Duty Steel Swivel Frame Gin Pole for Extreme Load Lifting

Master heavy and complex lifts with Ningbo Changshi's robust steel swivel frame gin pole. Engineered for extreme loads and multi-directional precision in overhead line and substation construction.

- Transmission Line Wire Cable Conductor Tension Stringing Equipment

- Transmission Conductor Tension Stringing Equipment For Overhead Power Lines

- Tools For Power Lines,Substation,Electrical Construction & Maintenance

- Electric Power Transmission Distribution Line Construction Machine Tools

- Overhead Power Transmission Distribution Line Repair Hardware Fittings

- Underground Cable Laying Pulling Installation Equipment Machine Tools Accessories

- Information

- Video

Heavy-Duty Steel Swivel Frame Gin Pole: Unmatched Strength and Dynamic Control for Extreme Electrical Infrastructure Lifts

At Ningbo Changshi Electric Power Machinery Manufacturing Limited, we understand that the most challenging and massive lifting operations in overhead transmission line (OHTL) and substation construction demand equipment of unparalleled strength, stability, and dynamic precision. Our Heavy-Duty Steel Swivel Frame Gin Pole is the ultimate robust lifting solution, meticulously engineered from high-strength structural steel and featuring a comprehensive "frame" design combined with a versatile "swivel" head for multi-directional load handling. As a prominent China manufacturer and exporter specializing in comprehensive one-stop supply for both overhead transmission line (OHTL) wire cable conductor tension stringing equipment and underground cable laying equipment, this formidable steel swivel gin pole exemplifies our unwavering commitment to providing innovative, durable, and highly effective equipment that ensures superior productivity, absolute safety, and pinpoint operational precision on your most critical and demanding infrastructure developments worldwide.

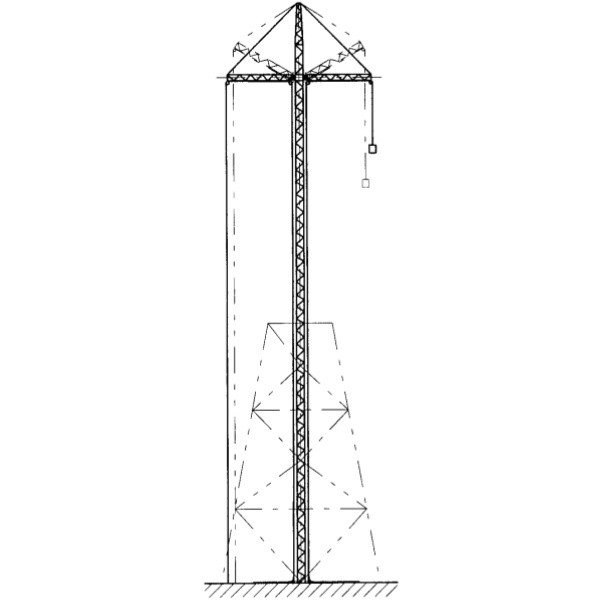

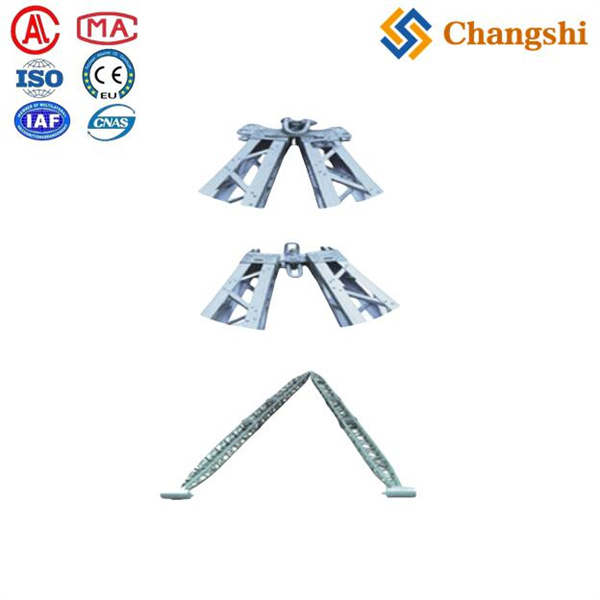

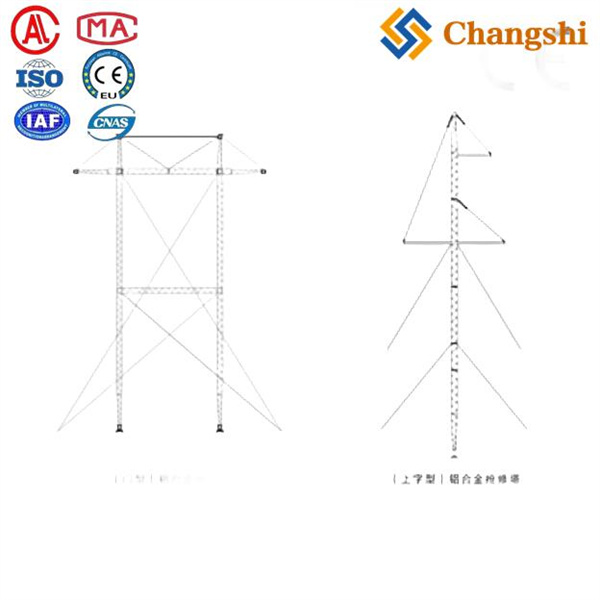

The Steel Swivel Frame Gin Pole is distinguished by its formidable construction from high-grade structural steel, which provides maximum load-bearing capacity and resilience under extreme conditions. The "frame" design typically indicates a more substantial, often multi-column or lattice-like base and main structure, offering enhanced rigidity and stability compared to single-mast poles, specifically built to handle the heaviest conceivable loads. The critical "swivel" capability at the gin pole's head allows for full 360-degree rotation of the lifting point even under load. This dynamic feature empowers operators to precisely orient, pull, and place massive components from various angles without needing to re-rig or reposition the entire gin pole, significantly streamlining complex maneuvers. Whether you are lifting the largest multi-bundle UHV conductors, installing colossal power transformers and reactors, setting immense lattice tower sections, or handling other super-heavy and oversized electrical components, this system provides the ultimate combination of raw power, exceptional stability, and fluid, controlled movement. It is an indispensable asset for maximizing efficiency, ensuring the highest level of safety, and achieving impeccable accuracy in the most ambitious OHTL stringing, structure erection, and equipment installation projects.

Product Features & Benefits:

-

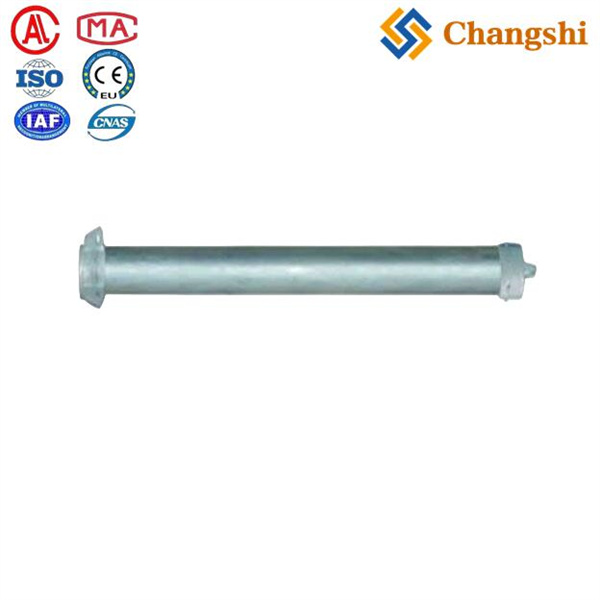

Extreme Load Capacity (Steel Construction): Built from high-strength structural steel, providing the absolute maximum load-bearing capability for the heaviest conductors, largest equipment, and most massive structural components.

-

Dynamic Multi-Directional Swivel Head: Features a robust, integrated swivel mechanism at the top, allowing the lifting point to rotate 360 degrees under full load, enabling precise angular pulling, positioning, and controlled load orientation in any direction.

-

Superior Stability (Frame Design): The reinforced "frame" construction provides exceptional lateral stability, rigidity, and superior load distribution, making it incredibly robust and reliable for extreme or highly dynamic lifts.

-

Enhanced Precision & Control: The combination of ultimate stability, rotational capability, and robust construction ensures unparalleled control over the load's movement, virtually eliminating swing and deflection, crucial for accurate and safe placement.

-

Unmatched Durability & Longevity: Steel construction offers supreme resistance to impact, abrasion, and fatigue, ensuring an extended service life in the harshest industrial and construction environments.

-

Customizable Heights & Configurations: Often designed in modular or sectional components, allowing for tailored heights and base configurations to suit highly specific project requirements and lifting scenarios.

-

Optimized for Complex Rigging: The swivel feature significantly simplifies rigging setups for multi-directional pulls, saving time, reducing labor, and enhancing safety on intricate projects.

-

Safety Assurance: Designed with robust safety factors and features to handle the most demanding loads with confidence, mitigating risks associated with heavy material handling.

Product Applications:

Our Heavy-Duty Steel Swivel Frame Gin Pole is the premier choice for the most challenging and critical lifting and positioning applications in modern power infrastructure:

-

Ultra-Heavy conductor stringing: The definitive tool for lifting and guiding the heaviest multi-bundle UHV/EHV conductors, especially over extreme spans, large river crossings, or in mountainous terrain.

-

Gigantic Transformer & Reactor Installation: Essential for lifting and precisely setting the largest power transformers, shunt reactors, and other immense, high-value equipment within major substations.

-

Colossal Insulator String & Hardware Placement: Provides the necessary capacity and dynamic control for accurately positioning the largest and heaviest insulator assemblies and complex line hardware on ultra-high transmission towers.

-

Major Transmission Tower & Gantry Erection: Used as the primary lifting aid for the assembly and uprighting of large, pre-fabricated sections of the largest transmission towers and substation gantries.

-

Heavy Industrial Lifting: Adaptable for other heavy industrial construction, such as lifting large pipes, pressure vessels, or modular sections in power plants or heavy manufacturing facilities.

-

Substation Busbar & Equipment Installation: For safely lifting and positioning the heaviest busbars, large breakers, disconnect switches, and other substantial electrical equipment within major substations.

-

Emergency Response & Restoration: Crucial for rapid deployment to lift and clear massive debris or replace severely damaged infrastructure components after catastrophic events.

Technical Data Sheet:

Note: The safe working load limit (WLL) of a steel swivel frame gin pole is highly dependent on its height, base configuration, guying setup, angle of pull, and the specific model's design. It is absolutely critical to adhere strictly to the manufacturer's detailed load charts, operating instructions, and all applicable engineering best practices. Comprehensive rigging plans, precise load calculations, and strict adherence to all local safety regulations and advanced training are mandatory for the safe and effective use of this specialized heavy lifting equipment. Professional engineering consultation is typically required for planning and executing complex lifting scenarios involving these poles due to the extreme loads handled. Please contact us for detailed datasheets for specific models, load capacities, and custom engineered lifting system configurations.

Why Choose Ningbo Changshi Electric Power Machinery Manufacturing Limited?

Choosing Ningbo Changshi means partnering with a trusted industry leader dedicated to providing cutting-edge, safe, and immensely robust solutions for your most monumental power line and electrical construction projects. Here’s why our Heavy-Duty Steel Swivel Frame Gin Pole is your ultimate choice:

-

Unrivaled Strength for Extreme Loads: Crafted from high-grade structural steel with a reinforced frame, our gin pole delivers the absolute maximum lifting capacity, confidently handling the heaviest components in the most demanding power infrastructure.

-

Dynamic Multi-Directional Precision: The integrated swivel head provides unparalleled flexibility and control, allowing for exact angular positioning and fluid load orientation, which is crucial for complex, high-value installations.

-

Comprehensive One-Stop Supply Chain Mastery: As a preeminent manufacturer and exporter, we offer an unparalleled array of cutting-edge equipment for both overhead and underground power line projects, streamlining your entire procurement process with a single, reliable source for all your specialized heavy lifting and operational needs.

-

Absolute Safety & Accelerated Project Timelines: Our commitment to superior design and engineering ensures maximum stability and control, significantly mitigating risks associated with heavy material handling and dramatically accelerating the completion of complex projects.

-

Global Trust & Proven Excellence: Our unwavering dedication to quality, innovation, and safety has earned us the trust of leading power utilities and electrical contractors worldwide, making us the undisputed choice for reliable, dynamically controlled, and ultra-high-capacity overhead lifting solutions.

Final Summary:

Our Heavy-Duty Steel Swivel Frame Gin Pole is an indispensable, meticulously engineered heavy lifting tool designed to provide safe, unparalleled strength, and dynamically controlled support for the most demanding loads in overhead transmission line and substation construction. Its robust steel frame construction, combined with its innovative swivel head, makes it the ultimate choice for enhancing efficiency, precision, and safety during critical conductor stringing, equipment installation, and structural erection tasks requiring multi-directional control and extreme lifting capacity. Trust Ningbo Changshi Electric Power Machinery Manufacturing Limited to equip your teams with high-quality, dependable, and intelligently designed specialized heavy lifting solutions.

Conquer your most monumental lifts with supreme strength and dynamic precision! Explore our Heavy-Duty Steel Swivel Frame Gin Poles. Visit