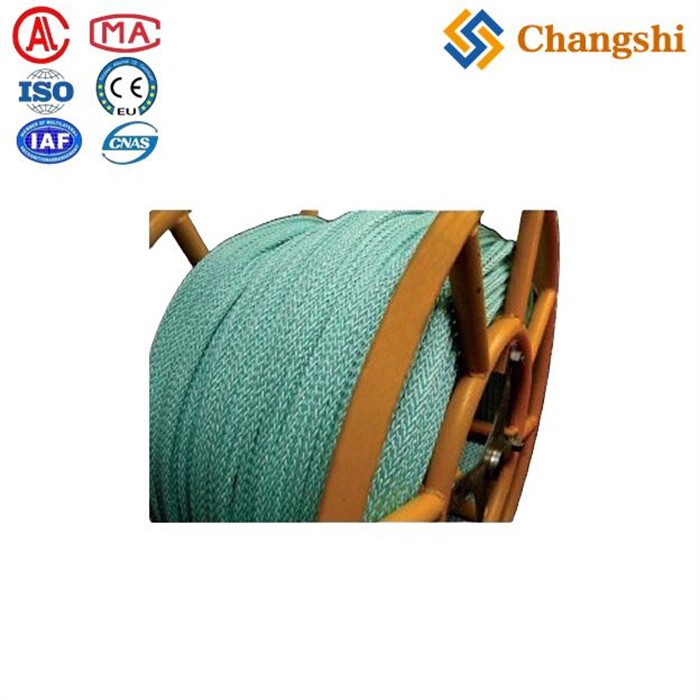

Anti-Twisting Braided Synthetic Fiber Ropes Overhead Transmission Line Stringing

Anti-twisting braided synthetic fiber ropes are high-performance ropes designed to resist twisting and kinking during use, making them ideal for demanding applications such as overhead transmission line stringing, mooring, towing, and industrial lifting.

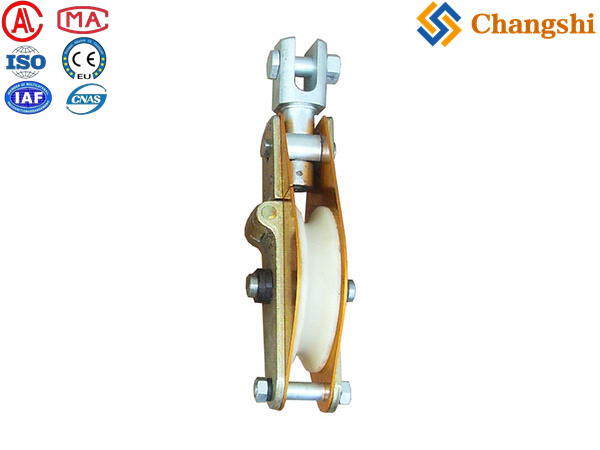

- Transmission Line Wire Cable Conductor Tension Stringing Equipment

- Transmission Conductor Tension Stringing Equipment For Overhead Power Lines

- Tools For Power Lines,Substation,Electrical Construction & Maintenance

- Electric Power Transmission Distribution Line Construction Machine Tools

- Overhead Power Transmission Distribution Line Repair Hardware Fittings

- Underground Cable Laying Pulling Installation Equipment Machine Tools Accessories

- Information

- Video

Anti-twisting braided synthetic fiber ropes are high-performance ropes designed to resist twisting and kinking during use, making them ideal for demanding applications such as overhead transmission line stringing, mooring, towing, and industrial lifting.

-

: These ropes are typically braided with a core designed to prevent the strands from twisting, ensuring stability and maintaining rope integrity under load and in harsh environments.

-

: Commonly made from advanced synthetic fibers such as Ultra-High Molecular Weight Polyethylene (UHMWPE), high-modulus polyethylene (HMPE), or polypropylene. UHMWPE ropes like the Optima 5 offer extremely high strength-to-weight ratios, low elongation, and excellent abrasion and fatigue resistance.

-

: The ropes incorporate design elements such as multi-color patterns for twist identification and special braid constructions to minimize torque and twisting during operation.

-

: These ropes provide very high breaking forces, often comparable to or exceeding steel wire ropes of the same diameter, while weighing significantly less (up to 7 times lighter).

-

: They exhibit excellent resistance to UV light, seawater, oil, dirt, abrasion, and fatigue, ensuring long service life even in challenging conditions.

-

: Synthetic anti-twist ropes are easier and safer to handle than steel wire ropes, with no risk of wire splinters or corrosion-related issues.

-

: Widely used in overhead power line construction for OHTLstringingequipment.com/Conductor-Stringing-Equipment.html target='_blank'>conductor stringing, marine mooring and towing, industrial lifting, and other heavy-duty applications requiring reliable, twist-free rope performance.

-

| Feature | Anti-Twisting Braided Synthetic Fiber Ropes | Steel Wire Ropes |

|---|---|---|

| Weight | Much lighter (up to 7x lighter) | Heavier |

| Strength | Comparable or higher for same diameter | High |

| Twist Resistance | Designed to prevent twisting and kinking | Prone to twisting |

| Corrosion Resistance | Excellent (UV, seawater, oil resistant) | Susceptible to corrosion |

| Handling Safety | No wire splinters, easier to handle | Risk of wire splinters |

| Elongation | Low elongation (e.g., UHMWPE ~3-6%) | Low to moderate |

| Fatigue Resistance | High bending and relaxation fatigue resistance | Moderate |

Anti-twisting braided synthetic fiber ropes combine advanced fiber technology with specialized braid construction to provide lightweight, high-strength, and twist-resistant ropes. Their superior durability, safety, and handling characteristics make them the preferred choice for overhead transmission line stringing, marine, and industrial applications where rope twist and reliability are critical concerns