Products

Power transmission and distribution line wire cable conductor tension stringing equipment and machine tools are specialized devices used to safely and efficiently install conductors (wires) on overhead power lines. These tools ensure proper tensioning, pulling, and alignment of cables during stringing operations, which is critical for the reliability and safety of electrical transmission systems.

Core Equipment Types

Hydraulic Pullers and Tensioners: These machines apply controlled tension and pulling force to conductors and earth wires during stringing. Hydraulic tensioners provide constant tension control with adjustable torque to prevent cable damage. For example, a 30 kN hydraulic cable tensioner features a bullwheel with wear-resistant nylon lining, infinitely variable tension control, and automatic spring-applied hydraulic-released brakes for safety.

Puller-Tensioners: Combined units that can both pull and tension conductors simultaneously, often with multiple hydraulic circuits to control several conductors independently. They improve efficiency by allowing simultaneous stringing of multiple phases.

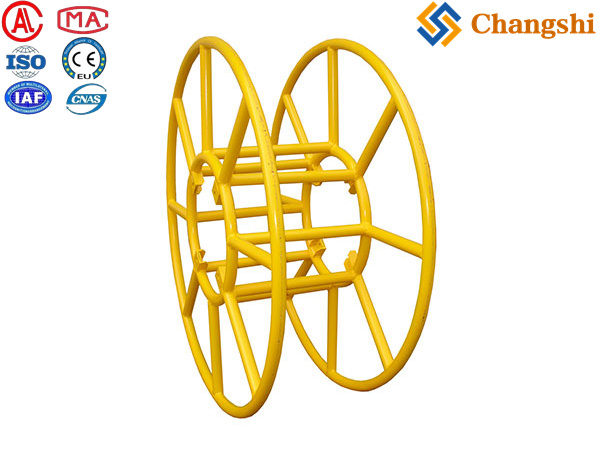

Reel Stands and Drum Stands: Heavy-duty stands hold reels of conductor or cable and allow smooth payout. Some include integrated disc tension brakes and hydraulic drives to control reel rotation and tension during payout.

Stringing Blocks and Sheaves: Pulleys and rollers mounted on poles or structures guide conductors along the route, reducing friction and preventing damage during stringing.

Cable Grips and Pulling Ropes: Attach securely to conductors for pulling without damage, often used with swivel joints to prevent twisting.

Pilot Line Winders and Accessories: Used for initial pulling of pilot lines before main conductor stringing.

Features and Advantages

Adjustable and Constant Tension Control: Hydraulic tensioners maintain constant conductor tension at all stringing speeds and hold tension when stopped, preventing conductor damage and sagging.

Safety Mechanisms: Automatic brakes engage in case of hydraulic failure, and mechanical disc brakes provide reliable tension control.

High Capacity and Versatility: Equipment is rated for loads from a few tons up to several tens of tons, suitable for various conductor sizes and types including ACSR, AAAC, and HTLS conductors.

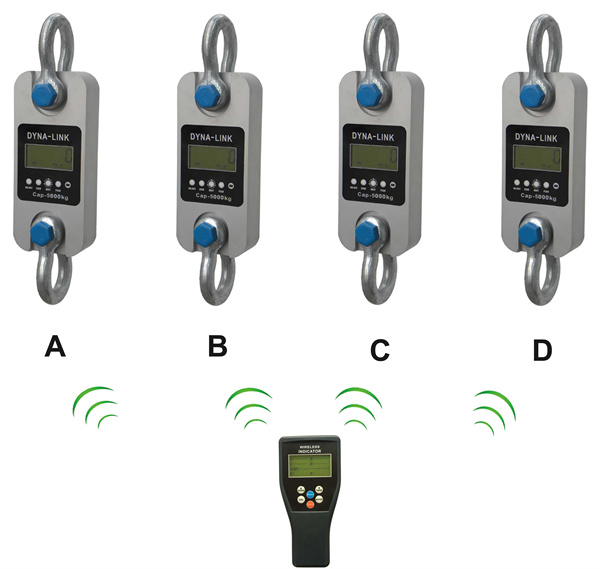

Integrated Electronic Monitoring: Some advanced machines include electronic devices to monitor and record working parameters, enhancing operational control and safety.

Wide Application Range: Suitable for high, extra, and ultra-high voltage overhead lines, medium voltage distribution lines, fiber optic ground wires (OPGW), and underground cables.

Typical Workflow in Stringing Operations

Pilot Line Installation: Using pilot line winders and pulling ropes to establish a path.

Conductor Pulling and Tensioning: Hydraulic pullers and tensioners apply controlled tension to pull conductors from reels held on reel stands.

Guiding Conductors: Stringing blocks and sheaves guide conductors around corners and obstacles.

Tension Monitoring: Tension meters and dynamometers ensure conductor tension remains within safe limits.

Final Securing: Conductors are fastened and tensioned to design specifications using turnbuckles and tensioning tools.

Summary

Power transmission and distribution line conductor tension stringing equipment encompasses hydraulic pullers, tensioners, puller-tensioners, reel stands with braking systems, stringing blocks, cable grips, and related accessories. These tools enable safe, efficient, and precise conductor installation by controlling tension and payout, reducing labor, and preventing conductor damage. They are essential for constructing and maintaining overhead transmission and distribution lines across voltage classes and conductor types.

This overview synthesizes key equipment types and features from multiple industry sources to provide a comprehensive understanding of conductor tension stringing machinery and tools