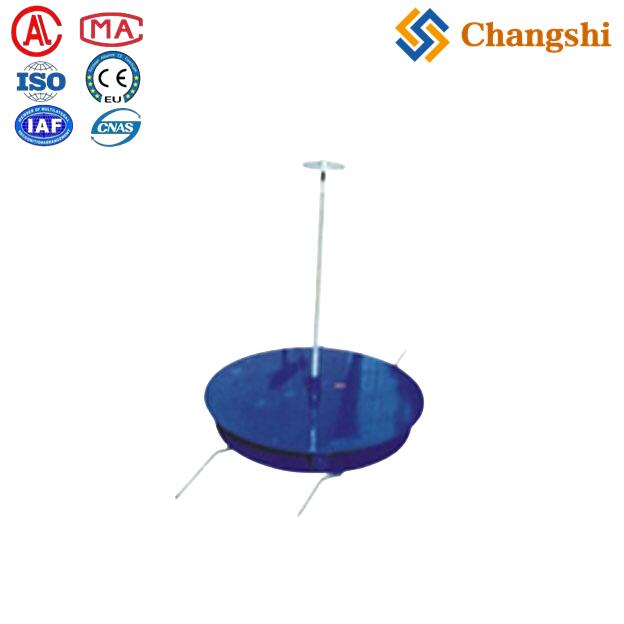

Overhead Power Lines Conductor Stringing Equipment Cables Pulling Pulley Blocks

Overhead power line conductor stringing pulley blocks are specialized tools designed to support and guide conductors during stringing operations, minimizing friction and conductor damage while enabling smooth pulling along transmission towers.

- Transmission Line Wire Cable Conductor Tension Stringing Equipment

- Transmission Conductor Tension Stringing Equipment For Overhead Power Lines

- Tools For Power Lines,Substation,Electrical Construction & Maintenance

- Electric Power Transmission Distribution Line Construction Machine Tools

- Overhead Power Transmission Distribution Line Repair Hardware Fittings

- Underground Cable Laying Pulling Installation Equipment Machine Tools Accessories

- Information

- Video

Overhead power line OHTLstringingequipment.com/Conductor-Stringing-Equipment.html target='_blank'>conductor stringing pulley blocks are specialized tools designed to support and guide conductors during stringing operations, minimizing friction and conductor damage while enabling smooth pulling along transmission towers.

-

: Commonly made from high-strength nylon (MC nylon) or aluminum alloy, often lined with neoprene to protect conductor surfaces and reduce wear.

-

: Usually constructed from galvanized steel for corrosion resistance and durability.

-

: Typical diameters range from 408 mm up to 1040 mm, with common sizes like 508 mm, 660 mm, 822 mm, 916 mm, and 1040 mm. Larger diameters reduce bending stress on conductors.

-

: Available in configurations of 1, 3, 5, 7, or 9 sheaves to accommodate single or bundled conductors. Multiple sheaves enable simultaneous stringing of bundled cables.

-

: Depending on size and design, rated loads range from about 20 kN for smaller blocks up to 120 kN or more for large multi-sheave blocks. For example, a 916x110 mm three-wheel nylon block can handle about 80 kN load for conductors up to 800 mm² cross-section.

-

: Suitable for stringing various conductors including ACSR (Aluminum Conductor Steel Reinforced), OPGW (Optical Ground Wire), and other overhead cables on transmission lines up to 500 kV or higher.

-

: Pulley blocks come with fixed, Swivel, or hook connections often equipped with safety locks. Some models include grounding devices or conductive sheaves for lightning protection.

-

: Sheaves are mounted on ball bearings for smooth rotation, and some central wheels are made of cast steel to reduce wear from wire ropes.

| Sheave Diameter (mm) | Sheave Number | Rated Load (kN) | Suitable Conductor Size (mm²) | Material Details | Typical Weight (kg) |

|---|---|---|---|---|---|

| 508 | 1-5 | 20-60 | ≤ 400 | Nylon sheaves, galvanized steel frame | 60-85 |

| 660 | 1-9 | 20-60 | ≤ 500 | Aluminum alloy or nylon sheaves lined with neoprene | ~25-106 |

| 822 | 3-9 | 60 | ≤ 630 | Aluminum alloy sheaves with neoprene lining | ~138-168 |

| 916 | 3 | 80 | ≤ 800 | Nylon sheaves, central steel sheave | ~140 |

| 1040 | 3 | 110 | ≤ 1000 | Nylon sheaves, galvanized steel frame | ~210 |

-

Large Diameter Blocks (822 mm): Used for high-voltage lines (350-500 kV), available with 1 to 7 sheaves, rated loads up to 150 kN, smooth operation with MC nylon wheels and galvanized steel frames.

-

: Used in some blocks to reduce abrasion from wire ropes, enhancing durability in extreme weather.

-

Pulley blocks are hung on transmission towers or temporary supports to guide conductors during stringing.

-

Multiple sheave blocks enable efficient stringing of bundled conductors.

-

Larger sheave diameters reduce conductor bending stress and friction.

-

Neoprene linings and high-quality materials protect conductors and extend equipment life.

-

Rated loads and sizes must be matched to conductor size and stringing tension requirements.

These pulley blocks are indispensable for safe, efficient, and damage-free overhead power line conductor installation, widely used by utilities and contractors worldwide.

If you require specific models or customization, manufacturer Ningbo Changshi offer a broad range of pulley blocks tailored to various conductor sizes and project voltages.