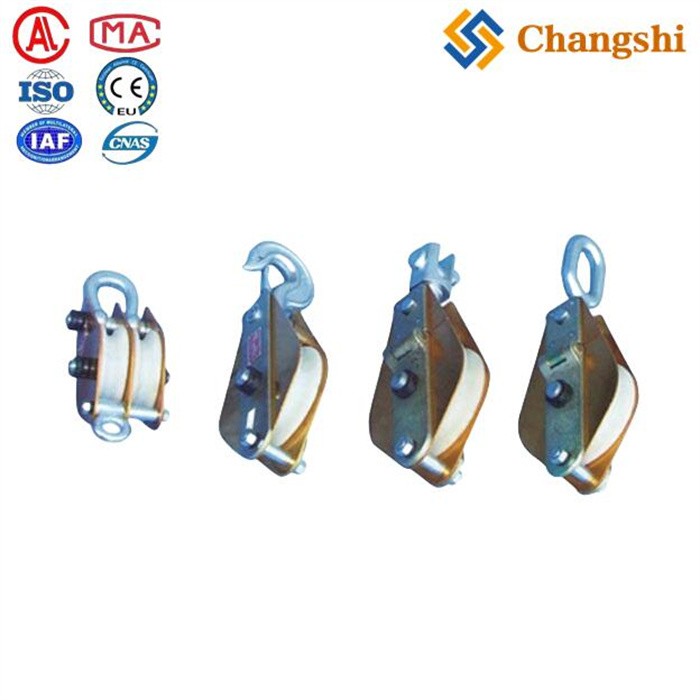

Aluminum Alloy Nylon Sheave Hoisting Tackle Lifting Pulley Block for power lines

An Aluminum Alloy and MC Nylon Sheave Hoisting Tackle is a lightweight, durable pulley block used primarily in overhead power transmission line construction and other lifting operations. It combines an aluminum alloy side panel with an MC nylon sheave (pulley wheel), offering a balance of strength, corrosion resistance, and reduced weight for easier handling in the field.

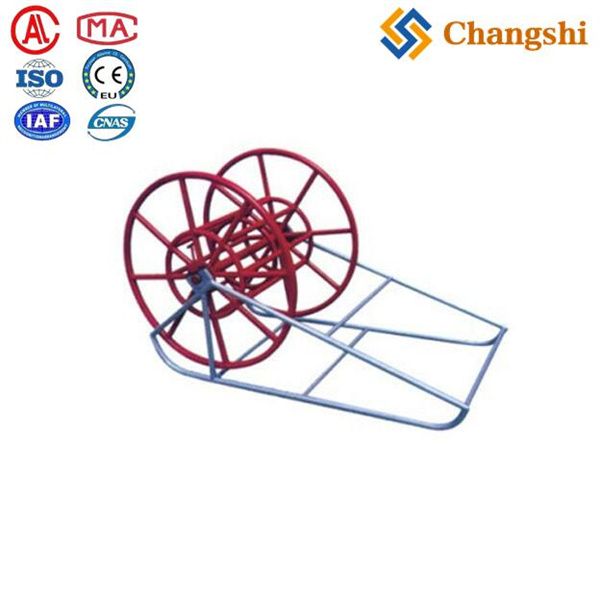

- Transmission Line Wire Cable Conductor Tension Stringing Equipment

- Transmission Conductor Tension Stringing Equipment For Overhead Power Lines

- Tools For Power Lines,Substation,Electrical Construction & Maintenance

- Electric Power Transmission Distribution Line Construction Machine Tools

- Overhead Power Transmission Distribution Line Repair Hardware Fittings

- Underground Cable Laying Pulling Installation Equipment Machine Tools Accessories

- Information

- Video

An Aluminum Alloy and MC Nylon Sheave Hoisting Tackle is a lightweight, durable pulley block used primarily in overhead power transmission line construction and other lifting operations. It combines an aluminum alloy side panel with an MC nylon sheave (pulley wheel), offering a balance of strength, corrosion resistance, and reduced weight for easier handling in the field.

-

: Aluminum alloy side plates for strength and corrosion resistance; MC nylon sheaves for smooth operation, low friction, and conductor protection.

-

: Typically open type with a hook or ring hoisting point, allowing easy assembly and disassembly of steel wire ropes.

-

: The use of aluminum and nylon significantly reduces dead weight compared to all-steel blocks, facilitating easier transport and installation.

-

: Commonly available with rated loads from 10 kN up to 150 kN (approximately 1 to 15 tons).

-

: Sheave diameters range from about 80 mm to 280 mm or more, designed to accommodate rope diameters from 6 mm up to 21.5 mm depending on the model.

-

: Available in single, double, triple, and even four-sheave configurations to suit different lifting and rigging needs.

-

: Used for lifting heavy objects, erecting towers, stringing conductors, and other hoisting operations in line construction and industrial settings.

-

: Products typically comply with ISO 9001:2008 quality standards and come with warranties and after-sales support.

-

| Model | Number of Sheaves | Rated Load (kN) | Sheave Diameter × Width (mm) | Rope Diameter (mm) | Weight (kg) | Hoisting Point Type |

|---|---|---|---|---|---|---|

| QHN1-1K | 1 | 10 | 100 × 31 | 7.7 | 1.8 | Hook (G), Ring (H) |

| QHN2-2 | 2 | 20 | 100 × 31 | 7.7 | 2.6 | Hook (G), Ring (H) |

| QHN3-3 | 3 | 30 | 100 × 31 | 7.7 | 4.6 | Hook (G), Ring (H) |

| QHN5-1K | 1 | 50 | 166 × 40 | 13 | 5.2 | Hook (G), Ring (H) |

| QHN8-1K | 1 | 80 | 205 × 49 | 17 | 7.2 | Hook (G), Ring (H) |

| QHN15-4 | 4 | 150 | 150 × 39 | 11 | 13.9 | Hook (H) |

-

: Easier to handle on site compared to traditional steel pulley blocks.

-

: Aluminum alloy and nylon resist rust and environmental degradation.

-

: MC nylon sheaves reduce friction and wear on ropes and conductors.

-

: Suitable for a wide range of lifting and stringing tasks in power line construction.

-

-

Widely used in transmission line construction for lifting equipment, hoisting conductors, and tower erection.

-

Compatible with various rigging setups due to multiple hoisting point types (hook or ring).

-

Often supplied with OEM quality assurance and international certifications.

, Aluminum Alloy and MC Nylon Sheave Hoisting Tackles are lightweight, durable, and efficient pulley blocks ideal for lifting and stringing operations in overhead power line construction, combining corrosion resistance and smooth rope handling with a range of load capacities and configurations to meet diverse field requirements.