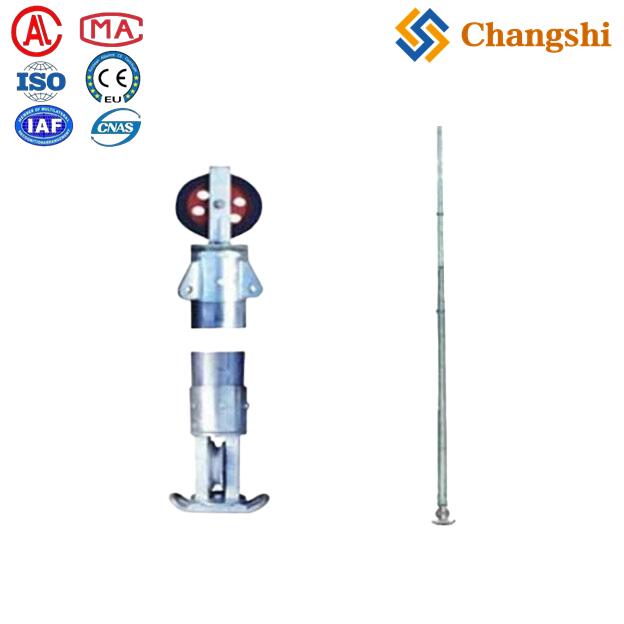

Aluminum A-Frame Gin Pole with Integrated Manual Winch for Controlled Lifting

Achieve precise, controlled lifting with Ningbo Changshi's aluminum alloy A-frame tubular gin pole featuring an integrated manual winch. Ideal for efficient and stable overhead line construction.

- Transmission Line Wire Cable Conductor Tension Stringing Equipment

- Transmission Conductor Tension Stringing Equipment For Overhead Power Lines

- Tools For Power Lines,Substation,Electrical Construction & Maintenance

- Electric Power Transmission Distribution Line Construction Machine Tools

- Overhead Power Transmission Distribution Line Repair Hardware Fittings

- Underground Cable Laying Pulling Installation Equipment Machine Tools Accessories

- Information

- Video

Aluminum Alloy Tubular A-Frame Gin Pole with Manual Winch: Self-Contained Precision Lifting for Overhead Power Line Projects

At Ningbo Changshi Electric Power Machinery Manufacturing Limited, we understand that efficient, safe, and independently controlled lifting capabilities are critical for success in diverse overhead transmission line (OHTL) and distribution construction and maintenance tasks. Our Aluminum Alloy Tubular A-Frame Gin Pole with Manual Winch is a highly versatile and self-contained lifting solution, meticulously engineered to combine the exceptional inherent stability of our A-frame design with the added convenience and precise control of an integrated manual winch. As a prominent China manufacturer and exporter specializing in comprehensive one-stop supply for both overhead transmission line (OHTL) wire cable conductor tension stringing equipment and underground cable laying equipment, this advanced gin pole system exemplifies our unwavering commitment to providing innovative, durable, and highly effective equipment that ensures superior productivity, safety, and operational precision on your job sites, even in challenging environments.

The Aluminum Alloy Tubular A-Frame Gin Pole is renowned for its two-legged, self-supporting structure, which offers significantly enhanced stability compared to single-mast gin poles, particularly advantageous when guying options are limited or precise load positioning is crucial. What sets this specific model apart is the integrated manual winch, which provides a self-contained lifting mechanism, eliminating the need for external pulling machines or complex rigging setups for many tasks. Constructed from high-strength aluminum alloy tubing, the entire unit remains lightweight for its impressive lifting capacity, making it exceptionally portable and easy to transport, assemble, and position on site. The manual winch allows for incremental, controlled raising and lowering of loads, which is vital for delicate operations such as guiding conductors, installing insulator strings, or precisely setting equipment. This system is ideal for tasks requiring careful maneuvering, offering linemen and ground crews a reliable, stable, and independently operable lifting solution that enhances safety, efficiency, and autonomy during critical overhead work.

Product Features & Benefits:

-

Integrated Manual Winch: Features a robust, high-ratio manual winch directly attached to the gin pole, providing a self-contained and controlled lifting and lowering mechanism without the need for external power sources or machinery.

-

Exceptional Freestanding Stability (A-Frame Design): The bipod or A-shape configuration offers superior inherent stability, minimizing reliance on extensive guying and enhancing safety, particularly in varied terrain or congested areas.

-

High Load Capacity & Structural Integrity: Constructed from high-strength aluminum alloy tubing, providing robust lifting capacity for heavy conductors, large insulators, and substantial equipment, crucial for power infrastructure projects.

-

Precise & Controlled Lifting: The manual winch allows for fine control over the lifting and lowering speed, enabling delicate and accurate positioning of loads, minimizing swings and preventing damage.

-

Lightweight & Portable: Despite its integrated winch, the aluminum alloy tubular construction ensures a manageable weight for easier transport, assembly, and repositioning on diverse job sites.

-

Modular & Versatile Heights: Often designed in sectional configurations, allowing for adjustable heights to suit various lifting requirements, structure types, and specific project phases.

-

Durable & Corrosion-Resistant: Aluminum alloy construction provides excellent resistance to corrosion, rust, and environmental wear, ensuring long service life in demanding outdoor conditions.

-

Flexible Setup Options: Can be utilized in various orientations and positions, offering greater adaptability for complex rigging scenarios.

-

Enhanced Safety & Operational Efficiency: The stable design and controlled lifting capabilities significantly mitigate risks associated with uncontrolled loads and ensure a safer, more efficient working environment for ground crews and linemen.

-

Non-Sparking Properties: Aluminum alloy construction inherently reduces the risk of sparking, making it a safer option in various construction environments.

Product Applications:

Our Aluminum Alloy Tubular A-Frame Gin Pole with Manual Winch is an indispensable piece of equipment for a wide array of demanding overhead power line and substation construction and maintenance applications, especially where independent and controlled lifting is paramount:

-

Overhead conductor stringing & Sagging: Ideal for controlled lifting of conductors into Stringing Blocks, or for precisely adjusting conductor sag over spans, especially on distribution lines or in more confined areas.

-

Insulator String & Hardware Installation: Provides stable and controlled lifting for accurately positioning and installing large and heavy insulator assemblies and associated hardware on poles and towers.

-

Distribution Transformer & Equipment Placement: Perfectly suited for lifting and setting distribution transformers, overhead switches, reclosers, and other electrical equipment onto poles or platforms.

-

Pole Setting (Smaller Poles) & Tower Assembly: Can be used for uprighting smaller utility poles or for lifting and positioning sections during the assembly of transmission towers.

-

Line Maintenance & Repair: Essential for replacing damaged components, lifting tools, or materials during routine maintenance or emergency repair operations.

-

underground Cable Pulling (Vertical Access): Can be adapted for vertical pulling of cables from vaults or manholes using the integrated winch, providing a stable overhead pulling point.

-

Substation Auxiliary Lifting: For various lighter to medium-duty lifting tasks within substations where precise, localized control is beneficial.

-

Remote or Difficult Access Sites: Its portability and self-contained nature make it ideal for sites where heavy machinery access is challenging.

Technical Data Sheet:

Note: The safe working load limit (WLL) of an A-frame gin pole with winch is highly dependent on its height, leg spread, proper base setup/anchoring, the winch's capacity, and the specific model's design. It is absolutely critical to adhere strictly to the manufacturer's detailed load charts and operating instructions. Proper rigging practices, load calculations, and strict adherence to all local safety regulations and comprehensive training are paramount for the safe and effective use of this specialized heavy lifting equipment. Please contact us for detailed datasheets for specific models, load capacities, and custom system configurations.

Why Choose Ningbo Changshi Electric Power Machinery Manufacturing Limited?

Choosing Ningbo Changshi means partnering with a trusted industry leader dedicated to providing efficient, safe, and robust solutions for your power line and electrical construction projects. Here’s why our Aluminum Alloy Tubular A-Frame Gin Pole with Manual Winch is your ideal choice:

-

Self-Contained & Precise Lifting: The integrated manual winch provides independent and highly controlled lifting and lowering, offering superior precision for delicate tasks without external power.

-

Unrivaled Stability & Safety: The inherent A-frame design ensures exceptional freestanding stability, significantly reducing reliance on extensive guying and enhancing safety in diverse work environments.

-

Comprehensive One-Stop Supply Chain Mastery: As a preeminent manufacturer and exporter, we offer an unparalleled array of cutting-edge equipment for both overhead and underground power line projects, streamlining your entire procurement process with a single, reliable source for all your specialized lifting and operational needs.

-

Durable, Portable & Efficient: Crafted from high-strength aluminum alloy, it combines robust lifting power with a manageable weight, facilitating easier transport, rapid assembly, and long-term durability in challenging field conditions.

-

Global Trust & Proven Performance: Our unwavering commitment to quality, innovation, and safety has earned us the trust of leading power utilities and electrical contractors worldwide, making us the preferred choice for reliable, stable, and controlled overhead lifting solutions.

Final Summary:

Our Aluminum Alloy Tubular A-Frame Gin Pole with Manual Winch is an indispensable, meticulously engineered self-contained lifting tool designed to provide safe, highly stable, and precisely controlled support for a wide range of loads in overhead transmission line and distribution construction. Its robust yet portable aluminum alloy construction, combined with its inherently stable A-frame design and integrated manual winch, makes it an ideal choice for enhancing efficiency, precision, and safety during critical conductor stringing, equipment installation, and maintenance tasks where independent and controlled lifting is paramount. Trust Ningbo Changshi Electric Power Machinery Manufacturing Limited to equip your teams with high-quality, dependable, and intelligently designed specialized lifting solutions.

Gain precise, controlled lifting power on your next project! Explore our Aluminum Alloy Tubular A-Frame Gin Poles with Manual Winch. Visit