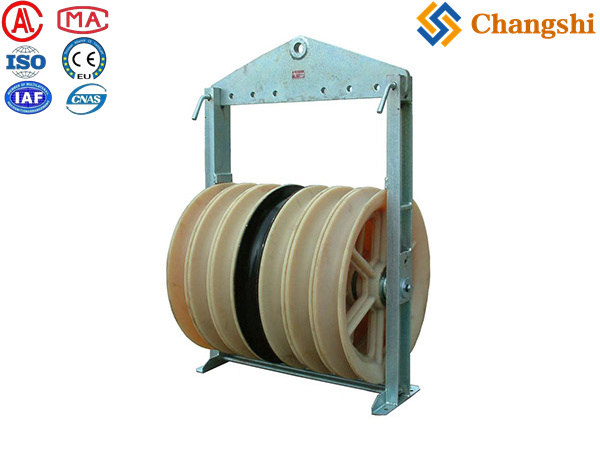

Anti-Twisting Steel Rope Grip Clamp For Overhead Transmission Line Construction And Cable Pulling Operations

An anti-twisting steel rope grip is a specialized clamp designed to securely hold and grip anti-twisting steel wire ropes, commonly used in overhead transmission line construction and cable pulling operations. These grips are engineered to prevent the rope from rotating or twisting under load, ensuring stability and safety during stringing or pulling tasks.

- Transmission Line Wire Cable Conductor Tension Stringing Equipment

- Transmission Conductor Tension Stringing Equipment For Overhead Power Lines

- Tools For Power Lines,Substation,Electrical Construction & Maintenance

- Electric Power Transmission Distribution Line Construction Machine Tools

- Overhead Power Transmission Distribution Line Repair Hardware Fittings

- Underground Cable Laying Pulling Installation Equipment Machine Tools Accessories

- Information

- Video

An anti-twisting steel rope grip is a specialized clamp designed to securely hold and grip anti-twisting steel wire ropes, commonly used in overhead transmission line construction and cable pulling operations. These grips are engineered to prevent the rope from rotating or twisting under load, ensuring stability and safety during stringing or pulling tasks.

-

: The grip typically includes compression nuts or bolts that must be tightened repeatedly to achieve a secure hold on the rope, accommodating the rope’s unique braided structure and preventing slippage.

-

: Specifically made for anti-twisting braided steel wire ropes, which consist of even-numbered braided strands twisted with equal right-hand and left-hand lays to prevent radial rotation.

-

: Made from high-strength steel or alloy materials, often galvanized or treated for corrosion resistance to withstand outdoor and heavy-duty use.

-

: The grip jaws are designed to apply sufficient pressure to the rope strands without damaging them, maintaining the rope’s anti-twist properties while providing a high slipping resistance.

-

: Proper gripping force and jaw geometry ensure that the grip resists slipping even when the rope is subjected to twisting moments. Longer jaw lengths and optimized gripping pressures enhance slipping resistance.

-

: Widely used for securing pilot ropes, pulling ropes, and anti-twisting steel wire ropes in overhead transmission line erection, underground cable laying, and other heavy lifting or pulling operations.

-

-

Anti-twisting steel ropes have a hexagonal or square cross-section braided from 8, 12, or 18 strands, providing high stability against rotation.

-

Grips must balance gripping force to avoid excessive wear ("digging") on the rope strands while maintaining secure holding.

-

Studies show that slipping resistance varies with gripping pressure and jaw length; industrial grips with jaw lengths over 180 mm maintain slipping resistance well even under twisting moments.

-

Typical gripping pressures used in industry are around 9.8 MPa, balancing grip security and rope/jaw wear.

Anti-twisting steel rope grips are essential tools for securely clamping braided anti-twist steel wire ropes during stringing and pulling operations in power line construction. Their design ensures stable, non-rotating rope handling by applying controlled gripping force through optimized jaw geometry and length. This prevents rope slippage and preserves the rope’s anti-twisting characteristics, enhancing operational safety and efficiency.

These grips are compatible with various sizes of anti-twisting braided steel wire ropes, which are typically galvanized for corrosion resistance and come in multiple strand configurations and diameters to suit different project needs