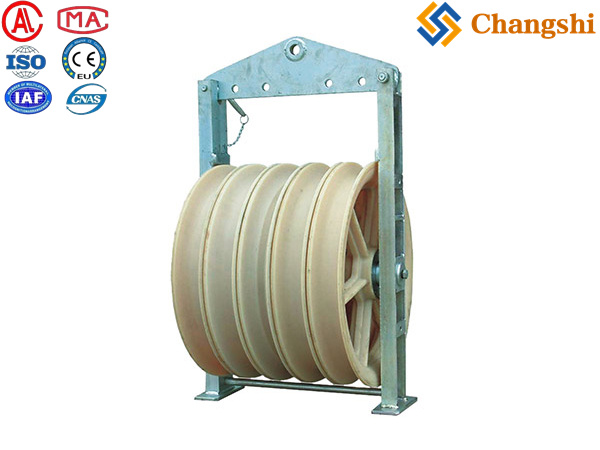

Power Transmission Line Stringing Equipment Nylon Wheel Stringing Pulley Block

The Power Transmission Line Stringing Equipment Nylon Wheel Stringing Pulley Block is a crucial tool used in overhead power line construction for stringing conductors, OPGW, ADSS, and communication lines. These pulley blocks are designed to support and guide cables during installation, minimizing friction and preventing cable damage.

- Transmission Line Wire Cable Conductor Tension Stringing Equipment

- Transmission Conductor Tension Stringing Equipment For Overhead Power Lines

- Tools For Power Lines,Substation,Electrical Construction & Maintenance

- Electric Power Transmission Distribution Line Construction Machine Tools

- Overhead Power Transmission Distribution Line Repair Hardware Fittings

- Underground Cable Laying Pulling Installation Equipment Machine Tools Accessories

- Information

- Video

The power transmission line stringing Equipment Nylon Wheel Stringing Pulley Block is a crucial tool used in overhead power line construction for stringing conductors, OPGW, ADSS, and communication lines. These pulley blocks are designed to support and guide cables during installation, minimizing friction and preventing cable damage.

-

: High-strength MC nylon wheels combined with a galvanized steel frame for durability and corrosion resistance.

-

: Usually multi-wheel (single, three, or five wheels) configurations to accommodate different conductor bundles.

-

: Range from small (120 mm diameter) to large (up to 1040 mm diameter) depending on the conductor size and application.

-

: Typically from 5 kN to 110 kN, suitable for various conductor sizes up to 1000 mm².

-

: Varies by model; for example, a three-wheel pulley block with 1040 mm diameter wheels weighs about 210 kg.

-

: Used for stringing overhead transmission lines, including single and bundled conductors, OPGW, and ADSS cables.

-

: Some models come with rubber-covered wheels to reduce wear and noise; lateral wheels are often mounted on ball bearings for smooth rotation.

-

: Pulley blocks can be manufactured to customer specifications for different sizes and loads.

-

| Model | Wheel Diameter × Width (mm) | Conductor Size (mm²) | Rated Load (kN) | Weight (kg) | Wheel Material |

|---|---|---|---|---|---|

| SHDN-120X30 | 120 × 30 | 25–70 | 5 | 1.5 | Nylon |

| SHDN-200X40 | 200 × 40 | 150–240 | 15 | 2.5 | Nylon |

| SHDN-320X60 | 320 × 60 | 300–400 | 20 | 7.5 | Nylon |

| SHDN-660X100 | 660 × 100 | ≤500 | 20 | 20 | Nylon |

| SHDN-1040X125 | 1040 × 125 | ≤1000 | 55 | 105 | Nylon |

-

: Nylon wheels reduce the overall weight compared to metal wheels, making handling easier.

-

: Nylon material protects the cable surface, reducing wear during stringing.

-

: Galvanized steel frames resist corrosion in outdoor environments.

-

: Suitable for various conductor types and sizes, including fiber optic cables.

These pulley blocks are installed on stringing equipment to support and guide cables as they are pulled through towers and sheaves during transmission line construction. Their design ensures smooth cable movement, reduces mechanical stress on cables, and improves installation efficiency.

This equipment is widely used globally in power transmission projects and is available from manufacturers offering high-quality, ISO/CE-certified products with warranty and customization options