Electric Engine Powered Cable Pulling Winch For Overhead Power Transmission Line

An electric engine powered cable pulling winch is a specialized device designed for pulling, laying, or lifting cables in construction, utility, and industrial applications. These winches are powered by electric motors, offering reliable, efficient, and environmentally friendly operation compared to fuel-powered alternatives.

- Transmission Line Wire Cable Conductor Tension Stringing Equipment

- Transmission Conductor Tension Stringing Equipment For Overhead Power Lines

- Tools For Power Lines,Substation,Electrical Construction & Maintenance

- Electric Power Transmission Distribution Line Construction Machine Tools

- Overhead Power Transmission Distribution Line Repair Hardware Fittings

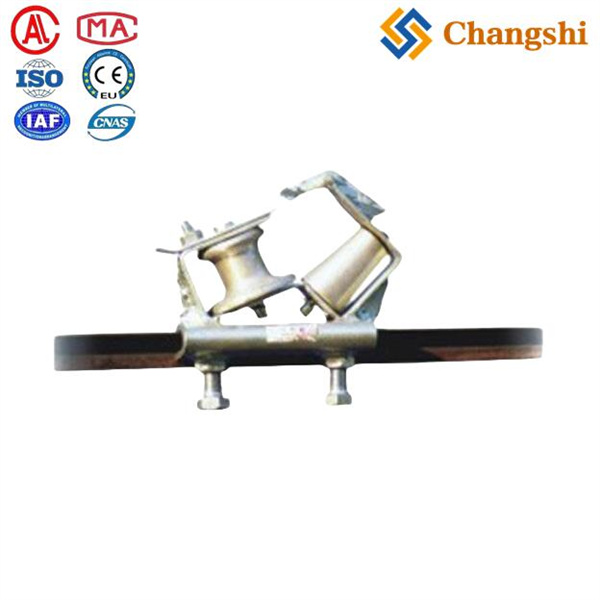

- Underground Cable Laying Pulling Installation Equipment Machine Tools Accessories

- Information

- Video

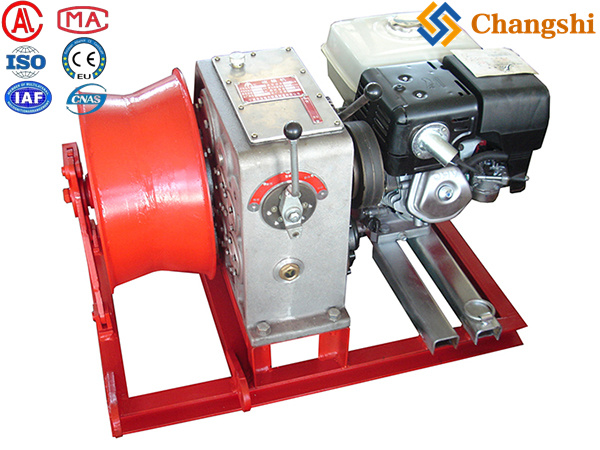

Electric Engine Powered Cable Pulling Winch

An electric engine powered Cable Pulling Winch is a specialized device designed for pulling, laying, or lifting cables in construction, utility, and industrial applications. These winches are powered by electric motors, offering reliable, efficient, and environmentally friendly operation compared to fuel-powered alternatives.

-

: Utilizes single-phase or three-phase electric motors, typically ranging from 1 kW to 9 kW, depending on the model and required pulling force.

-

: Available in a wide range of capacities, from light-duty (200–400 kg) to heavy-duty (up to 3,000 kg or more).

-

: Supports various rope lengths (from 10 m to over 1,000 m) and diameters (typically 3.5 mm to 9 mm), depending on the application.

-

: Many models offer variable or fixed pulling speeds, commonly between 1.4 m/min and 75 m/min.

-

: Overload protection, emergency stop, automatic cable tear protection, and limit switches are standard on many models.

-

: Compact and lightweight designs are available for easy transport and installation, with some models featuring wheels or handles.

-

: Constructed with robust steel frames and corrosion-resistant finishes for long service life.

-

Power and telecommunication cable installation

-

Overhead and underground cable stringing

-

Industrial and construction site cable handling

-

Utility maintenance and repair

-

| Model/Type | Pulling Force | Rope Length | Rope Speed | Motor Power | Weight | Voltage |

|---|---|---|---|---|---|---|

| KE-500 (Jakob Thaler) | 500 daN | 250–400 m | 36 m/min | 1.5 kW | 150 kg | 230/400V, 3-ph |

| KE-1600 (Jakob Thaler) | 1600 daN | 250–400 m | 30 m/min | 1.5 kW | 330 kg | 230/400V, 3-ph |

| TSW 2000 (Jakob Thaler) | 2000 daN | — | 10 m/min | 1.1 kW | 61 kg | 230/400V, 3-ph |

| DED7913 | 200–400 kg | 12.5 m | 4–8 m/min | 1.0 kW | 17.5 kg | 220–240V, 1-ph |

| XPOtool 64346 | 2,267 kg | 10 m | 1.38 m/min | 450 W | — | 220–240V, 1-ph |

| Gebuwin e-Winch | 1,000 kg | — | — | — | — | 380–415V, 3-ph |

-

: No emissions, suitable for indoor and outdoor use.

-

: Fewer moving parts and no fuel system to maintain.

-

: Delivers steady pulling force and speed.

-

: Enhanced with built-in overload and emergency stop features.

-

Always check the winch’s rated capacity before use.

-

Ensure the winch is securely mounted and the cable is properly wound.

-

Do not exceed the specified load capacity.

-

Use appropriate personal protective equipment (PPE) during operation.

-

Regularly inspect the winch and cable for wear or damage.

Electric engine powered cable pulling winches are essential tools for efficient and safe cable installation in a variety of settings. Their versatility, safety features, and ease of use make them a preferred choice for many professionals in the power, telecom, and construction industries