Aluminum Alloy Crossing Structure For Overhead Power Transmission Lines

An aluminum alloy crossing structure generally refers to a structural element or assembly made primarily from aluminum alloys, designed to provide a safe and durable crossing over obstacles such as conveyors, pipes, machinery, or terrain irregularities. These structures are widely used in industrial, civil, and infrastructure applications due to aluminum’s advantageous properties.

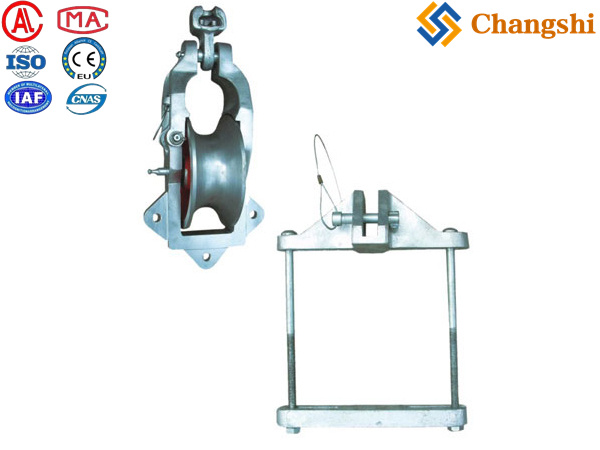

- Transmission Line Wire Cable Conductor Tension Stringing Equipment

- Transmission Conductor Tension Stringing Equipment For Overhead Power Lines

- Tools For Power Lines,Substation,Electrical Construction & Maintenance

- Electric Power Transmission Distribution Line Construction Machine Tools

- Overhead Power Transmission Distribution Line Repair Hardware Fittings

- Underground Cable Laying Pulling Installation Equipment Machine Tools Accessories

- Information

- Video

An aluminum alloy crossing structure generally refers to a structural element or assembly made primarily from aluminum alloys, designed to provide a safe and durable crossing over obstacles such as conveyors, pipes, machinery, or terrain irregularities. These structures are widely used in industrial, civil, and infrastructure applications due to aluminum’s advantageous properties.

-

: Aluminum alloys are favored for crossing structures because of their high strength-to-weight ratio, corrosion resistance, and recyclability. Aluminum’s density is about one-third that of steel, making structures lighter and easier to handle or transport. Additionally, aluminum forms a protective oxide layer that enhances corrosion resistance, important for outdoor and industrial environments.

-

: Aluminum crossing structures often use extruded or fabricated cross-sections such as hollow square or rectangular tubes, channels, or lattice frameworks. The classification and design of these cross-sections follow standards like Eurocode 9 (EC9), which define slenderness limits and load capacities for different aluminum alloy profiles.

-

: Aluminum alloy crossing structures include pedestrian crossover bridges, walkways, and platforms that allow safe passage over obstacles in workplaces or industrial sites. These structures can feature different slope angles (e.g., 50° for forward descent or 70° for space-saving designs) and various platform lengths and tread types to suit specific site needs.

-

: Aluminum is also used in composite crossing structures, where aluminum girders are combined with concrete or timber slabs to form composite beams. These composite systems improve load-bearing capacity and stiffness while reducing issues like local buckling and lateral-torsional buckling. Such composite beams are used in bridges, footbridges, and other civil engineering structures, especially where lightweight and corrosion resistance are critical.

-

:

-

Lightweight, facilitating easier installation and transport, including to remote or difficult-to-access sites.

-

Corrosion resistance, allowing use in harsh environments such as marine, chemical storage, or sewage treatment plants.

-

High thermal conductivity and good performance in cold environments.

-

Ability to be fire-protected for certain applications, though aluminum’s fire resistance is lower than steel’s, necessitating additional fireproofing measures in some cases.

-

-

: These are aluminum alloy walkways designed to span over conveyors, pipes, or machinery, providing safe access for workers. They incorporate safety features like multiple welds per stair tread for durability and offer various tread materials for optimal grip in different environments.

-

: Used in bridges and structural restoration projects, these combine aluminum girders with concrete slabs to enhance structural performance while keeping weight low. Such beams have been used in retrofitting projects like the Groslee bridge in France.

Aluminum alloy crossing structures leverage the metal’s lightweight, corrosion resistance, and structural versatility to provide safe, durable, and efficient solutions for crossing obstacles in industrial and civil engineering contexts. Their design follows established standards for aluminum cross-sections, and they can be standalone aluminum frameworks or composite systems with concrete or timber. These structures are adaptable to various environments and applications, including industrial walkways, pedestrian bridges, and structural components in composite construction.

This combination of properties and design flexibility makes aluminum alloy crossing structures a preferred choice where weight savings, corrosion resistance, and ease of installation are priorities.