Anti-Twist Running Board for OPGW Stringing & Protection

Prevent twisting and damage to OPGW (Optical Ground Wire) during overhead stringing with Ningbo Changshi's specialized anti-twist running board, ensuring smooth, rotation-free cable installation.

- Transmission Line Wire Cable Conductor Tension Stringing Equipment

- Transmission Conductor Tension Stringing Equipment For Overhead Power Lines

- Tools For Power Lines,Substation,Electrical Construction & Maintenance

- Electric Power Transmission Distribution Line Construction Machine Tools

- Overhead Power Transmission Distribution Line Repair Hardware Fittings

- Underground Cable Laying Pulling Installation Equipment Machine Tools Accessories

- Information

- Video

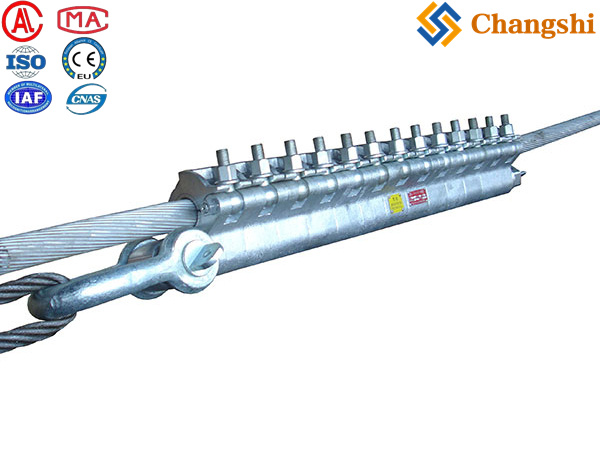

Anti-Twist Running Board: Essential for Kink-Free OPGW Stringing & Protection

At Ningbo Changshi Electric Power Machinery Manufacturing Limited, we recognize that the structural integrity and optical performance of OPGW (Optical Ground Wire) cables are highly susceptible to rotational forces, kinking, and twisting during overhead stringing operations. Even minor twisting can induce micro-bends in the optical fibers, leading to signal attenuation or complete data loss. Our Anti-Twist Running Board for OPGW Stringing & Protection is a highly specialized tool meticulously engineered to provide a stable, controlled, and rotation-free pathway specifically "used to OPGW construction." This "anti twist running board" acts as a critical interface, ensuring that the OPGW cable remains in its intended orientation as it passes across OHTLstringingequipment.com/Stringing-Blocks--Sheaves.html target='_blank'>Stringing Blocks and other suspension points, thereby safeguarding its delicate internal components from damaging rotational stress. As a prominent China manufacturer and exporter specializing in comprehensive one-stop supply for both overhead transmission line (OHTL) wire cable conductor tension stringing equipment and underground cable laying equipment, this anti-twist running board exemplifies our unwavering commitment to providing innovative, durable, and highly effective tools that ensure the long-term reliability and high performance of your crucial fiber optic and power transmission infrastructure.

The Anti-Twist Running Board features a unique design that actively prevents the OPGW cable from twisting as it is pulled. This is typically achieved through a combination of precision-engineered, multi-directional rollers or guide wheels that allow for linear movement while restricting rotational movement. Unlike standard running boards, its core function is to maintain the cable's longitudinal axis. The contact surfaces are smooth and non-abrasive, often made from specialized polymers or polished aluminum, to be gentle on the OPGW's outer jacket. It connects securely to the pulling line (e.g., pilot wire or synthetic rope) and the OPGW cable via a specialized Swivel, allowing the pulling force to be transmitted efficiently without inducing torque on the OPGW itself. By integrating Ningbo Changshi's Anti-Twist Running Board into your OPGW construction projects, you gain a critical advantage in protecting your valuable fiber optic assets, significantly reducing the risk of installation-induced damage, and ensuring the long-term optical performance and reliability of your integrated communication network.

Product Features & Benefits:

-

Active Twist Prevention: Engineered with specialized guiding mechanisms (e.g., multiple offset rollers or precision bearings) to actively prevent OPGW cable rotation and kinking during stringing, preserving optical fiber integrity.

-

Optimal OPGW Protection: Features smooth, non-abrasive contact surfaces and a stable design to prevent abrasion, crushing, or deformation of the sensitive OPGW outer jacket.

-

Smooth & Controlled Cable Passage: Facilitates seamless and controlled movement of the OPGW cable across Stringing Blocks and supports, even over long spans or uneven terrain.

-

Even Load Distribution: Acts as a secure interface between the pulling line and the OPGW, distributing pulling forces uniformly and preventing localized stress points.

-

High Strength & Durable Construction: Manufactured from robust, yet often lightweight, aluminum alloys or composite materials, ensuring reliable performance in demanding field conditions.

-

Corrosion Resistant: Materials and finishes are selected for superior resistance to outdoor elements, ensuring a long operational life.

-

Easy & Secure Connection: Designed for quick and safe attachment to the pulling line and OPGW cable, enhancing operational efficiency and safety.

-

Minimizes Costly Rework: By effectively preventing cable twisting and damage, it significantly reduces the need for expensive repairs, re-splicing, or re-stringing, saving time and resources.

-

Enhances Installation Quality: Ensures the OPGW cable is installed in its optimal, untwisted state, contributing to superior optical performance and longevity of the communication link.

Product Applications:

Our Anti-Twist Running Board for OPGW Stringing & Protection is an indispensable tool for all stages of OPGW cable installation:

-

OPGW Stringing: The primary application for ensuring the smooth, rotation-free pulling of Optical Ground Wire during new installations or reconductoring projects on overhead transmission lines.

-

Mid-Span Jointing/Splicing: Crucial for maintaining OPGW orientation and preventing twisting when pulling sections of cable for splicing operations.

-

Conductor Replacement with OPGW: Used in conjunction with other stringing equipment when replacing a traditional ground wire with an OPGW cable.

-

Complex Span Navigation: Particularly valuable in challenging terrains or long spans where controlling cable rotation is difficult.

-

Ensuring Optimal Optical Performance: Fundamental for preventing fiber damage that can degrade communication signal quality.

-

Any Project Where OPGW Integrity is Paramount: Applicable wherever OPGW cables need to be pulled, tensioned, or guided without inducing torsional stress.

Technical Data Sheet (Example Specifications - please refer to specific model for exact data):

Note: It is crucial to select the correct anti-twist running board size that is precisely compatible with the outer diameter of the OPGW cable being installed. Using an incorrectly sized board can lead to ineffective twist prevention or damage. Always verify the running board's Safe Working Load (SWL) against the expected pulling tension. Regularly inspect the rollers/guides and connection points for wear or damage before each use. Please contact us for detailed datasheets for specific models and their exact specifications, compatible OPGW diameters, and load capacities.

Why Choose Ningbo Changshi Electric Power Machinery Manufacturing Limited?

Choosing Ningbo Changshi means partnering with a trusted industry leader dedicated to providing high-performance, precise, and safe equipment for your power line and electrical construction needs. Here’s why our Anti-Twist Running Board for OPGW Stringing & Protection is your ideal choice:

-

Critical Twist Prevention: Our running boards are uniquely engineered to prevent damaging rotation and kinking of OPGW cables, safeguarding the integrity of your optical fibers and ensuring reliable communication.

-

Superior Cable Protection: Experience a smooth, non-abrasive passage that protects the sensitive outer jacket of OPGW, minimizing the risk of costly damage during stringing operations.

-

Enhanced Installation Quality: By maintaining the cable's proper orientation, our anti-twist running boards contribute directly to a higher quality installation, crucial for long-term optical performance.

-

Comprehensive One-Stop Supply Chain Mastery: As a preeminent manufacturer and exporter, we offer an unparalleled array of cutting-edge equipment for both overhead transmission line and underground cable laying projects, streamlining your entire procurement process with a single, reliable source for all your specialized tools.

-

Global Trust & Proven Excellence: Our unwavering commitment to quality, innovation, and safety has earned us the trust of leading power utilities and electrical contractors worldwide, making us the preferred choice for reliable, high-performance tools that safeguard the future of communication and power infrastructure.

Final Summary:

Our Anti-Twist Running Board for OPGW Stringing & Protection is an indispensable, meticulously engineered tool designed for the safe, smooth, and rotation-free passage of OPGW (Optical Ground Wire) cables during overhead stringing operations. Its specialized design actively prevents twisting and kinking, which is fundamental to preserving the integrity and performance of your critical fiber optic communication infrastructure. Trust Ningbo Changshi Electric Power Machinery Manufacturing Limited to provide the cutting-edge accessories essential for the success and safety of your complex OPGW construction projects.

Ensure kink-free and damage-free OPGW installation! Explore our Anti-Twist Running Boards for superior cable protection. Visit