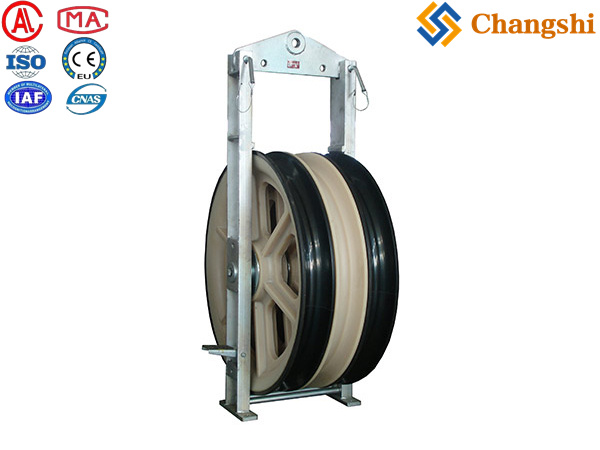

Conductor Stringing Equipment Pulley Running Out Blocks For Overhead Power Lines

Conductor stringing equipment pulley running out blocks are specialized pulley blocks used in the installation of overhead power lines to string conductors safely and efficiently. These running out blocks serve as guide pulleys that support and direct the conductor or optical fiber cables during stringing operations on both distribution and transmission power lines.

- Transmission Line Wire Cable Conductor Tension Stringing Equipment

- Transmission Conductor Tension Stringing Equipment For Overhead Power Lines

- Tools For Power Lines,Substation,Electrical Construction & Maintenance

- Electric Power Transmission Distribution Line Construction Machine Tools

- Overhead Power Transmission Distribution Line Repair Hardware Fittings

- Underground Cable Laying Pulling Installation Equipment Machine Tools Accessories

- Information

- Video

OHTLstringingequipment.com/Conductor-Stringing-Equipment.html target='_blank'>conductor stringing equipment pulley running out blocks are specialized pulley blocks used in the installation of overhead power lines to string conductors safely and efficiently. These running out blocks serve as guide pulleys that support and direct the conductor or optical fiber cables during stringing operations on both distribution and transmission power lines.

-

: Typically made with a galvanized steel frame for durability and corrosion resistance. The sheaves (pulleys) are made from materials such as aluminum alloy or high-strength nylon, often mounted on ball bearings to reduce friction and wear.

-

: Single or multiple sheaves are available depending on the conductor configuration (single or bundled conductors). Some running out blocks have nylon-lined grooves or aluminum sectors to protect the conductor.

-

: Designed to handle conductors with diameters ranging roughly from 20 mm up to 60 mm or more, with working loads from 40 kN to 150 kN depending on the model.

-

: Some blocks include non-fleeting devices to prevent conductor slippage, Swiveling hooks or fork attachments for easy mounting on towers, and ground devices for conductor grounding during installation. Specific models are adapted for Optical Ground Wire (OPGW) or fiber optic conductors.

-

: Used to support and guide conductors, OPGW, ADSS, and communication lines during stringing. They help in pulling conductors towards power towers without twisting or damaging the conductor.

-

: Available as single sheave, three sheaves, five sheaves, or more, to accommodate different conductor bundles (single to five bundled conductors).

-

: Transport boxes, special frames, hooks, and clamps are often available as optional accessories.

-

Running out blocks are critical components in the OHTLstringingequipment.com/Conductor-Stringing-Equipment.html target='_blank'>conductor stringing system, which also includes Tensioners, bull lines (pulling lines), and pullers. Their role is to guide the conductor smoothly over long spans, minimizing mechanical stress and preventing damage during installation. They are hung on power towers and allow the conductor or pulling rope to pass through their grooves, facilitating controlled conductor placement.

| Feature | Description |

|---|---|

| Frame Material | Galvanized steel |

| Sheave Material | Aluminum alloy or high-strength nylon |

| Sheave Bearings | Ball bearings for smooth rotation |

| Conductor Diameter Range | 20 mm to 60+ mm |

| Working Load | 40 kN to 150 kN |

| Sheave Configurations | Single, 3, 5 sheaves for single or bundled conductors |

| Special Options | Non-fleeting device, Swiveling hooks, grounding devices |

| Applications | Overhead conductor, OPGW, ADSS, communication lines |

| Accessories | Transport boxes, hooks, clamps |

These running out blocks are manufactured and supplied globally, with many models designed to meet stringent industry standards for safety and reliability in overhead power line construction