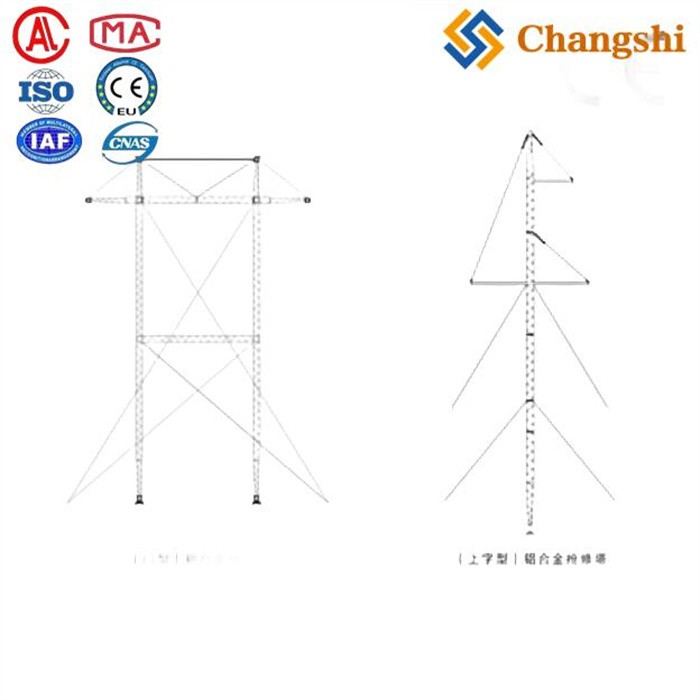

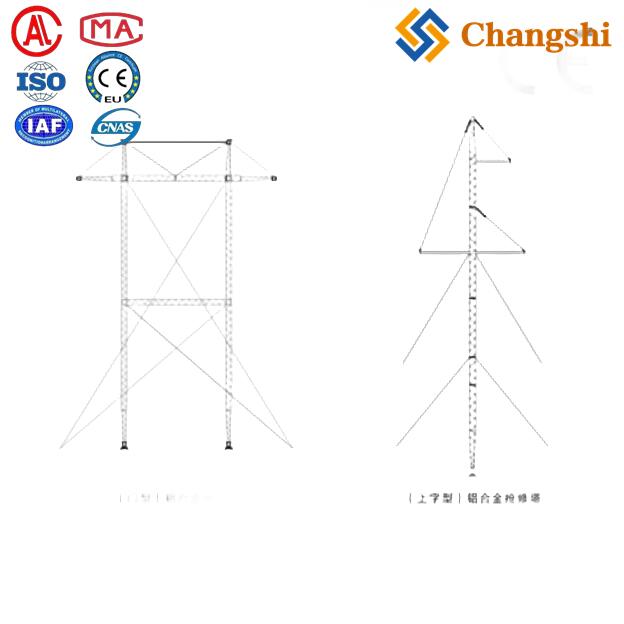

Lattice Aluminum Alloy Emergency Restoration Tower For Power Lines Restoration

The Lattice Type Aluminum Alloy Emergency Restoration Tower is a specialized lightweight, corrosion-resistant tower designed primarily for rapid deployment in emergency power line restoration and related applications.

- Transmission Line Wire Cable Conductor Tension Stringing Equipment

- Transmission Conductor Tension Stringing Equipment For Overhead Power Lines

- Tools For Power Lines,Substation,Electrical Construction & Maintenance

- Electric Power Transmission Distribution Line Construction Machine Tools

- Overhead Power Transmission Distribution Line Repair Hardware Fittings

- Underground Cable Laying Pulling Installation Equipment Machine Tools Accessories

- Information

- Video

The Lattice Type Aluminum Alloy Emergency Restoration Tower is a specialized lightweight, corrosion-resistant tower designed primarily for rapid deployment in emergency power line restoration and related applications.

-

: Made from high-strength aluminum alloy, commonly 6005 or 6082-T6, which offers excellent strength-to-weight ratio, corrosion resistance, and durability. The aluminum alloy is often aged with T6 heat treatment for enhanced mechanical properties.

-

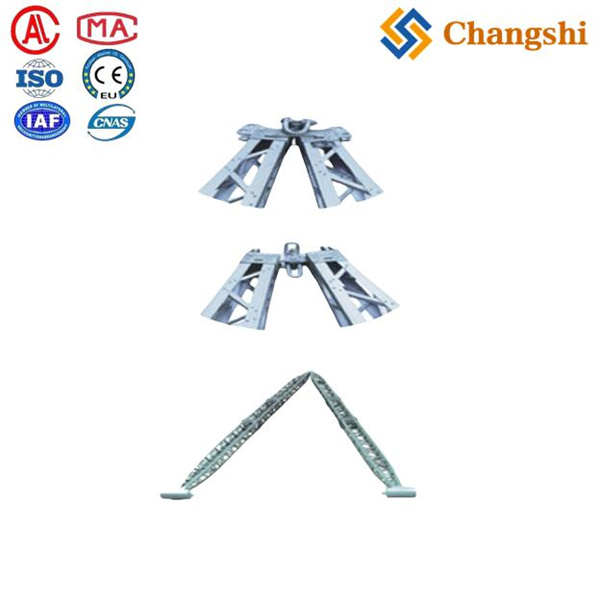

: Typically a lattice framework composed of multiple aluminum alloy columns and circular crossbars forming triangular or portal-framed sections. Sections are modular, usually 3 meters or 6 meters in length, bolted together without welding to facilitate quick assembly and disassembly.

-

:

-

Single-leg or portal-framed structures depending on the model; portal-framed types are common for 110kV and 220kV restoration towers.

-

The lattice design is optimized via CAD/CAE and finite element analysis to ensure strength, stability, and compliance with Eurocodes or other structural standards.

-

The tower is designed to withstand harsh environmental conditions, including wind speeds over 40 m/s and icing loads, making it suitable for high-altitude or severe weather area.

-

Components are CNC machined for precision and assembled with bolts, eliminating welding to reduce weight and improve maintainability.

-

-

:

-

Heights vary widely, with some models reaching up to 45 meters or more.

-

Cross-section widths typically range from 600 mm to 1200 mm depending on the tower type and application.

-

Weight per section is relatively low (e.g., 55-66 kg per 3m section), facilitating transport and rapid erection.

-

-

:

-

Emergency restoration of power lines after outages or damage.

-

Temporary or permanent support for transmission lines, communication antennas, or monitoring equipment.

-

Suitable for use in rugged or remote locations due to its lightweight and corrosion-resistant properties.

-

-

:

-

Painted with electrostatic coatings in aviation safety colors (e.g., red RAL3020 and white RAL9010) for visibility and corrosion protection.

-

Compatible with accessories like crossing structures and lifters for installation support.

-

Certified for structural safety and compliance with relevant standards (Eurocode, AS standards, etc.).

-

-

The Lattice Type Aluminum Alloy Emergency Restoration Tower is a modular, lightweight, and corrosion-resistant tower system designed for quick deployment and reliable structural performance in emergency power restoration and related infrastructure tasks. Its aluminum alloy construction ensures ease of transport and assembly, while its robust lattice design provides stability under severe weather conditions and heavy loads. Various configurations (single-leg or portal-framed) and heights are available to suit different voltage levels and operational requirements。