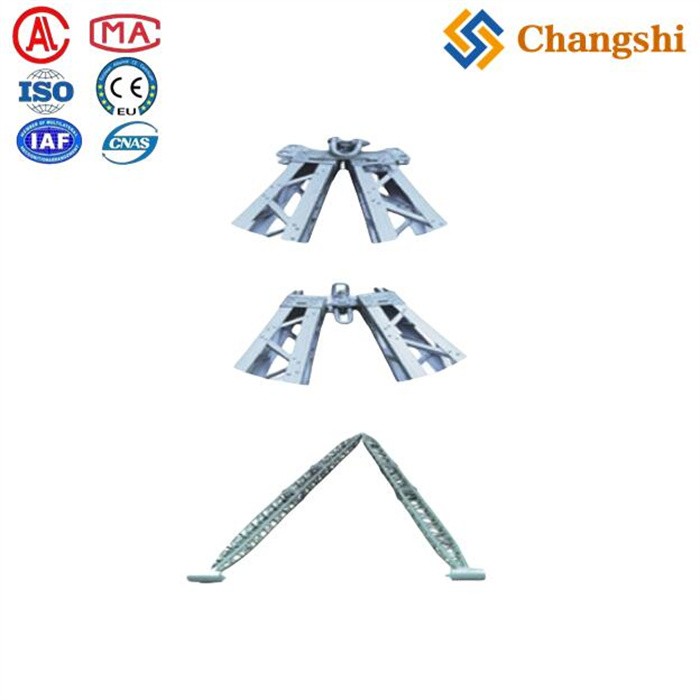

Aluminum Alloy A-Shape Lattice Gin Pole For Transmission And Distribution Line Construction

An Aluminum Alloy A-Shape Lattice Gin Pole is a specialized tool used primarily in transmission and distribution line construction for erecting small poles or hoisting moderate weight components. It features a lattice structure in an A-shape design made from high-strength aluminum alloy, often combined with galvanized steel parts for durability and corrosion resistance.

- Transmission Line Wire Cable Conductor Tension Stringing Equipment

- Transmission Conductor Tension Stringing Equipment For Overhead Power Lines

- Tools For Power Lines,Substation,Electrical Construction & Maintenance

- Electric Power Transmission Distribution Line Construction Machine Tools

- Overhead Power Transmission Distribution Line Repair Hardware Fittings

- Underground Cable Laying Pulling Installation Equipment Machine Tools Accessories

- Information

- Video

An Aluminum Alloy A-Shape Lattice Gin Pole is a specialized tool used primarily in transmission and distribution line construction for erecting small poles or hoisting moderate weight components. It features a lattice structure in an A-shape design made from high-strength aluminum alloy, often combined with galvanized steel parts for durability and corrosion resistance.

-

: The gin pole has an A-shaped lattice frame, which provides strength and stability while being lightweight. The lattice design typically uses right-angle aluminum titanium alloy sections joined by rivets or tubular aluminum alloy sections. The head of the gin pole can be configured in different styles, including upending, fixed, or upending-fixed types, often equipped with a tri-pulley system for wire handling.

-

: Made from high-strength aluminum alloy, sometimes specified as angle aluminum alloy or tubular aluminum alloy, ensuring portability, durability, and resistance to environmental factors. Steel components are usually galvanized to prevent rust.

-

: The safety factor is generally around 2.5, indicating a robust design suitable for the safety requirements of overhead line work.

-

: Allowable vertical loads vary by model and size, ranging from approximately 18 kN to over 100 kN depending on the gin pole length and design. For example, some models support vertical loads up to 72 kN with weights around 10.5 kg/m, while larger models can handle higher loads with corresponding increases in weight.

-

: Many models are designed to work with manual hand crank winches with a maximum output force of about 5 kN. The recommended wire rope is typically 7 mm in diameter, with a workable length up to nine times the gin pole length.

-

: Mainly used for setting up small single poles or lifting components in transmission and distribution line construction. The gin pole's single-arm style allows freedom of direction and ease of use in the field.

-

| Model | Length (m) | Base Stroke (m) | Allowable Vertical Load (kN) | Weight (kg/m) | Notes |

|---|---|---|---|---|---|

| LBR250-8 | 8 | 2.8 | 72 | 10.5 | Lattice A-shape, aluminum alloy |

| LBGR120J-6 | 2.1 | 2.1 | 30 | 7.5 | Tubular aluminum alloy, tri-pulley |

| LBGR150J-8 | 2.8 | 2.8 | 31 | 8 | Tubular aluminum alloy |

| LBR400-14B | 4.9 | 4.9 | 98 | 16.5 | Larger lattice gin pole |

These examples illustrate the range of sizes and capacities available, suitable for different scales of transmission line work.

-

These gin poles often come with certifications such as CE, ISO, and RoHS, ensuring compliance with international quality and safety standards.

-

Manufacturers typically conduct 100% testing before shipment to guarantee product quality and reliability.

-

The Aluminum Alloy A-Shape Lattice Gin Pole is a lightweight, durable, and versatile tool designed for overhead line construction, particularly for erecting small poles and lifting moderate loads. Its lattice A-shape structure made from high-strength aluminum alloy provides an excellent balance of strength and portability. With a safety factor of around 2.5 and compatibility with manual winches, it is a reliable choice for transmission and distribution line engineers.

This equipment is customizable in terms of length, head style, and load capacity to meet specific project requirements, backed by certifications and quality assurance from manufacturers.