Cable Corner Bend Turning Guide Roller for Cable Installation Maintenance Repair

A cable turning roller (also known as a cable guide roller, corner roller, or bend roller) is a specialized type of cable roller designed to guide cables smoothly around corners, bends, or edges during installation, maintenance, or repair . Its primary function is to prevent cable damage by reducing friction and tension as the cable changes direction.

- Transmission Line Wire Cable Conductor Tension Stringing Equipment

- Transmission Conductor Tension Stringing Equipment For Overhead Power Lines

- Tools For Power Lines,Substation,Electrical Construction & Maintenance

- Electric Power Transmission Distribution Line Construction Machine Tools

- Overhead Power Transmission Distribution Line Repair Hardware Fittings

- Underground Cable Laying Pulling Installation Equipment Machine Tools Accessories

- Information

- Video

A cable turning roller (also known as a cable guide roller, corner roller, or bend roller) is a specialized type of cable roller designed to guide cables smoothly around corners, bends, or edges during installation, maintenance, or repair . Its primary function is to prevent cable damage by reducing friction and tension as the cable changes direction.

-

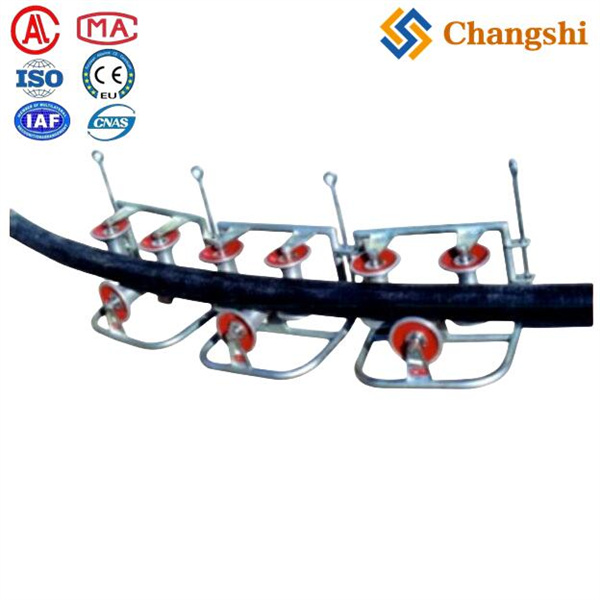

: Often features multiple rollers (e.g., three, four, or more) to distribute pressure evenly and guide the cable effectively around curves . Some have a specific curvature radius to maintain the cable's minimum bend radius .

-

: Rollers are typically made of aluminum or nylon for smooth, low-friction movement and to protect the cable sheat. Frames are commonly constructed from steel (often powder-coated or galvanized for durability and corrosion resistance) .

-

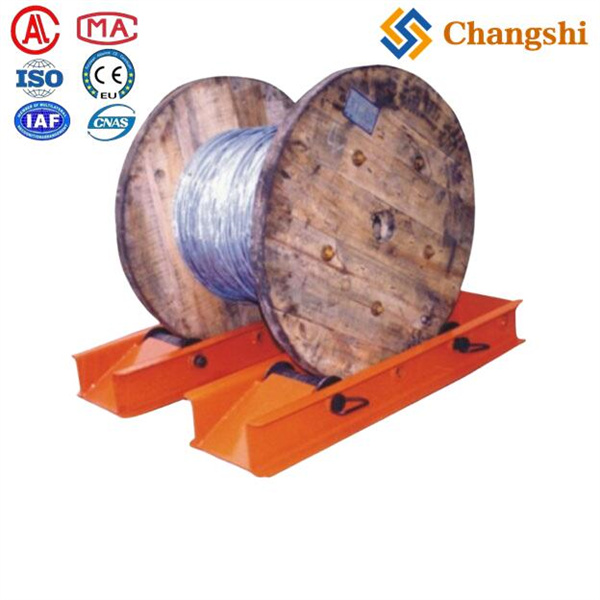

: Designed to handle significant loads, with some models capable of bearing up to 2,500 kg or 4,500 kg, making them suitable for heavy cables .

-

: Can accommodate various cable diameters, with some models handling up to 100 mm or 125 mm , and heavy-duty versions for up to 170 mm .

-

:

-

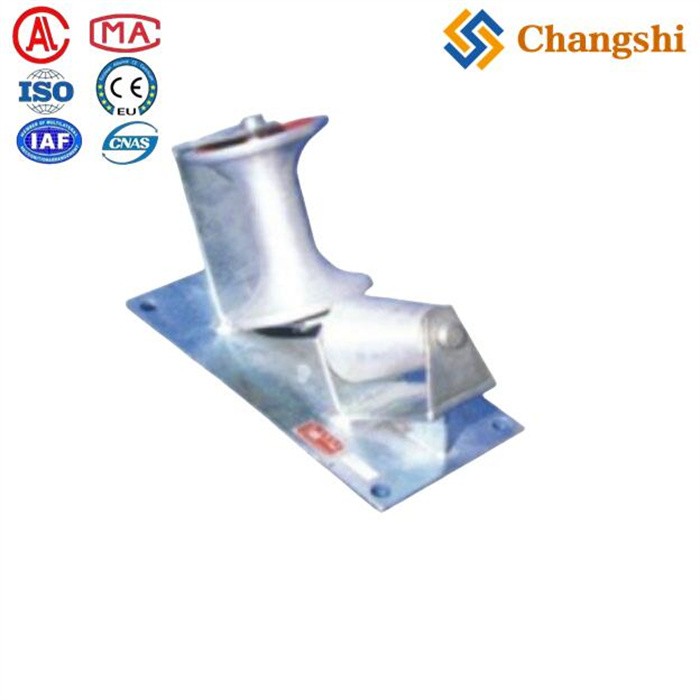

: Specifically designed to pull cables gently around sharp 90-degree corners or edges with minimal resistance .

-

: Mounted on the edge of a shaft or steps to guide cables around corners in confined spaces .

-

: Placed at the end of manhole or pit entrances to ease cable entry .

-

: Corner rollers can be connected in series to form a continuous curve, accommodating the bending radius of the cable.

-

-

:

-

: Minimizes friction and tension, protecting cables from snagging, abrasion, and kinking .

-

: Makes it easier to pull cables around difficult corners, reducing manual labor .

-

: Available in various designs and sizes for different applications, cable types, and installation environments .

Cable tuning roller

|

Order number |

Model |

Rated Load(kN) |

Structure |

|

21231 |

SHLZ1 |

10 |

One-way |

|

21232 |

SHLZ1N |

10 |

One-way |

|

21233 |

SHLZ1T |

10 |

Both-way |

|

21234 |

SHLZ1TN |

10 |

Both-way |

·notes :for small turning radius of small sectional conductors.

the model with N is nylon roller and the others are aluminous roller.

In essence, cable turning rollers are critical tools for ensuring the safe, efficient, and damage-free installation of cables, particularly where the cable route involves changes in direction