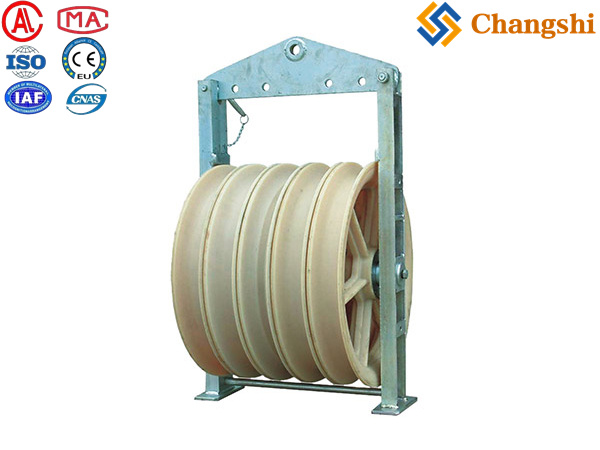

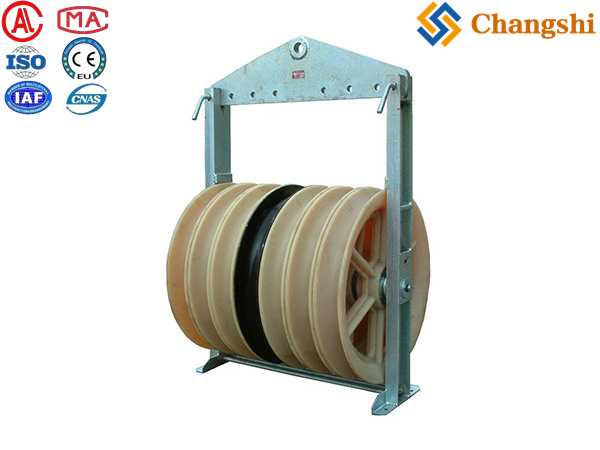

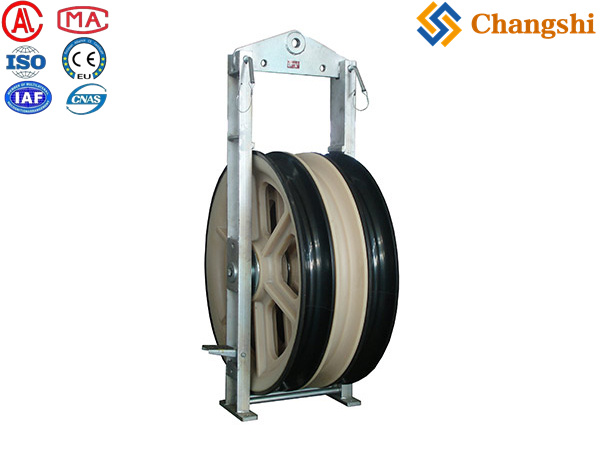

1160mm Apex Stringing Block | Ultra-Large Conductor Protection Pulley

Achieve zero-stress stringing with Ningbo Changshi's 1160mm Apex Stringing Block. Engineered for the largest, most sensitive multi-bundle conductors in UHV/HVDC, ensuring pristine line integrity & peak efficiency for global mega-projects.

- Transmission Line Wire Cable Conductor Tension Stringing Equipment

- Transmission Conductor Tension Stringing Equipment For Overhead Power Lines

- Tools For Power Lines,Substation,Electrical Construction & Maintenance

- Electric Power Transmission Distribution Line Construction Machine Tools

- Overhead Power Transmission Distribution Line Repair Hardware Fittings

- Underground Cable Laying Pulling Installation Equipment Machine Tools Accessories

- Information

- Video

1160mm Apex Stringing Block: Redefining Conductor Protection for the World's Most Ambitious Transmission Projects

On behalf of Ningbo Changshi Electric Power Machinery Manufacturing Limited, a prominent China manufacturer and global exporter specializing in comprehensive tools and equipment for power lines, substations, electrical construction, and maintenance, we are immensely proud to unveil our groundbreaking 1160mm Apex Stringing Block. This monumental piece of engineering stands as the definitive solution for the most demanding and critical overhead transmission line (OHTL) projects globally, specifically designed to flawlessly handle the largest, heaviest, and most complex multi-bundle conductor configurations for next-generation Ultra-High Voltage (UHV) and High Voltage Direct Current (HVDC) systems.

The extraordinary 1160mm (approximately 45.7 inches) diameter of this stringing block represents the largest possible bending radius for conductors, setting an unparalleled industry standard for conductor preservation. This colossal size is paramount for maintaining the absolute pristine mechanical and electrical integrity of extremely valuable multi-conductor bundles (e.g., 8, 10, 12, or even more conductors per bundle), completely eliminating the risk of internal stress, outer strand deformation, or surface damage that even large, but comparatively smaller, blocks might cause. Featuring robust, aerospace-grade materials, an unmatched load capacity, and ultra-precision bearing systems, Ningbo Changshi's 1160mm Apex Stringing Block ensures exceptionally low friction, unwavering stability, and flawlessly smooth passage of conductors. This guarantees optimal performance, maximum conductor lifespan, and ultimate reliability for the world's most critical power infrastructure developments, pushing the boundaries of what's possible in transmission engineering.

Product Features & Benefits:

The Ningbo Changshi 1160mm Apex Stringing Block embodies the zenith of engineering, designed for absolute conductor protection, supreme performance, and operational excellence in the most extreme stringing applications.

-

Unparalleled Conductor Preservation (1160mm Diameter): This record-setting sheave diameter provides the largest possible bending radius for conductors, which is absolutely vital for safeguarding the largest single conductors and the most complex, highest-count multi-bundle configurations from any form of damage or deformation during the entire stringing process.

-

Zero-Defect Conductor Handling & Integrity: Meticulously designed, often with specialized and replaceable wear-resistant linings (e.g., advanced high-density polyurethane or precision-machined aluminum alloy profiling), the deep, ultra-smooth groove precisely cradles conductors, preventing any abrasion, kinking, or stress, ensuring they remain in pristine, factory-new condition.

-

Extreme Load Capacity & Unyielding Structural Integrity: Fabricated from aerospace-grade, high-strength forged aluminum alloys and/or heavy-duty structural steels, the frame and sheave are engineered to sustain the most immense dynamic and static loads encountered during the stringing of the heaviest and longest UHV/HVDC lines, ensuring unparalleled safety and reliability in record-breaking operations.

-

Pinnacle of Friction Reduction (Hyper-Precision Bearings): Equipped with state-of-the-art, multi-row, hermetically sealed tapered roller bearings with near-zero friction coefficients. This system provides exceptionally smooth, silent conductor movement, minimizes pulling tension requirements, extends the lifespan of both the block and the pulling equipment, and offers an unmatched operational lifespan.

-

Absolute Safety & Redundant Conductor Retention System: Features an advanced, multi-point, interlocked safety latch and robust closure system that provides the ultimate security, completely preventing conductor escape even under the most severe wind loads, vibrations, or unforeseen extreme dynamic events.

-

Superior Corrosion & Environmental Fortification for Decades: All components undergo the most rigorous surface treatments, including industrial-grade anodization for aluminum and heavy-duty hot-dip galvanization for steel, ensuring maximum resistance against corrosion, extreme UV radiation, and the harshest environmental elements across decades of service.

-

Dynamic Load Balancing & Precision Alignment: Incorporates a heavy-duty, multi-axis, fully articulating spherical bearing Swivel attachment eye or robust clevis, allowing the block to precisely self-align with complex pulling forces and sag curves. This evenly distributes loads and dramatically reduces torsional stress on both the conductors and the tower structures, even in dynamic situations.

-

Service-Optimized Modular Design: Despite its monumental size and robustness, the intelligent modular design facilitates straightforward inspection and rapid component replacement (e.g., liner changes), ensuring maximum uptime and an extended operational life for your critical, long-term investment.

Product Applications:

Our 1160mm Apex Stringing Block is the definitive choice for the most colossal, innovative, and critical power transmission infrastructure projects globally:

-

Frontier Ultra-High Voltage (UHV) & High Voltage Direct Current (HVDC) Line Construction: Absolutely essential for installing the largest and most intricate multi-bundle conductors (e.g., 8x, 10x, 12x bundles) on next-generation transmission systems, where optimal efficiency, zero conductor damage, and peak integrity are non-negotiable.

-

Record-Setting Super Long-Span Crossings: Indispensable for extreme river, canyon, or mountain crossings that extend for multiple kilometers, where minimizing conductor sag, maintaining precise tension, and preventing any form of damage over immense distances are critical for project success and long-term reliability.

-

Installation of Hyper-Sensitive & Maximum-Value Conductors: Provides the gentlest possible handling for custom-designed, very large diameter conductors or those with highly sensitive composite cores/coatings, ensuring their flawless installation and uncompromised long-term performance.

-

Extreme High-Tension Stringing Projects: Perfectly integrated with the highest capacity OHTLstringingequipment.com/Hydraulic-Conductor-Tensioners.html target='_blank'>Tensioners and pullers, enabling seamless and controlled operation under the most severe tension levels required by mega-projects that push engineering boundaries.

-

Global Grid Interconnection & Super-Grid Development: Crucial for large-scale, cross-continental transmission lines that demand the absolute highest levels of reliability, efficiency, and conductor protection during construction to ensure stable international power flow.

-

Strategic Re-conductoring of Critical EHV/UHV Lines: Enables the safest and most efficient replacement of conductors on vital existing infrastructure, minimizing system downtime for essential grid upgrades where any disruption is simply unacceptable.

Why Choose Ningbo Changshi Electric Power Machinery Manufacturing Limited or Partner With Us?

At Ningbo Changshi, we offer comprehensive one-stop supply and services for both overhead transmission line wire cable conductor tension stringing equipment and underground cable laying equipment. Our unwavering commitment to global excellence is reflected in:

-

Engineering Vision for Global Infrastructure: As a prominent China manufacturer, we are not just a supplier; we are a visionary engineering partner for the world's most ambitious power infrastructure projects. Our 1160mm Apex Stringing Block epitomizes our foresight and capability in delivering groundbreaking solutions for the future of UHV/HVDC transmission.

-

Trusted Global Exporter & Unparalleled Supply Chain Mastery: We have meticulously built a formidable reputation as a trusted global exporter, consistently providing robust equipment and mission-critical accessories to clients worldwide. Our dedicated international team ensures seamless logistics, punctual delivery, and the most reliable supply of our largest-capacity blocks, guaranteeing uninterrupted progress on your highest-stakes projects, anywhere on the globe.

-

Holistic Solutions for Mega-Projects: Our expansive product portfolio encompasses everything from the most powerful Tensioners and pullers to essential jumbo Stringing Blocks and highly specialized tools. By consolidating your procurement with us, you achieve perfect equipment synergy, radically simplify project management, and unlock unparalleled operational efficiency across your entire project lifecycle, ensuring cohesive and optimal performance.

-

Absolute Commitment to Conductor Longevity & Grid Resilience: We recognize that the pristine integrity of conductors is the bedrock of a robust and resilient transmission grid. Our 1160mm block is designed with an uncompromising, meticulous focus on preserving conductor health during installation, directly translating to significantly extended line lifespan, drastically reduced maintenance, and supreme grid performance for decades to come, safeguarding your multi-billion dollar investments.

-

Strategic Partnership for Unquestionable Success: We firmly believe in forging strong, enduring strategic partnerships. Our highly experienced engineers and project specialists work intimately with you to navigate the complexities and sheer scale of your ultra-high voltage projects, offering not just products, but unparalleled expertise, innovative solutions, and bespoke support to ensure the absolute success, safety, and operational excellence of your monumental power infrastructure developments. Partner with Ningbo Changshi for a definitive, future-proof competitive advantage that sets you apart.

Technical Data Sheet: 1160mm Apex Stringing Block

Note: Specific working load limits, breaking loads, and exact dimensions are highly dependent on the specific model, material choices, and advanced design optimizations for various multi-bundle configurations. For the most current and precise technical data, or to specify a stringing block for your particular UHV/HVDC mega-project requirements, please contact Ningbo Changshi Electric Power Machinery Manufacturing Limited directly.

Final Summary:

At Ningbo Changshi Electric Power Machinery Manufacturing Limited, we provide the ultimate in specialized equipment to ensure the unprecedented success and long-term integrity of your most monumental power infrastructure projects globally. Our 1160mm Apex Stringing Block is a mission-critical investment, meticulously engineered to provide unparalleled conductor protection, dramatically reduce friction, and facilitate impeccably smooth and efficient stringing operations for the largest and most complex transmission lines worldwide.

Secure the future reliability and optimize the construction of your most critical power grid. Choose Ningbo Changshi's 1160mm Apex Stringing Block for the absolute pinnacle of conductor protection and operational excellence on your most ambitious UHV/HVDC mega-projects. Contact our expert team today to discuss your specific requirements, request a comprehensive quote, or place an order. Let Ningbo Changshi be your trusted partner for superior overhead transmission line equipment that sets new global industry benchmarks!