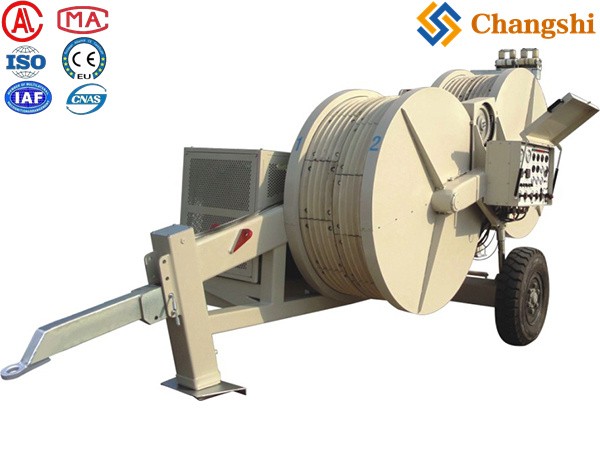

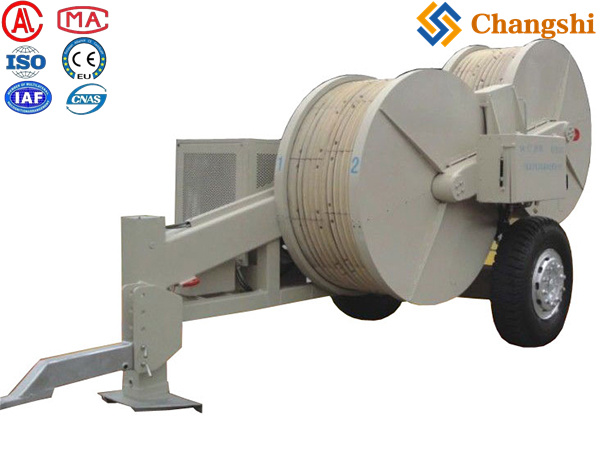

8 Ton Hydraulic Conductor Tensioner | UHV/EHV Bundle Conductor Stringing

Master the most challenging UHV/EHV OHTL projects with Ningbo Changshi's 8-ton hydraulic conductor tensioner. Unrivaled precision, power, & control for heavy & multi-bundle conductor stringing.

- Transmission Line Wire Cable Conductor Tension Stringing Equipment

- Transmission Conductor Tension Stringing Equipment For Overhead Power Lines

- Tools For Power Lines,Substation,Electrical Construction & Maintenance

- Electric Power Transmission Distribution Line Construction Machine Tools

- Overhead Power Transmission Distribution Line Repair Hardware Fittings

- Underground Cable Laying Pulling Installation Equipment Machine Tools Accessories

- Information

- Video

8 Ton Hydraulic Conductor OHTLstringingequipment.com/Hydraulic-Conductor-Tensioners.html target='_blank'>Tensioner: The Ultimate Solution for UHV & Complex Multi-Bundle OHTLstringingequipment.com/Conductor-Stringing-Equipment.html target='_blank'>conductor stringing

On behalf of Ningbo Changshi Electric Power Machinery Manufacturing Limited, a prominent China manufacturer and global exporter specializing in comprehensive tools and equipment for power lines, substations, electrical construction, and maintenance, we are immensely proud to introduce our groundbreaking 8 Ton Hydraulic Conductor Tensioner. This unparalleled, exceptionally powerful, and technologically superior machine is the definitive solution, meticulously engineered to provide absolute precise and robust back tension during the stringing of the heaviest conductors, large OPGW (Optical Ground Wire), and the most intricate multi-bundle conductors (e.g., quadruple and hexagonal bundles) on Ultra-High Voltage (UHV) and Extra-High Voltage (EHV) overhead transmission lines (OHTL). It is truly indispensable for preventing conductors from touching the ground, absolutely safeguarding critical existing infrastructure, and impeccably preserving the conductor's integrity from any nicks, abrasions, or damage, thereby ensuring the long-term reliability, maximum capacity, and supreme operational safety of the world's most vital grid infrastructure.

Our 8-ton hydraulic tensioner offers an unmatched level of control and immense, unyielding power for the most extreme heavy-duty applications. It empowers operators to maintain exact tension values with absolute, unwavering precision, which is non-negotiable for safe and highly efficient stringing operations across the most formidable terrains, record-setting long spans, and with the largest, most complex conductor configurations imaginable. Its supremely robust construction, revolutionary hydraulic system, and intelligent, intuitive controls deliver exceptionally smooth, consistent, and impeccably reliable performance, making it the ultimate, indispensable asset for the most critical, largest-scale, and high-stakes power infrastructure projects globally.

Product Features & Benefits:

The Ningbo Changshi 8 Ton Hydraulic Conductor Tensioner is meticulously engineered for the highest level of control, unparalleled conductor protection, and consistent, uncompromised performance in the most demanding UHV/EHV OHTL stringing operations.

-

Unrivaled 8-Ton (80 kN) Tension Capacity: Provides an unmatched level of precisely controlled back tension, making it the definitive solution for stringing the heaviest single conductors, large-diameter OPGW, and especially complex multi-bundle conductors (e.g., 4-bundle, 6-bundle configurations). This guarantees optimal ground clearance, controlled sag, and meticulous handling of the most valuable and critical high-voltage assets.

-

Revolutionary Dual Closed Hydraulic System: Features a state-of-the-art, dual closed hydraulic circuit (often with independent circuits for each bullwheel set in multi-groove models) that enables infinitely variable tension adjustment and ultra-precise, synchronized speed control across the entire operational range. This advanced, redundant system ensures exceptionally smooth, uniform, and consistent tension application, completely eliminating damaging surges, preventing over-tensioning, and critically protecting the conductor's surface integrity, even under extreme loads.

-

Integrated Digital Control & Data Logging Suite: Equipped with a highly accurate digital tension gauge (dynamometer), digital speedometer, and advanced integrated data logger, providing continuous, real-time display and comprehensive recording of applied tension, stringing speed, distance, and critical operational parameters. This comprehensive feedback empowers operators to precisely monitor and maintain exact tension values, strictly adhering to the most stringent project specifications for quality assurance, paramount safety, and indisputable regulatory compliance.

-

Massive Multi-Groove Bullwheels with Advanced Composite Liners: Features exceptionally large-diameter bullwheels with highly durable, premium-grade, ultra-wear-resistant, multi-groove liners (e.g., advanced polyurethane composites or specialized anti-abrasion materials). This design ensures superior, consistent grip on the pulling rope or conductor, minimizes wear, and rigorously protects the conductor's surface integrity, even with immense loads and continuous, high-intensity operation.

-

Redundant Fail-Safe Braking System: Incorporates a robust, multi-stage automatic negative hydraulic brake system that engages instantly and securely when the machine operation ceases or in the event of any hydraulic pressure loss. This provides a critical, highly reliable, and redundant fail-safe mechanism, immediately holding the conductor in place and significantly enhancing operational safety for personnel and high-value equipment.

-

Independent, Heavy-Duty, Continuous-Duty Power Source: Powered by a high-performance, industrial-grade diesel engine (e.g., renowned global brands like Volvo Penta, Cummins, Deutz, or equivalent, designed for severe duty), engineered for continuous operation under maximum load. This offers complete independence from external power grids and ensures powerful, consistent, and long-duration performance even in the most remote and demanding construction sites globally.

-

Ultimate Heavy-Duty & Unyielding Stable Construction: Built with an extraordinarily reinforced, high-tensile steel chassis and the absolute top-tier, heavy-duty components throughout. This guarantees maximum long-term durability, exceptional resistance to continuous strenuous use, and unwavering stability in the harshest outdoor conditions and the extreme rigors of UHV/EHV OHTL stringing, ensuring unparalleled extended service life and minimal downtime.

-

Ergonomic & Comprehensive Operator Interface: Features an intuitive, ergonomic, and fully-equipped control cabin/panel with clear, rugged displays and robust controls, allowing for precise management of tension, speed, and emergency stops. Advanced models include telematics and remote monitoring capabilities, enhancing operator efficiency, safety, and operational intelligence in the most critical stringing scenarios.

Product Applications:

Our 8 Ton Hydraulic Conductor Tensioner is ideally suited for:

-

Ultra-High Voltage (UHV) & Extra-High Voltage (EHV) Transmission line stringing: The definitive solution for efficient, controlled, and damage-free stringing of the largest single conductors and the most complex multi-bundle conductors (e.g., triple, quadruple, or hexagonal bundles) for UHV and EHV lines worldwide.

-

Mega-Project River & Canyon Crossings: Critical for managing tension over exceptionally long and critical spans where precise conductor control, monumental back tension, and uncompromising safety are paramount.

-

Large-Scale OPGW (Optical Ground Wire) Installation: Essential for the controlled and protective installation of the heaviest OPGW cables, safeguarding the integrated fiber optics across vast distances.

-

Global Grid Modernization & Expansion Initiatives: Indispensable for the controlled removal of old, heavy conductors and the safe, efficient installation of new, high-capacity, or complex bundled conductors on vital existing transmission infrastructure.

-

Extremely Complex Terrain & Remote Operations: Providing the necessary immense power, ultimate control, and rugged dependability for stringing operations in the most inaccessible mountainous, forested, desert, or challenging terrains globally.

-

International Interconnection & Super Grid Projects: A crucial, high-performance asset for projects connecting national and continental grids, where reliability, extreme precision, and unparalleled capacity are non-negotiable.

Why Choose Ningbo Changshi Electric Power Machinery Manufacturing Limited or Partner With Us?

At Ningbo Changshi, we offer comprehensive one-stop supply and services for both overhead transmission line wire cable conductor tension stringing equipment and underground cable laying equipment. Our unwavering commitment to global excellence is reflected in:

-

Leading-Edge UHV/EHV Manufacturing Authority: As a prominent China manufacturer, we are at the absolute forefront of designing and producing the highest-capacity power line stringing equipment for the global market. Our 8 Ton Hydraulic Conductor Tensioner embodies our deep expertise and unwavering focus on ultimate precision, paramount safety, and absolute conductor integrity, directly addressing the most critical and demanding requirements of the global energy grid.

-

Trusted Global Exporter & Unrivaled Worldwide Support: We have meticulously built a formidable reputation as a trusted global exporter, consistently providing robust equipment and comprehensive, proactive after-sales support worldwide. Our dedicated international team ensures seamless logistics, punctual delivery, and highly responsive technical assistance for your projects across all continents, guaranteeing uninterrupted project flow and maximum uptime.

-

Comprehensive Integrated Solutions: From specialized, ultra-high-capacity tensioning equipment like this 8-ton unit to robust pullers, advanced underground cable tools, and an extensive array of overhead accessories, our wide product range empowers you to consolidate your procurement with a single, highly reliable partner, significantly simplifying logistics, reducing procurement complexity, and maximizing overall project efficiency.

-

Innovation Driving Peak Performance & Uncompromised Safety: We continuously invest substantially in cutting-edge research and development, integrating the latest advancements in hydraulics, control systems, and material science to bring innovative solutions that significantly enhance performance, amplify safety, and boost overall efficiency on your critical job sites. Our advanced hydraulic tensioning technology is a prime example of this commitment.

-

Strategic Client Partnership: We firmly believe in forging strong, enduring strategic partnerships. Our highly experienced experts work intimately with you to deeply understand your unique, complex project challenges, meticulously offering bespoke equipment solutions and proactive, hands-on support for mutual, resounding success. We are not just a supplier; we are your dedicated, long-term partner in achieving your most ambitious infrastructure goals.

Technical Data Sheet: 8 Ton Hydraulic Conductor Tensioner

Note: Specifications are approximate and may vary significantly based on specific model configurations, customization for particular bundle conductor arrangements, and continuous product improvements. For the most current and precise technical data, or to discuss bespoke solutions for your most demanding, large-scale, and complex high-voltage projects, please contact our specialized sales and engineering team directly.

Final Summary:

At Ningbo Changshi Electric Power Machinery Manufacturing Limited, we are the definitive global leader in providing unparalleled, cutting-edge solutions that ensure the utmost safety, efficiency, and long-term integrity of the world's most critical power infrastructure projects. Our 8 Ton Hydraulic Conductor Tensioner stands as the ultimate testament to this unwavering commitment, offering commanding power, absolute precision, and uncompromised reliability for the most demanding UHV/EHV, multi-conductor, and ultra-long span overhead transmission line stringing operations.

Revolutionize your most ambitious transmission line projects with the unmatched power, precision, and reliability of Ningbo Changshi's 8 Ton Hydraulic Conductor Tensioner. Contact our elite team today to engage our experts, request a comprehensive, project-specific quote, or explore our full suite of world-class overhead transmission line equipment. Let Ningbo Changshi be your strategic, indispensable partner for unparalleled performance and resounding success on every critical, high-stakes global project!