old conductor." This innovative machine significantly reduces the logistical challenges of traditional stringing operations, offering unprecedented autonomy and precision. As a prominent China manufacturer and exporter specializing in comprehensive one-stop supply for both overhead transmission line (OHTL) wire cable conductor tension stringing equipment and underground cable laying equipment, this autonomous traction machine exemplifies our unwavering commitment to providing cutting-edge, durable, and highly efficient solutions that enhance the safety, speed, and cost-effectiveness of your critical power and communication infrastructure upgrades.

The Autonomous Traction Machine integrates powerful hydraulic pulling/tensioning capabilities with a sophisticated self-propulsion system, allowing it to move independently along the stringing path or within the work area. This "self-moving" feature eliminates the need for separate prime movers or extensive site preparation for positioning, significantly accelerating setup times and increasing operational flexibility. When deployed "to spread OPGW," it delivers the precise, controlled tension essential for protecting delicate fiber optic cables, ensuring smooth payout and preventing damage. For "replacing old conductor," its robust traction system enables efficient removal of existing lines while simultaneously pulling in new conductors, often in a single, streamlined operation (reconductoring). The machine is equipped with durable, high-friction bull-wheels, advanced control systems for precise tension/pulling force management, and an intuitive operator interface. Its independent mobility is powered by a reliable engine, making it ideal for remote or difficult-to-access locations. By deploying Ningbo Changshi's Autonomous Traction Machine, you invest in a highly versatile and intelligent solution that redefines efficiency and safety in overhead line construction and modernization.

Product Features & Benefits:

-

Self-Moving / Autonomous Propulsion: Integrated drive system allows the machine to move independently along the stringing path, within substation yards, or between work sites, significantly reducing setup time, labor, and the need for external positioning equipment.

-

Dual Functionality (OPGW Stringing & Conductor Replacement): Capable of precisely tensioning and pulling sensitive OPGW fiber optic cables and simultaneously replacing old conductors, streamlining complex reconductoring projects.

-

Precision Tension/Pull Control: Advanced hydraulic closed-loop system ensures stepless speed variation and maintains constant pulling or tensioning force, critical for protecting delicate OPGW and ensuring controlled conductor replacement.

-

Robust Traction System: Equipped with powerful drive mechanisms (e.g., track-mounted or heavy-duty wheels) providing excellent grip and maneuverability on diverse terrains.

-

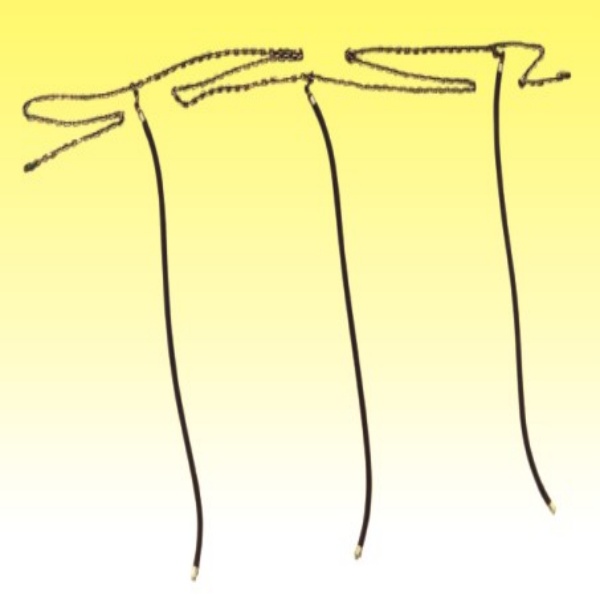

Optimized Bull-Wheels: Designed with specific groove profiles and high-friction, wear-resistant linings (e.g., multi-grooved nylon sectors or specialized rubber) suitable for both fiber optic cables and power conductors.

-

Integrated Monitoring & Control: Features a high-accuracy electronic dynamometer, speed indicators, meter counter, and intuitive controls for real-time operational data and precise management.

-

Enhanced Safety Protocols: Includes automatic negative hydraulic brake, emergency stop, secure grounding points, and operator safety enclosures to ensure maximum safety.

-

Powerful & Reliable Engine: Driven by a robust, water-cooled diesel engine (e.g., Cummins, Deutz, Yanmar) ensuring consistent performance and ample power for both traction and pulling/tensioning functions.

-

Reduced Logistical Footprint: Its self-moving capability minimizes the need for additional vehicles or heavy lifting equipment on site, leading to cost savings and environmental benefits.

-

Remote Operation Capability (Optional): Certain models can be equipped with remote control for enhanced operator safety and visibility during complex maneuvers.

Product Applications:

Our Autonomous Traction Machine is an invaluable asset for modernizing and expanding overhead power and communication infrastructure:

-

OPGW Stringing in Challenging Terrain: Ideal for deploying Optical Ground Wire over long spans, in mountainous regions, or areas where traditional equipment positioning is difficult, due to its self-moving capability.

-

Conductor Reconductoring Projects: Efficiently replaces aging or undersized power conductors, often simultaneously removing the old line and installing the new one, minimizing downtime.

-

Smart Grid Infrastructure Upgrades: Facilitates the rapid and precise installation of integrated communication (OPGW) and power lines necessary for advanced grid monitoring and control.

-

Power Line Uprating Projects: Supports the installation of higher capacity conductors to increase power transmission capabilities on existing corridors.

-

Urban & Suburban overhead line Works: Its self-moving feature allows for easier repositioning in congested areas, reducing traffic impact and setup time.

-

Live Line Operations (with proper safety protocols and accessories): Can be part of a system for hot line work where conductors or earthwires are changed or re-tensioned.

-

Any Complex Overhead Line Construction: Provides a versatile and efficient solution for projects requiring precise pulling/tensioning combined with enhanced mobility.

Technical Data Sheet (Example Specifications - please refer to specific model for exact data):

Note: Specific technical data will vary significantly depending on the model's pulling/tensioning capacity, engine power, and self-moving capabilities. Always refer to the detailed specification sheet for the particular model you are interested in. Proper training for operators and strict adherence to all safety guidelines are paramount during operation, especially concerning movement and high-tension forces.

Why Choose Ningbo Changshi Electric Power Machinery Manufacturing Limited?

Choosing Ningbo Changshi means partnering with a trusted industry leader dedicated to providing high-performance, precise, and safe equipment for your power line and electrical construction needs. Here’s why our Autonomous Traction Machine is your ideal choice:

-

Unmatched On-Site Mobility: The self-moving capability revolutionizes project logistics, accelerating setup, reducing manual labor, and enabling efficient operations in diverse and challenging terrains.

-

Integrated Efficiency: Seamlessly combine OPGW stringing with existing conductor replacement tasks into a single, high-performance machine, maximizing productivity and minimizing equipment footprint.

-

Precision & Protection: Advanced hydraulic control ensures the delicate handling of OPGW while providing robust power for OHTLstringingequipment.com/Conductor-Stringing-Equipment.html target='_blank'>conductor stringing, guaranteeing project quality and cable integrity.

-

Comprehensive One-Stop Supply Chain Mastery: As a preeminent manufacturer and exporter, we offer an unparalleled array of cutting-edge equipment for both overhead transmission line and underground cable laying projects, streamlining your entire procurement process with a single, reliable source for all your specialized tools.

-

Global Trust & Proven Excellence: Our unwavering commitment to quality, innovation, and safety has earned us the trust of leading power utilities and electrical contractors worldwide, making us the preferred choice for reliable, high-performance solutions that safeguard the future of communication and power infrastructure.

Final Summary:

Our Autonomous Traction Machine for OPGW Stringing & Conductor Replacement is a groundbreaking, self-moving solution meticulously engineered to provide superior efficiency and precision for complex overhead line upgrades. By combining powerful pulling/tensioning capabilities with independent mobility, it streamlines OPGW deployment and conductor replacement, setting a new standard for safety, speed, and cost-effectiveness in power infrastructure development. Trust Ningbo Changshi Electric Power Machinery Manufacturing Limited to provide the cutting-edge machinery fundamental to the success and innovation of your projects.

Transform your overhead line construction with unmatched efficiency and autonomy! Explore our Autonomous Traction Machines for OPGW stringing and conductor replacement. Visit