2500kN High-Force Hydraulic Compressor for Large Conductors & EHV/UHV Terminals

Achieve uncompromising connections on massive conductors and EHV/UHV terminals with Ningbo Changshi's 2500kN (250-ton) hydraulic compressor. Engineered for extreme power line applications.

- Transmission Line Wire Cable Conductor Tension Stringing Equipment

- Transmission Conductor Tension Stringing Equipment For Overhead Power Lines

- Tools For Power Lines,Substation,Electrical Construction & Maintenance

- Electric Power Transmission Distribution Line Construction Machine Tools

- Overhead Power Transmission Distribution Line Repair Hardware Fittings

- Underground Cable Laying Pulling Installation Equipment Machine Tools Accessories

- Information

- Video

2500kN High-Force Hydraulic Compressor: Unrivaled Power for the Toughest Conductor & Terminal Connections in EHV/UHV Systems

At Ningbo Changshi Electric Power Machinery Manufacturing Limited, we understand that the increasing current capacities and extreme mechanical stresses of modern Extra-High Voltage (EHV) and Ultra-High Voltage (UHV) transmission lines demand connection solutions of unprecedented power and precision. Our 2500kN High-Force Hydraulic Compressor for Large Conductors & EHV/UHV Terminals is the pinnacle of conductor compression technology, specifically engineered to deliver an immense 2500 kilonewtons (equivalent to 250 tons) of force. This formidable power ensures flawless, high-integrity "cold weld" connections on the largest conductors, heaviest earthwires, and most critical bi-metallic (Cupreous-aluminous) terminals found in the most demanding power infrastructure projects globally. As a prominent China manufacturer and exporter specializing in comprehensive one-stop supply for both overhead transmission line (OHTL) wire cable conductor tension stringing equipment and underground cable laying equipment, this powerful hydraulic compressor exemplifies our unwavering commitment to providing innovative, supremely durable, and highly effective equipment that ensures superior safety, efficiency, and the long-term, unyielding performance of your most vital electrical connections.

This 2500kN Hydraulic Compressor is designed for applications where standard hydraulic crimpers simply cannot deliver the necessary force or accommodate the sheer size of the components. Its colossal compression capability ensures a perfect, void-free connection across the entire crimp area, even on conductors with very large cross-sectional areas or rigid strand configurations common in EHV/UHV applications. This immense, controlled hydraulic pressure is critical for achieving optimal metal flow and molecular bonding, resulting in connections with minimal electrical resistance, maximum current carrying capacity, and exceptional mechanical strength – often exceeding the breaking strength of the conductor itself. The tool's versatility extends to compressing specialized terminals on large overhead conductors (e.g., multi-bundle ACSR, ACAR), heavy-gauge earthwires (including OPGW), and particularly challenging cupreous-aluminous (bi-metallic) terminals that facilitate a robust, corrosion-resistant transition between dissimilar metals in high-current applications. Investing in this high-force compressor is paramount for utilities and contractors involved in constructing and maintaining large-scale power infrastructure, where connection integrity is non-negotiable for system reliability and safety.

Product Features & Benefits:

-

Extreme 2500kN (250 Ton) Compression Force: Delivers unparalleled force for flawlessly crimping the largest conductors, heavy-duty earthwires, and specialized EHV/UHV terminals, ensuring optimal electrical and mechanical integrity.

-

Engineered for Large Conductors & EHV/UHV Applications: Specifically designed to handle the massive cross-sectional areas and robust construction of conductors and terminals typically found in Ultra-High Voltage (UHV) and Extra-High Voltage (EHV) systems.

-

Superior Connection Quality: Ensures uniform, high-density compression across the entire joint, eliminating voids, minimizing electrical resistance, preventing hotspots, and maximizing current carrying capacity and connection lifespan.

-

Versatile Material Compatibility: Capable of precisely compressing connectors on:

-

Large Overhead Conductors: Multi-bundle ACSR, ACAR, AAC, and high-capacity aluminum alloys.

-

Heavy-Duty Earthwires: For robust grounding and overhead ground wire (OPGW) installations.

-

Critical Bi-Metallic (Cupreous-Aluminous) Terminals: For secure, corrosion-resistant transitions between large copper and aluminum conductors.

-

-

Robust & Industrial-Grade Construction: Built with heavy-duty, high-strength forged steel and precision-machined components to withstand continuous, high-force operations in the most demanding field environments.

-

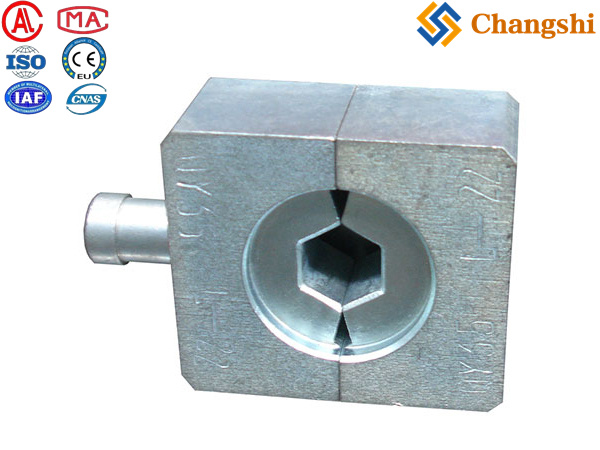

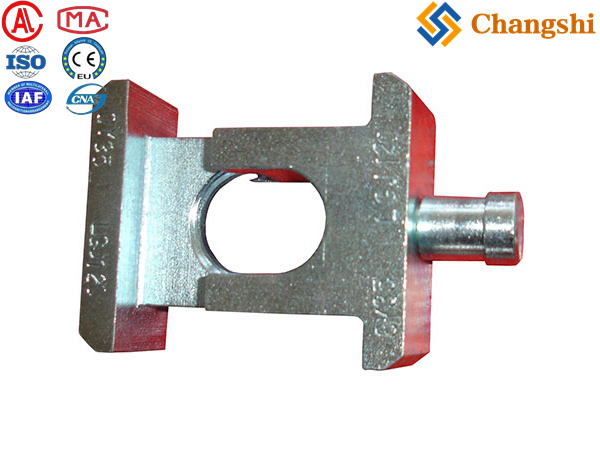

Precision Die Compatibility: Utilizes a range of specialized, high-capacity interchangeable dies (often hexagonal or round, sold separately) designed for the largest conductor and terminal sizes, ensuring exact, repeatable crimps.

-

Enhanced Safety & Control: Features integrated safety pressure relief valves, a robust design to prevent kickback, and typically operates with a remote hydraulic pump for controlled force application and operator safety.

-

Long-Term Reliability: The sheer power and robust construction minimize wear and tear, providing exceptional durability and a long, reliable service life for critical projects.

Product Applications:

Our 2500kN High-Force Hydraulic Compressor is an indispensable tool for the most demanding electrical construction and maintenance tasks in large-scale power infrastructure:

-

Ultra-High Voltage (UHV) & Extra-High Voltage (EHV) Transmission Line Projects: Essential for crimping large diameter, multi-bundle conductors (e.g., 600mm² to 2500mm² and above) and their associated full-tension splices, dead-ends, and repair sleeves.

-

Major Substation Construction & Expansion: For securely crimping large-scale busbar connectors, high-capacity switchgear terminals, and primary equipment connections.

-

Heavy-Duty Earthwire (OPGW) Installations: For critical, high-strength connections on large optical ground wire bundles that serve as both grounding and fiber optic communication lines.

-

Large Industrial & Commercial Electrical Connections: Wherever very large cross-sectional area conductors (e.g., for smelters, data centers, heavy manufacturing) require robust crimped connections.

-

Large Bi-Metallic Terminal Applications: For creating secure, durable, and corrosion-resistant transitions between massive copper and aluminum conductors or busbars using large cupreous-aluminous connectors.

-

Specialized overhead line Repair & Upgrade: For major repair work or capacity upgrades on existing heavy-duty transmission lines.

Technical Data Sheet:

Note: The selection and operation of a 2500kN hydraulic compressor require expert knowledge. Always use the correct die set that precisely matches the conductor size and type of compression connector. Adherence to manufacturer's specifications for number of crimps, and all applicable safety guidelines for high-pressure hydraulic equipment and large-scale electrical work is absolutely mandatory. Extensive training for operators is essential. Please contact us for detailed datasheets for specific models, compatible die sets, and recommended hydraulic pump units to match your exact heavy-duty application requirements.

Why Choose Ningbo Changshi Electric Power Machinery Manufacturing Limited?

Choosing Ningbo Changshi means partnering with a trusted industry leader dedicated to providing the most powerful, precise, and robust solutions for your critical high-voltage power infrastructure projects. Here’s why our 2500kN High-Force Hydraulic Compressor is your ultimate choice:

-

Unmatched Power for Extreme Applications: With an astounding 2500kN (250 tons) of force, this compressor is engineered to deliver uncompromising, high-integrity connections on the largest conductors and terminals, ensuring reliability for EHV/UHV systems.

-

Superior Connection Performance: Guarantees optimal electrical conductivity, minimal resistance, and exceptional mechanical strength, essential for preventing failures, reducing energy losses, and maximizing the lifespan of your critical power connections.

-

Comprehensive One-Stop Supply Chain Mastery: As a preeminent manufacturer and exporter, we offer an unparalleled array of cutting-edge equipment for both overhead and underground power line projects, streamlining your entire procurement process with a single, reliable source for all your specialized heavy-duty connection and operational needs.

-

Engineered for Durability & Reliability: Constructed from robust, high-grade materials with precision engineering, our 2500kN compressor is built to withstand the most demanding field conditions and deliver consistent, reliable performance for decades, protecting your significant investment.

-

Global Trust & Proven Excellence: Our unwavering commitment to quality, innovation, and safety has earned us the trust of leading power utilities and electrical contractors worldwide, making us the undisputed choice for the most powerful and dependable connection tools in the industry.

Final Summary:

Our 2500kN High-Force Hydraulic Compressor is an indispensable, meticulously engineered solution designed to create flawless, high-integrity connections on the largest conductors and EHV/UHV terminals. Delivering an astounding 250 tons of compression force, it ensures superior electrical performance, mechanical strength, and long-term reliability for the most critical power infrastructure. Trust Ningbo Changshi Electric Power Machinery Manufacturing Limited to equip your teams with the highest-quality, most powerful, and intelligently designed connection tools that are fundamental to the safety and resilience of your power grid.

Master the toughest conductor connections on your EHV/UHV projects! Explore our 2500kN High-Force Hydraulic Compressors. Visit