Cable Stringing Equipment

Cable stringing equipment encompasses a variety of specialized tools and machines used in the installation, tensioning, and maintenance of overhead power transmission lines. These tools ensure conductors (wires) are pulled through transmission towers, tensioned properly, and positioned accurately for high-voltage systems.

-

: Hydraulic or mechanical pullers and tensioners that apply controlled pulling force to string conductors over long distances. For example, hydraulic pullers with capacities of up to 6 tons and tensioners up to 4 tons are common for heavy-duty stringing operations.

-

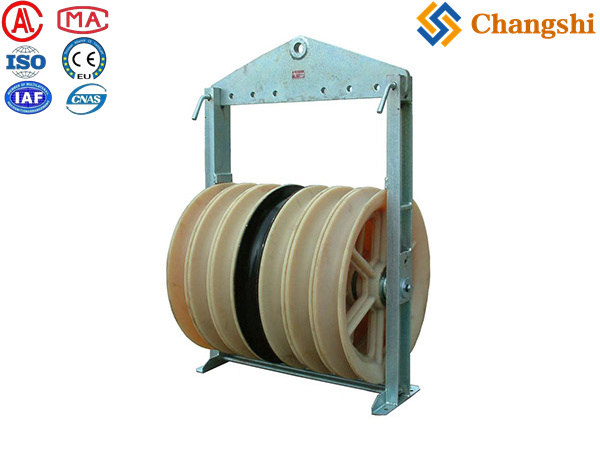

: Pulleys and blocks used to guide and support the conductor wire during stringing, reducing friction and preventing damage.

-

: Devices that securely grip the conductor for pulling without damage.

-

: Equipment to handle and control the reels of conductor cable during stringing, often with hydraulic reel stands and braking systems.

-

: Used to adjust tension and alignment of conductors during installation.

-

: Facilitate smooth laying of conductors along the transmission line path, protecting the conductor from damage.

-

These machines often have closed hydraulic circuits with variable displacement pumps for precise control of pulling force.

-

They include safety features such as automatic overload protection and braking systems.

-

Typical machines are equipped with diesel engines and hydraulic systems for mobility and power.

-

Stringing equipment is used for stringing single conductors, earth wires, OPGW (Optical Ground Wire), and ADSS (All-Dielectric Self-Supporting) optical fiber cables.

-

They are essential in construction and maintenance of low, medium, and high voltage overhead transmission lines.

-

Advanced equipment includes digital dynamometers for tension measurement and swivel joints to prevent conductor twisting.