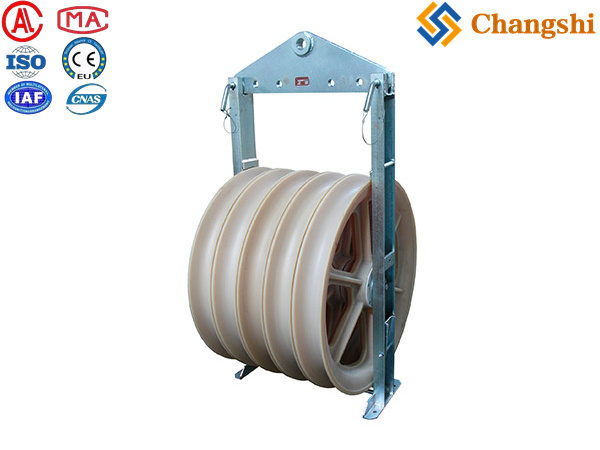

Helicopter Stringing Wire Rope Cable Pulley Block for power transmission lines

A Helicopter Stringing Wire Rope Cable Pulley Block is a specialized pulley block designed for overhead power transmission line construction, where a helicopter is used to string pilot ropes or conductors between towers. These blocks guide and support the wire rope or conductor while ensuring safety and efficiency during aerial stringing operations.

- Transmission Line Wire Cable Conductor Tension Stringing Equipment

- Transmission Conductor Tension Stringing Equipment For Overhead Power Lines

- Tools For Power Lines,Substation,Electrical Construction & Maintenance

- Electric Power Transmission Distribution Line Construction Machine Tools

- Overhead Power Transmission Distribution Line Repair Hardware Fittings

- Underground Cable Laying Pulling Installation Equipment Machine Tools Accessories

- Information

- Video

A Helicopter Stringing Wire Rope Cable Pulley Block is a specialized pulley block designed for overhead power transmission line construction, where a helicopter is used to string pilot ropes or conductors between towers. These blocks guide and support the wire rope or conductor while ensuring safety and efficiency during aerial stringing operations.

-

: Typically made from aluminum alloy or high-strength nylon (MC Nylon), with grooves lined by neoprene or rubber to reduce conductor wear and friction.

-

: Common diameters include 508 mm, 660 mm, 750 mm, 822 mm, 916 mm, and 1040 mm, chosen based on conductor size and application.

-

: Available with 1, 3, or 5 sheaves to accommodate single or bundled conductors (e.g., two or four bundle conductors).

-

: Rated working loads range from about 5 kN up to 105 kN or more, depending on model and number of sheaves.

-

: Made from galvanized steel for durability and corrosion resistance.

-

: Sheaves are mounted on ball bearings for smooth rotation, reducing friction during stringing.

-

: Designed to ensure correct positioning of the rope or conductor during helicopter stringing, preventing misalignment or damage.

-

: Some models include grounding devices or conductive sheaves to protect against electrical hazards.

-

: Varies widely, from around 2 kg for small single-sheave blocks up to 200+ kg for large multi-sheave blocks.

-

-

Used to string pilot ropes and conductors on overhead transmission lines, especially in difficult terrain where helicopter assistance is necessary.

-

Suitable for stringing single conductors or multiple bundled conductors.

-

Helps reduce conductor damage and improves safety during aerial stringing operations.

| Model | Sheave Diameter (mm) | Number of Sheaves | Rated Load (kN) | Suitable Conductor Size (ACSR mm²) | Weight (kg) | Sheave Material |

|---|---|---|---|---|---|---|

| SHDZ-160x40 | 160 | 1 | 10 | 70-95 | 3.2 | Aluminum alloy |

| SHDZ660 | 660 | 1 | 20 | 400-500 | 30 | Rubber lined aluminum |

| SHDNZ508 | 508 | 1 | 20 | 300-400 | 16 | Nylon (rubber lined) |

| SH3Z508 | 508 | 3 | 40 | 300-400 | 61 | Central steel or nylon; sides aluminum lined with neoprene |

| SH3ZLN822 | 822 | 3 | 60 | 500-700 | 128 | Nylon lined with neoprene |

| SH5WQNZ660 | 660 | 5 | 50-180 | Various | 61-320 | MC Nylon / Aluminum alloy |

Helicopter OHTLstringingequipment.com/Stringing-Blocks--Sheaves.html target='_blank'>Stringing Blocks are essential tools for aerial conductor and pilot rope installation in overhead power transmission projects. Their design focuses on minimizing conductor damage, ensuring correct rope positioning, and providing electrical grounding options. They come in various sizes and configurations to suit different conductor bundles and stringing requirements, with durable construction and smooth operation enabled by ball-bearing-mounted sheaves.

These blocks are widely used worldwide and comply with ISO and CE certifications, ensuring quality and safety in demanding field conditions.