Splicing Sleeve Straightener for Crimped Conductors

ur splicing sleeve straightener is a professional tool for correcting bent or deformed crimped splicing sleeves. It ensures a smooth profile that can pass safely through stringing blocks and rollers, protecting the conductor and the splice from damage.

- Transmission Line Wire Cable Conductor Tension Stringing Equipment

- Transmission Conductor Tension Stringing Equipment For Overhead Power Lines

- Tools For Power Lines,Substation,Electrical Construction & Maintenance

- Electric Power Transmission Distribution Line Construction Machine Tools

- Overhead Power Transmission Distribution Line Repair Hardware Fittings

- Underground Cable Laying Pulling Installation Equipment Machine Tools Accessories

- Information

- Video

Splicing Sleeve Straightener: The Finishing Tool for Flawless Conductor Connections

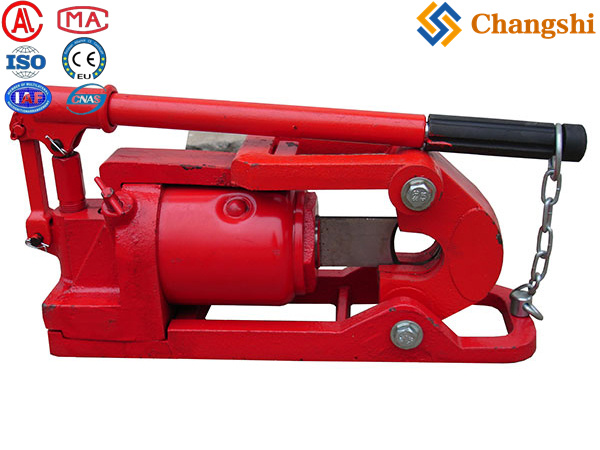

As a prominent China manufacturer and exporter, Ningbo Changshi Electric Power Machinery Manufacturing Limited is dedicated to providing specialized tools that meet the precise and demanding needs of the power line industry. The Splicing Sleeve Straightener is a perfect example of this. This indispensable accessory is designed for a critical final step in overhead transmission line (OHTL) construction: to "straighten the bent splicing sleeves" after they have been fully crimped. While a properly crimped sleeve creates a strong mechanical and electrical bond, the process can sometimes leave the sleeve with a slightly bent or uneven profile. Our splicing sleeve straightener is a professional-grade finishing tool that corrects this, ensuring the final splice is perfectly straight and has a smooth profile. This is crucial for preventing the splice from snagging on OHTLstringingequipment.com/Stringing-Blocks--Sheaves.html target='_blank'>Stringing Blocks or rollers, which could damage the splice or the conductor.

Our splicing sleeve straightener is meticulously constructed from high-strength, durable materials, guaranteeing a long service life and reliable performance in the field. Its specialized design applies targeted force to the crimped sleeve, gently and effectively straightening it to its optimal form. By incorporating this tool into your workflow, you are not only ensuring the mechanical integrity of the splice but also enhancing the efficiency and safety of the entire stringing process. This professional-grade accessory is a must-have for technicians who understand that every detail, no matter how small, is critical to the safety and longevity of the power line.

Product Features & Benefits:

-

Corrects Bent Sleeves: The primary benefit is its ability to effectively straighten bent or deformed splicing sleeves after crimping, ensuring a smooth and uniform profile.

-

Prevents Damage During Stringing: By ensuring a straight profile, the tool helps the splice pass smoothly through Stringing Blocks and tensioning wheels, preventing snags that could damage the conductor or the sleeve itself.

-

Enhances Splice Integrity: A straight sleeve is less prone to stress concentrations and fatigue, contributing to the long-term reliability and integrity of the electrical connection.

-

Durable & Robust Construction: Built with high-strength materials, the straightener is designed to withstand the rigors of field use and deliver consistent performance for years.

-

Streamlines Workflow: The use of this tool for a final quality check helps to streamline the overall stringing process by preventing potential issues down the line.

Product Applications:

The splicing sleeve straightener is an essential accessory for:

-

overhead line Construction & Stringing: The primary application for a final quality check after crimping a splicing sleeve, before the conductor is pulled under tension.

-

Splicing of Conductors: Ideal for any project involving the splicing of high-voltage conductors, where the quality and profile of the finished splice are critical.

-

Conductor Repair & Maintenance: A valuable tool for on-site repairs and maintenance, ensuring that any new splice is perfectly formed and ready for service.

-

General Electrical Construction: A critical component for any overhead line project that requires the highest standards of quality and safety for all connections.

Technical Data Sheet:

Why Choose Ningbo Changshi for Your Stringing Equipment?

Choosing Ningbo Changshi means partnering with an industry leader who is committed to providing a comprehensive suite of high-quality tools and equipment. Our splicing sleeve straightener is a prime example of our dedication to providing specialized, innovative solutions that ensure the safety, efficiency, and integrity of your projects. As your one-stop supplier, we provide not just the primary tools, but all the essential finishing accessories for a complete and flawless operation.

Final Summary

The Splicing Sleeve Straightener is the definitive solution for achieving safe, durable, and exceptionally reliable conductor connections by ensuring the final crimped splice has the perfect profile. Its specialized design and robust construction make it an indispensable tool for streamlining your overhead line construction, maintenance, and repair operations with superior reliability and performance.

Ensure the integrity and safety of your conductor splices from start to finish. Learn more about our Splicing Sleeve Straightener and how it can benefit your projects. Contact Ningbo Changshi Electric Power Machinery Manufacturing Limited today to request a detailed quotation and technical specifications tailored to your specific needs!